|

DCC conversion

Although I have some experience with wiring,

I have to say that it is not my favourite occupation. I find that the

smallest distraction when doing the job can result in connection disasters

so I also have to put my hand up to admit that the job also makes me very

grumpy indeed! Nevertheless, I have wired up a couple of aircraft cockpits (and

flown the 'plane afterwards).

I was brought up in the era of

electro-mechanics. You could actually see what was happening in those days

and it made sense. Electronics are wonderful but my general understanding

is about that of ancient tribes observing an eclipse. Circuit boards look

to me like a mad mixture of tiny Liquorice Allsorts and Dolly Mixtures and the

sight of folks making up boards to their own design fills me with admiration.

In the old days, I had used a thing called 'pulse power'. All the locos

ran really well at scale speeds and I felt all was right in the world.

Coming back to the hobby, I found 'pulse power' was a thing of the past

and 'all it used to do was burn out motors' (funny that, because it never

happened to me). County Gate was therefore controlled using

DC with a Gaugemaster controller. This was not anything like pulse

power and the speeds of some of my locos were close to a Boeing 747 at

rotation.

By chance I met Malcolm Alberry at the Warley show. He was helping

out at the Digitrax stand and very kindly spent a great deal of time

explaining the systems to me in a way that even George Bush could

understand!

As a result, we opted for

the Digitrax system and begun a phased approach to digitalisation. We

purchased the Digitrax Zephyr, a transformer and some remote operating

stations. The Digitrax Zephyr manual can be downloaded

here.

Our

expectations of DCC were as follows:

-

Constant higher voltage

applied to the track. This has got to solve some of the poor conductivity

problems of DC when very slow running is required.

-

Simplified wiring as it

is not necessary to isolate track to prevent the wrong locos from

running.

-

Realistic stopping and

starting.

-

Loco performance

programmed into the chip to control top speed.

-

'cruise control' so that

the required speed is held 'up hill and down dale' whatever the load.

-

Equalisation of

performance of our L&B locos to ensure easy double heading.

-

Easier automatic

operation of the layout for exhibition purposes.

the

reality, after living with these systems is this:

-

I do not think there is

much difference in track conductivity between DCC and DC in practice

-

The wiring for a basic

system is indeed simple.

-

The locos are indeed

easier to control

-

Basic programming of a

loco is simple but it gets very difficult if you want the best

-

'cruise control'

(back EMF) might work if you make a life's work out of it but so far no

luck for me

-

It is possible to

equalise loco performance

-

Automation works very

well but the system is very complicated and expensive

I had wished to replace

the Peco solenoid motors at County Gate Station for some time and the

changeover seemed like an ideal opportunity to get that done and also to

upgrade our signals. We first of all stripped County Gate of its

wiring and Peco point motors. Feed to the track was by self adhesive

copper tape, and drop wires were put in place every metre. The amount of

wires underneath were reduced by at least 75%. I was also unhappy with

the signals at County Gate and decided to replace some of them with more

typical SR models and at the same time seek better movement and the

'bounce' found on the prototype when they are operated.

I also had got really fed

up with the permanent magnets fitted into the track to disconnect the

Greenwich couplings during shunting operations. This had resulted in a

number of involuntary disconnections at embarrassing moments. The magnets were dug out of the

track and eventually I found electromagnets strong enough to replace them.

I decided to retain the

manual operation of points and signals at this time. As such, the wiring

is indeed very simple.

The only things I have had

chipped previously are my cats. Perhaps the digital control will keep

them in order too!

Click here to check it out

Locomotives running on DC are about as clever

as a bag of hammers. When chipped, locos are far more intelligent than

George Bush! The new

chips are really very small and we were advised to choose the latest

Digitrax offering. The new Digitrax DZ 125 chip is similar in

size to the Lenz silver mini. This chip,

despite the instructions that come with it, is enabled for back EMF (BEMF)

(called 'scalable speed stabilisation' by the Yanks).

DZ 125

This offers better slow speed running and

also compensates for grades (a bit like cruise control).

At long last, the chips arrived and the exacting job of fitting them to our locomotives began. It was

necessary to virtually rebuild some of the older engines, and installation

into the L&B units was far from easy. Great care is needed to ensure that

there are no shorts in the system.

Chips can actually control other functions

too such as directional lighting. We have installed this on a few units

and it works very well indeed. The large amount of wiring needed to do

this raises challenges when working with such tiny rolling stock. I do

intend to fit sound to one unit, just for the hell of it!

The generic manual for these Digitrax chips

can be found

here

and the specific manual for the DZ125,

here

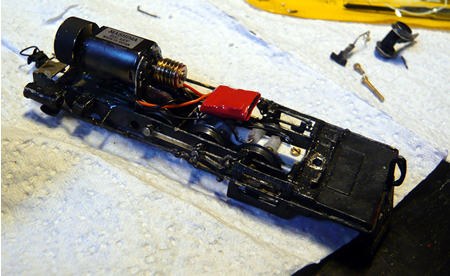

chip fitted to the

chassis of 'Taw' - click on image to enlarge

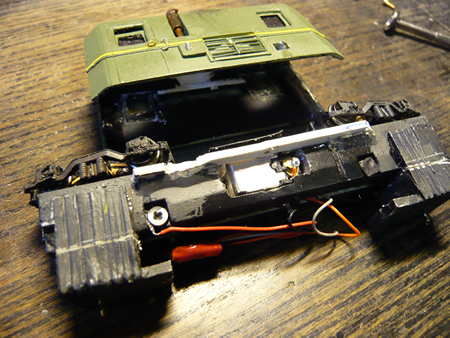

The motor unit of

the railcar converted. The part of the chassis which contacted the brushes had to be milled

away and the wires then attached to the brushes - click on image to enlarge

Once the Digitrax Zephyr outfit was

delivered, it was installed into the viaduct section of the model. The

main control box was fitted into a recess cut into the front of the

baseboard. This box is held in place with Velcro. In order to programme

locos, it is necessary to have a programming track...two leads come from

the control box to do this. We felt that this was another complication, so

the harbour branch of the viaduct section is fed through a double pole, double throw

switch to provide either track power or programming.

