|

Building the Kitson Meyer

The Meyer design was reworked by Kitson who moved the

bogies apart sufficiently to allow for a conventional firebox and grate

to fit between them. As such, they were one of the most successful

articulated designs in the world. A freelance Kitson Meyer was developed

using many of the features of the Leek and Manifold tank engines, that I

so much admire.

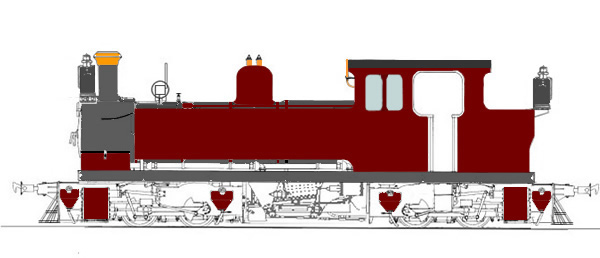

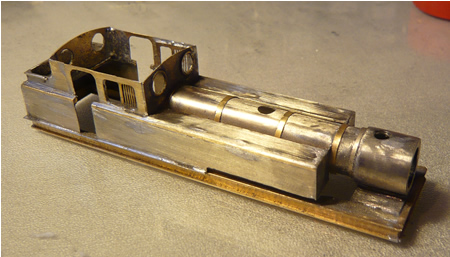

the design is getting

close to looking right. There is a great deal of the Leek and Manifold

tank in the design!

the design is getting

close to looking right. There is a great deal of the Leek and Manifold

tank in the design!

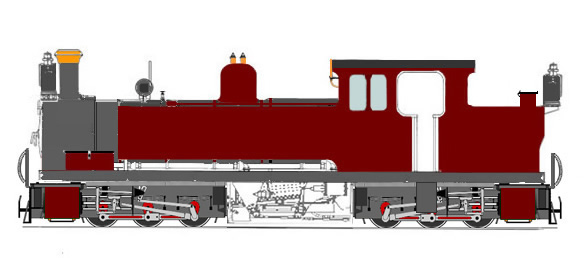

this is the same design

with Grafar 08 chassis

this is the same design

with Grafar 08 chassis

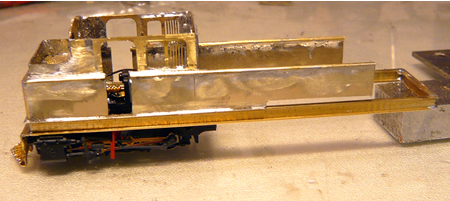

this is a photo mock-up

of the engine

this is a photo mock-up

of the engine

This build is one of my typical freelance

jobs. Mostly I worked from the photo mock-up that I made and very few

measurements were actually taken. In a way, like the Mallets, it has

been more of a loco sculpture than anything else but for me, I find it

easier to get the proportions looking right this way.

The loco was built with the most basic of

equipment: a Dremel, 25 watt soldering iron and some hand tools and of

course the wife's best kitchen scissors.

The fixed dimensions were the Bachmann

class 08 bogies, the side windows and spectacle plates left over from

Backwoods Manning Wardle kits and the rest more or less fell into place

on its own.

The first job was to graft the Roco valve

gear and cylinders onto the Bachmann class 08 chassis. The rear part of

each chassis was removed. Normally, the Roco valve gear stands higher

than the platform of the 08 chassis.

The 'comfortable' position for the valve

gear

The 'comfortable' position for the valve

gear

In this case, it could not be allowed

otherwise the loco would look like it was on stilts. Some butchery was

needed including the shortening of the expansion links so that the whole

lot did not protrude higher that the chassis footplate. In the end, with

a lot of fiddling, it all worked freely.

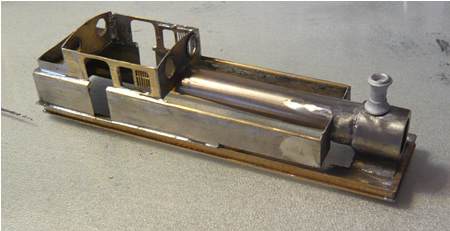

The main frame

which supports the boiler and cab was then soldered up. This was an

'I'

section purchased from

Eileen's Emporium. I always work on a sheet of glass in order to make

sure everything goes together perfectly flat.

click on image to

enlarge

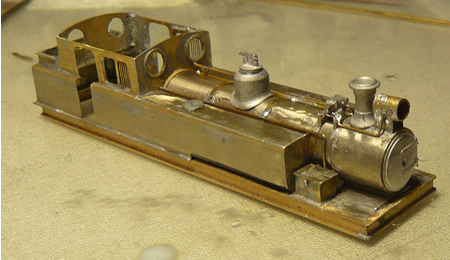

Due to the variations and evolutions of the

L&B Manning Wardles, quite a few etchings are never used. I selected the

cab etching for the locos as originally built and cut the window

sections out. These were butt soldered to nickel silver off cuts

from coach kits and the whole cut to the correct shape. The main feature

of this loco are the curved tank tops and waisted cab. This was achieved

by soldering a thick brass wire to the cab and then soldering the tanks

on the opposite side of the rod. This done of a sheet of glass results

in a perfect job.

