|

wiring DCC points

I am asked so often how to wire up DCC points

that I am now including this piece. Unlike DC wiring, the track remains

live throughout at all times. The downside is that it is only too easy to

drive a train into a point that is set against it. This can be prevented

by extending the length of the isolated sections of the frog.

This is the simplicity of DCC as you no

longer have to worry about isolating sidings in order to stop the wrong

locos working as you choose the loco you wish to operate by selecting its

address. If the layout is already wired for DC, it will almost certainly

work for DCC as well, by the way. The only problem will be that you won't

be able to run another loco on one of the isolated track sections.

So let us first look at the basic wiring

requirement.

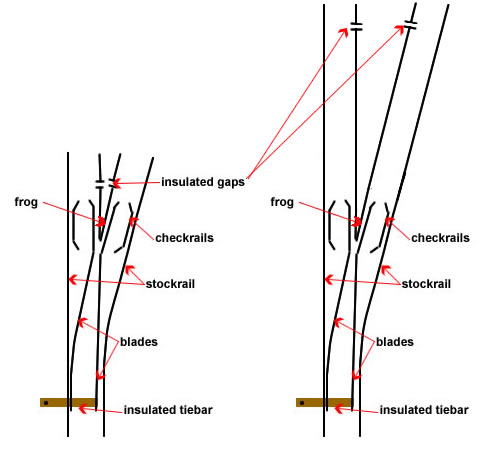

The only thing we have to do is to change the polarity of the frog

and blades when the running

direction is changed. This means that the frog must have insulated joints

to prevent a short circuit. Click on the switch below to animate.

DC

turnout

- click on switch to

operate

Despite many articles that

describe 'DCC Friendly' points, I did not bother to install them because

if you

are using Peco 'Crazy track' points it is extremely difficult to do so.

Just to explain what DCC friendly points are.

Some people are concerned that when running DCC which has a slightly

higher voltage (15VAC), a wheel might short circuit between the blade and

stock rail, so they add an additional rail break so the the blades are

always the same polarity as the adjacent stock rail. Indeed, learned

article abound on the web about 'friendly' points. Again, click on the

switch to see operation.

The new range of Peco 'Mainline' points are

excellent and can be transformed to DCC friendly in minutes. It is

therefore worth while doing so.

DCC 'friendly turnout' -

click on switch to operate

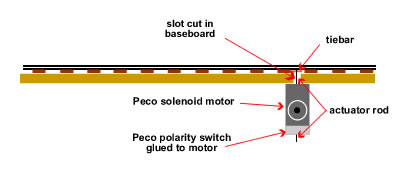

So lets look at the installation using Peco

point solenoids and polarity switch. Firstly, I solder a 'dropper' (a thin

length of wire) soldered on the underside of the frog. Once the exact

position of the point has been established, drill a hole in the baseboard

to allow the dropper to pass to the underside and drill a slot to give

adequate clearance for the actuating rod which passes through the hole in

the tiebar. The point is then fitted and fastened down (I just epoxy them

onto the baseboard). The fishplates are soldered to the adjacent rails but

do not forget to use insulating fishplates on both sides of the frog.

I then temporarily wire up the solenoid

including a switch and then epoxy the motor to the underside of the

baseboard. I make sure that the blade are held midway between the stock

rails and that the actuating rod is at the centre of the slot. As the glue

begins to go off, I operate the point and adjust if necessary to ensure

that there is an equal throw and that the blades go fully over.

Once the glue has gone off, I add the

polarity switch which I also glue on.

-

Make sure that the motor

is placed at the centre of the throw. If it is not, you will see the

actuating rod bounce back toward the centre. If this happens, the

polarity switch will not operate.

-

If you do have to remove

a glued solenoid motor, a couple of light taps with a chisel will release

it.

You are then ready for final wiring. The Peco

solenoid motor is operated through a Capacitor Discharge Unit (CDU). This

gives a good belt of electricity which powers the solenoid. CDUs are

powered from a 15V AC transformer. You must use a momentary contact switch

as holding power onto the solenoids will burn them out. Click on switch to

operate the image below.

The Peco turnout maintains blade position by

a small spring hidden near the tie bar. These can fail and the system will

no longer properly hold the blades in place. If this happens, you can

replace the Peco motor with a latching Seep motor which is available from

Gaugemaster. The wiring is the same.

|

Peco

solenoid point motors and route setting |

In 20:20 hindsight, I made a big error in

using Peco point motors on the fiddle yard. We use DAC 10s (CML) and DS44s

(Digitrax) to operate the point motors. There is the facility to set these

units for operating solenoid motors as they have built in CDUs, however

the signal was just not strong enough to operate the points. We therefore

had to use the signal to operate relays connected to a large CDU in the

fiddle yard.

This worked but required a four second delay

in operation between each point actuation when routes were being set by

the Railroad & Co software. This much delayed the time when trains were

not operating on the line.

In the end, we have also been forced to add

individual CDUs to every point. This has meant that three 24V AC power

units are needed to operate them but at last, the routes can be set in

'rapid fire'. Altogether a big mistake and we should have used Tortoise

motors to avoid the problem in the first place.

Hex

Frog Juicer (HFJ)

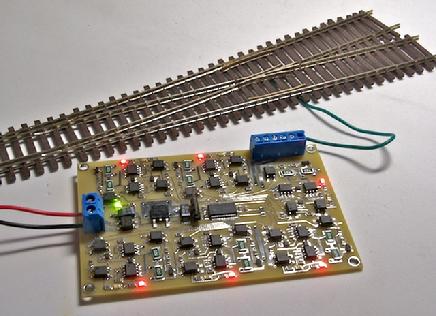

So this mad sounding piece of electronics is

duly installed. Delivered from

Digitrains, I

am happy to say that it does just what it says on the box. The polarity

switches on my Seep motors were retained to continue operating the point

position lights on our switchboard. The droppers from the frogs were

attached to the HFJ and the HFJ was wired to track power. Nothing could

have been easier.

the six point unit as fitted to CG

Under test, the polarity changed instantly

and the momentary short was not registered either by the trains,

Digitrax system or the Railroad & Co software. A perfect result in fact.

The unit is not cheap but if one is looking for 100% long term

reliability, well worth the cost of £8 a point in my opinion. Single and

double units are also available. The LED light show is quite impressive:

pity it is hidden under the baseboard!

The unit also does miracles for more

complicated trackwork such as crossings and slips.

|