|

Building 'River Avill' No 797

see movie of this loco in action

Well known modeller, Bernard Taylor came up

with a drawing of an Armstrong Whitworth narrow gauge diesel electric

locomotive of the early 1930s. He then went ahead and has just produced

some first class etches of the model. It is designed to fit on the

Bachmann Class 08 chassis.

click on image to enlarge

If Eastleigh had wished to experiment with

this concept, as well as its new railcar programme, a single unit would

have been inadequate. They would have expected at least as much traction

as produced by their Mallet design. I have therefore redrawn the loco as

a double articulated unit.

click on image to enlarge

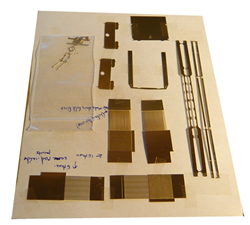

Bernard very kindly drew out a different

front which in my mind was more appropriate to fit in with the Eastleigh

design concepts. We received the first set of etchings, and very nice

they are too.

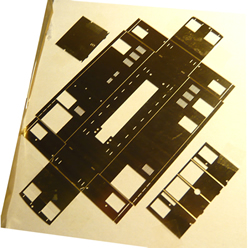

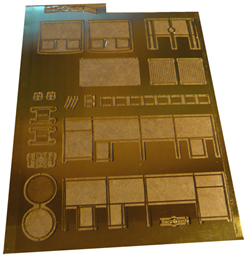

click on images to enlarge

click on images to enlarge

click on image to enlarge

click on image to enlarge

small part identification -

click on image to enlarge

small part identification -

click on image to enlarge

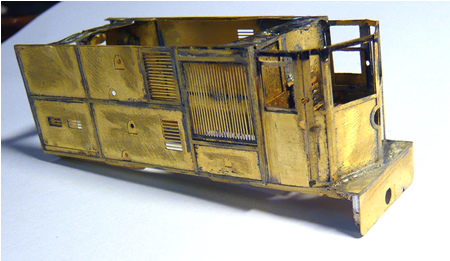

The test etch from Bernard , I must admit

contains many lovely bits which frankly I cannot figure out where they

go! I am sure that this will be resolved once this kit goes on sale.

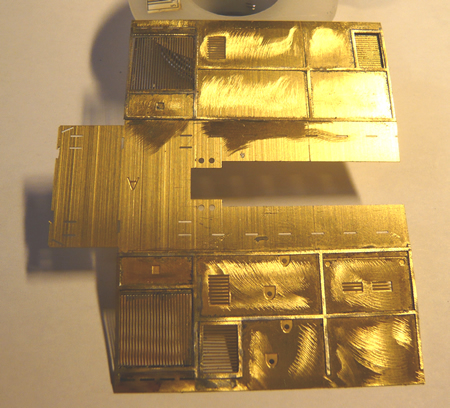

Seeing as my own model is going to be quite different, I have ploughed

my own furrow. After cutting the fret to remove one panel, the first job

was to sweat on the panelling. Great care is needed to prevent solder

spreading around. The grills were soldered at the rear.

click on image to enlarge

click on image to enlarge

click on image to enlarge

click on image to enlarge

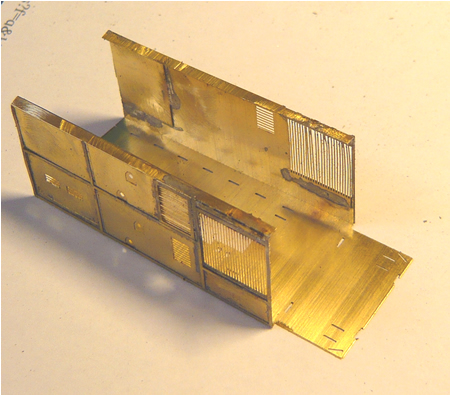

The fret was then folded using a bending

tool. Bernard was kind enough to include a different front which I felt

was more in keeping with the County Gate style. This was also folded as

was the outer panelling. The front was then soldered to the assembly.

click on image to enlarge

click on image to enlarge

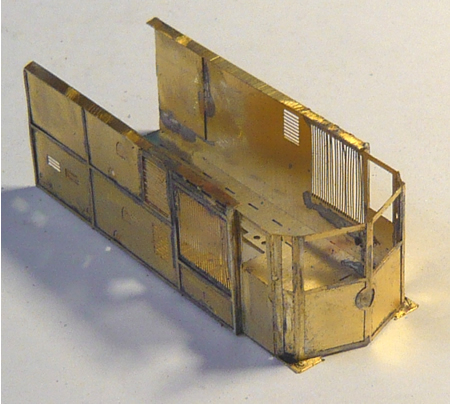

The buffer beam and lower valance were then

attached. To cross members were soldered at roof height with captive

nuts to attach the roof.

click on image to enlarge

click on image to enlarge

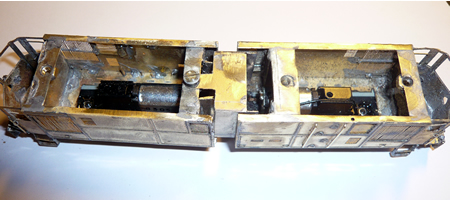

The roof is made from flat brass sheet. The

profile of the roof is built up from car body filler. Below, the body is

on the outside frames of a class 08 chassis.

