|

Building the third prototype

railcar (302)

a railcar meeting -

click on image to enlarge

The experience gained

operating the prototype railcars No 200 and 201 enabled Eastleigh to

finalise their design and a final prototype car was built at Eastleigh, No

302.

The third car included a parcels compartment and first class

seating.

Cooling was moved from the

tractor car sides to the roof in this series.

The basis for the railcar

was the Riverossi N scale diesel loco chassis which had previously

been used in the now scrapped railcar 202.

The leading bogie of our

railcars must reliably collect current from both rails in order that under

automation, the units stop and start at the correct positions on our

fiddle yards and platforms.

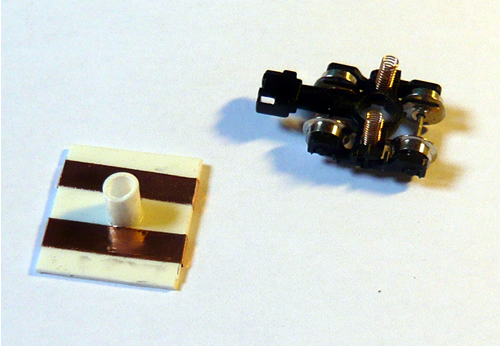

We have used bogies which

are normally supplied with the Tomix N scale track cleaners. They were

kindly sent to me by Dapol. The current collection springs transfer to

copper tape attached to the rubbing plate. The end result is a very

effective sprung bogie.

The bolster plate made in

plastic and the Tomix bogie.

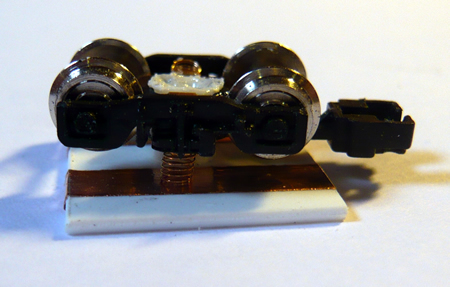

The made up bogie unit

Construction methods are

largely similar to the first railcar. We built up the complex curves using

soft sand bodyfiller.

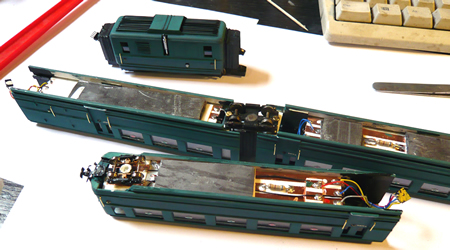

the completed bodies under construction- click image to enlarge

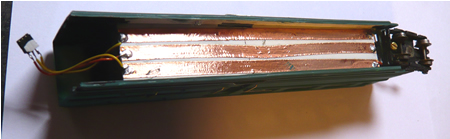

the underside of the first class unit

which shows the articulated bogie - click image to enlarge

the railcar underside with lead ballast

weight added - click image to enlarge

approaching completion

The front of 302 showing Kent 'Clearview' screen

click image to enlarge

|