For the time being, I left the rod crossing

the cab entrance in order to keep the whole thing in shape.

the finished result

the finished result

The window frames were added followed by

the spectacle plates (brass surrounds soldered in first) and the whole

assembly soldered up. Take care to ensure that it it all squared up.

the assembly is then

soldered to the frame

-

click on image to enlarge

the assembly is then

soldered to the frame

-

click on image to enlarge

The smoke box and boiler top was made

simply by heating the metal sheet and wrapping it around a former.

smokebox and boiler

rolled and fitted - click on image to enlarge

smokebox and boiler

rolled and fitted - click on image to enlarge

the tank tops are then

added

the tank tops are then

added

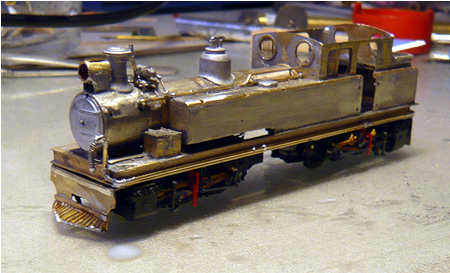

generator fitted along

with tool boxes - click on image to enlarge

generator fitted along

with tool boxes - click on image to enlarge

click on image to

enlarge

click on image to

enlarge

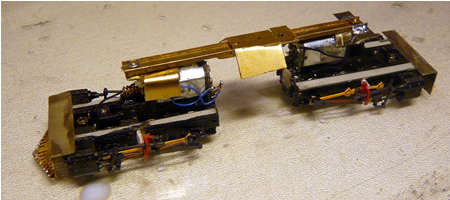

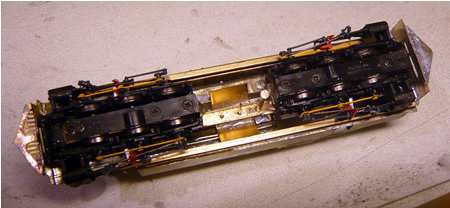

The two bogies have to be insulated from

one another as they will be of opposite polarity. The brass saddles

which fit over the motors, (with the pivot over the centre driver) are

coated with epoxy and when dry, the saddles are epoxied onto the motors,

ensuring that the rubbing plates are perfectly flat. The front bogie

(left) is left more free moving by placing a thin washer between the

rubbing plates. The rear, however. is stabilised much more with wide

running plates to prevent the loco rolling.

click on image to

enlarge

click on image to

enlarge

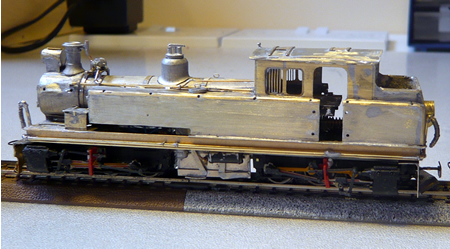

The chassis is fitted into the body using

two locating pins and an extended screw to make assembly easy. The

firebox will be built up from the visible 'wings'.

click on image to

enlarge

click on image to

enlarge

This is the loco which is now ready for

painting. The handrails will be fitted later. One of the tough jobs was

the drilling of handrail knob holes through the thick brass rod that

forms the tank top curve. The result was much larger holes than I

wished. This was cured by refilling the holes with solder and then

drilling the right size.

click on image to

enlarge

click on image to

enlarge

This is the size comparison with our

Mallets and Garratt.

I have experienced several loose wheels. This

is what I suggest:

On initial stripdown, degrease axles and wheels and run into the wheel

boss, a small quantity of Locktight 603 and leave overnight. This should

prevent these stupidities.

Several phosphor bronze are often on in contact with the wheels....check

for this..

Positioning of the Roco cylinders. Remove

motor. Use 5 minute epoxy to attach and have the return crank already

fitted into the rear crank. There is then a short window of opportunity to

ensure that there is free movement of the gear.

Once the cylinders are fastened, push the chassis along to check for any

binding between the coupling rod and the slide bar support bracket. Only

then replace the motor but glue this in position as well, as the extra

weight of the valve gear can cause the motor to 'jump' and strip the

gears.

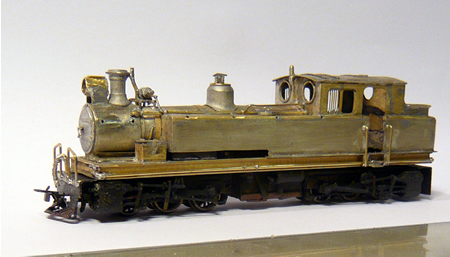

After looking at the loco for a few hours,

I have changed a few things. The safety valves (which came from a

Langley 'Lyn' dome) looked crude so they were replaced with a scratch

built version. As indeed was done with a number of these locos which

suffered from loading gauge issues, the footplate floor has been 'underslung'

to the bottom of the support frame and the hand rails extended down

lower than originally planned. Finally, the front vacuum pipe has been

transferred to the bogie and rails placed on the pilot in a similar

manner to many Mallets. Several Kitson Meyers carried them and it must

have been far easier to work in the smokebox.

Finally, I have turned a proper whistle

using brass rod in my Dremel.

click on image to enlarge

After the fitting of the sandboxes, made of

thick Plasticard, The body was placed in the ultrasonic cleaner with a

tiny touch of soda to neutralise the flux, followed by a clean rinse.

Once dry, the body was sprayed with etch primer.

At this point we had some chip issues but

thanks to Andy of DCC Supplies, the problem was quickly resolved. The

handrails have been temporarily fitted and very shortly, it will be off

for finishing and lining.

The loco has been lined and weathered in a

first class fashion by

Robert

Kaczmarczyk who is available for custom projects. It has now joined

the fleet and I must say, runs most smoothly despite a slight 'waddle'.

This locomotive has covered quite a mileage

and has waddled all the way. I suspected an out of round wheelset but

this was not the case. It would appear that the high pivot point needed

to create the Kitson Meyer configuration causes the valve gear loading

to be magnified. Another modeller has made an excellent similar model

and it also waddles! Case is proven.

The lovely model built

by Phil Mortimer in the USA.

The lovely model built

by Phil Mortimer in the USA.

The problem has been solved by stabilizing

the wheels using plastic strip attached to the outside frame with epoxy

glue. The moulded hornblocks are first trimmed off. This has much

mitigated the problem.

|