click on image to enlarge

click on image to enlarge

as far as we can go for now - click on image to enlarge

as far as we can go for now - click on image to enlarge

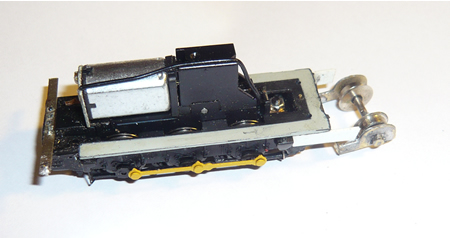

The second fret arrived and shortly

afterwards, two Bachmann chassis and a cow catcher set from Langley. The

next body went together nicely. As the two chassis are to be operated

back to back, the wiring of one needs to be reversed. The coupling box

at the front of each chassis was removed and a small hole drilled

through the chassis to take a fine brass wire that will become the pony

truck pivot pin.

The pony truck was fabricated from the four

wheel bogies supplied. Axle boxes were made out of small bore brass tube

filled with solder. A fine hole was drilled in these to take the needle

point wheel sets.

I have experienced several loose wheels. This

is what I suggest:

On initial stripdown, degrease axles and wheels and run into the wheel

boss, a small quantity of Locktight 603 and leave overnight. This should

prevent these stupidities.

Several phosphor bronze are often on in contact with the wheels....check

for this..

Positioning of the Roco cylinders. Remove

motor. Use 5 minute epoxy to attach and have the return crank already

fitted into the rear crank. There is then a short window of opportunity to

ensure that there is free movement of the gear.

Once the cylinders are fastened, push the chassis along to check for any

binding between the coupling rod and the slide bar support bracket. Only

then replace the motor but glue this in position as well, as the extra

weight of the valve gear can cause the motor to 'jump' and strip the

gears.

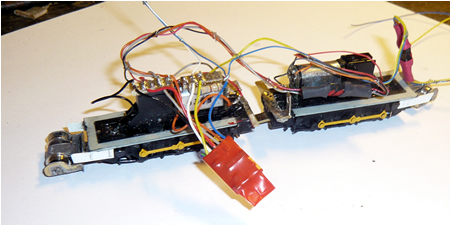

Chassis with pony truck fitted. The chassis is extended with plastic

strip.

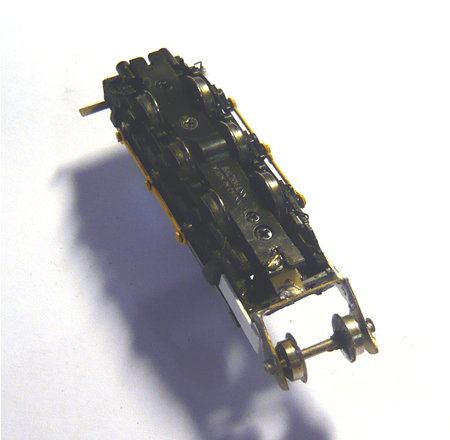

the underside of the chassis. One wheel

has been grounded to the axle. The pony truck is yet to be weighted.

the underside of the chassis. One wheel

has been grounded to the axle. The pony truck is yet to be weighted.

The modified keeper plate showing

pony truck retainer pin. The height of the pony truck pivot will be

maintained with a spacer.

- click on image to enlarge

The modified keeper plate showing

pony truck retainer pin. The height of the pony truck pivot will be

maintained with a spacer.

- click on image to enlarge

The start of building the steel corridor connection. To prevent short

circuiting between the two opposite polarity bodies, much of the

corridor connection had to be replaced by plastic. - click on image to

enlarge

The start of building the steel corridor connection. To prevent short

circuiting between the two opposite polarity bodies, much of the

corridor connection had to be replaced by plastic. - click on image to

enlarge

The pony trucks are now weighted with lead and the chassis link added. I

realised afterwards that the two chassis are of opposite polarity, so

the drawbar had to be divided with a plastic centre section -

click on image to enlarge

The pony trucks are now weighted with lead and the chassis link added. I

realised afterwards that the two chassis are of opposite polarity, so

the drawbar had to be divided with a plastic centre section -

click on image to enlarge

The chassis are wired up to a DZ 143 Digitrax chip. The extra

wiring is for the directional lighting- click on image to enlarge

The chassis are wired up to a DZ 143 Digitrax chip. The extra

wiring is for the directional lighting- click on image to enlarge

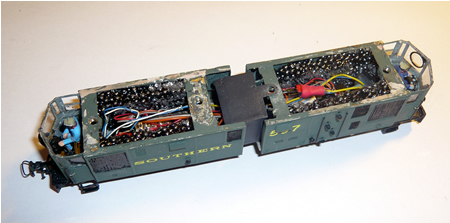

The bodies have been painted and detailed and the interior cavity

filled with lead shot wherever possible!- click on image to enlarge

The bodies have been painted and detailed and the interior cavity

filled with lead shot wherever possible!- click on image to enlarge

the completed 'River Avill' on Simon Coward's Isle of Mudd layout- click on image to enlarge

the completed 'River Avill' on Simon Coward's Isle of Mudd layout- click on image to enlarge

photo by Mick Thornton

|