The leads to the UP5 remote sockets daisy

chain from the main controller. It is transferred from one panel to the

next using 8 pin DIN plugs/sockets. These also carry the track power.

the main control box

fitted. Below is the switch to track for programming or power. The DIN

socket will feed to the harbour section

The box was 'lit up' and I have to say we

quite quickly got the hang of it. All the locos now had their numbers and

can be programmed to perform as required up to a point.

DCC promises to offer all

the characteristics that I required and there is no doubt you can programme each engine to do most things.

The programming of a loco

depends on altering a vast number of parameters. These are called CVs and

there are well over one hundred of them. These all have to fiddled with on

a programming track while your supper goes cold. In my opinion, a lot more

has to be devised to make the system user friendly.

DCC manuals seem to have been written by electronic nerds for

electronic nerds (or USA speak). I have to say that Lenz scores slightly

better in this respect, but Digitrax and NCE just make my eyes roll. Some

of the information is actually wrong and there is no logic (understandable

to British and French) to the way the manual is compiled.

There are a number of

forums available where help is at hand and this does ease the situation.

Thanks to some good

friends who are in to all of this we hope to be able to publish here the

generalised programming necessary to get narrow gauge locos to run as they

should.

Bitter experience has

shown us that it is a very bad idea to use Peco point motors or others

requiring a CDU. In 20/20 hindsight, I would have fitted Tortoise

throughout.

I find that operating trains for two whole

days during exhibitions, mind numbingly boring and subject to human error

which quite often results in derailments and wrecks! Our little engines

are very delicate and such treatment was not doing them any good. Our

Desperados have been amazing doing as well as they have and have manually

operated CG far better than I could in a million years but it has been

very hard for them at best.

'mind numbingly boring'

Far better to be able

to talk without distraction to the visitors and even have the time to

visit other stands and spend time talking to old friends. I also quite liked the idea

of just watching trains go by. I therefore decided that the layout would be fitted with

automatic train control so only the port branch coal trains and shunting would be operated by hand.

After further discussions with Malcolm

Alberry, it was decided to go the whole hog. This was a very scary

decision as the equipment is not cheap and I would not have had a chance

of succeeding without Malcolm's help. It must be pointed out that

automatic running is useless unless you have reliable operation. This has

taken a great deal of time but I can now say that we have as close to 100%

train reliability as is possible.

This has been achieved by picking up

current from as many wheels as possible. Our six coupled engines are

therefore plugged in to 'companion cars' which also pick up current. Many

modifications have also been made to the mechanisms which must travel long

distances without complaint.

I still wished to retain the potential for

manual operation of the layout without depending on electronics. This

means that we have double control panels and it is possible to change from

one system to the other by merely swapping a few plugs.

I shall try to describe how it all works

without the use of too many nerdy terms! Apologies to those who know all

of this stuff!

Apart from just controlling trains, the DCC

system also includes Loconet. Loconet is a system that allows all sorts of

electronics to be daisy chained together with a six wire cable using phone

socket / plugs. Once connected, the various electronic boards are able to 'talk' to

each other. Remember, on a DCC layout, the track remains live with a

pecial DCC voltage waveform the

whole time. Digital signals are passed down the rails to the locos which

control their operation after they are 'read' by the chip. This is how

loco lights can be switched on and off, and speed and direction control is

effected. Digital signals are also passed down through the Loconet system

and provided the right bits of electronics are provided, the digital

stream can control point, signal and block operations as well as provide

for further train control stations.

Using such systems, the DCC control board is

just fitted with push buttons. The direction of point throws and signal

positions are shown by LEDs.

Sections can be cut into one rail (must be

the same side throughout the layout) and the system can sense where trains

are, which are also shown by LEDs. It is not that dissimilar to full scale

track circuiting. The image below shows how such units fit together

on County Gate.

click on image to enlarge

Parts are Digitrax, supplied by

Sunningwell Command

Control and

CML Electronics

hover over each board for explanation - do

not click All these boards are

multi-functional and some require programming which is rather difficult.

This facility allows us to

control the entire functions of the layout through just one cable (similar

to a telephone cable). The amount of wiring is thus considerably reduced.

Once this is done, by using an interface unit, the

Locobuffer, the

whole network can be connected to a computer, using USB leads. Really complex sequencing of train operation can

then take place. The

whole concept is in effect similar to sequencing and MIDI, for those

familiar with modern musical keyboard systems. The controlling software is

supplied by Railroad &

Co. This is a very flexible system and has an excellent 'help'

forum for the sticky questions. One also has to load a Loconet programme into the

laptop.

Our first show as an

automated railway was at Chatham in June 2009 and I am pleased to be able

to say that the system worked perfectly throughout the weekend.

We do have full wiring

diagrams of County Gate. These are included for our own reference should

problems arise. However, they may give some insight into the work that has

gone into this project.

The software is well explained on

this link

Below is shown a simplified animation of how

the software operates. The route is previously set for Lyn and River Avon.

The red dot shows point motors when activated. After

the railcar and Yeo return to base, Exe and Halliday would be dispatched.

click on image to repeat

Here is an animation of how the ten trains

operate over the main line.

the fiddle yard with stock arranged for auto

running

example of 10 train operation - click on image to enlarge

A film of the completed

automatic operation can be

seen here

|