|

The beauty of brass

“All dust is the same

dust.

Temporarily separated

To go peacefully

And enjoy the eternal nap.”

― Dejan Stojanovic

That is possibly true, but

what do you think will last the longest; a plastic model or one properly

built in brass or nickel silver? Plastic has a habit of gradually losing its

properties and becoming brittle. This is because the molecules begin to join

up with those alongside: this is called polymerization. The phenomenon is

accelerated by exposure to ultra violate light but will happen all on its

own, given time. I have a drawer full of old plastic chassis parts that have

cracked and become useless. I doubt I am the only one.

Pick up a locomotive made of

plastic and it will feel not too different to a child's toy straight from

Mothercraft'.

A ready to run well detailed

plastic model locomotive may well look the part and no doubt will outlive

some of us old duffers but will you feel a sense of satisfaction when you

handle it? Add to this the question of ballast weight. Model locomotives

need to be heavy to prevent the driving wheels from slipping. It is of

course possible to add traction tyres to mitigate this but it comes at the

cost of reliability and loss of electrical pickup.

Then, of course, there is

the emotional reaction. Steam engines are heavy and robust things made of

metal. For me, I like my models to be the same! I just cannot accept that

bits of plastic stuck together is a robust solution.

So why is it that less and

less modellers learn to solder and make 'proper' model locomotives?

I think some of it is that

some are fearful of learning new skills although soldering is very straight

forward. Health and safety does not help matters either. As soldering flux

gets 'safer' and 'safer' it also becomes less and less effective. I still

use Bakers fluid which always works. The other problem is that many solders

are now lead free and are completely hopeless and last but a short time

before breaking up.

see

art of soldering

So what is so mysterious

about building in brass?

Absolutely nothing but some

still make a huge meal of the whole affair. The principles were laid down by

John Ahern in his book 'Miniature Locomotive Construction' back in the 1950s

and it has just become easier and easier since then. Nowadays, a vast

selection of brass sheets, sections and tubes are available from suppliers.

A huge choice of castings can be purchased both in lost wax brass and white

metal. Modern simple power tools complete the picture.

soldering

The first thing is to make

sure that you get enough heat to the work QUICKLY. Many people use far too

small irons and manage to unsolder everything else before succeeding in

getting the area to be soldered hot enough. For most loco building, one

needs three irons: 40, 25 and 18 watt. It is useful to have a choice of tips

that can easily be interchanged. I see little point in expensive temperature

controlled units and just buy cheap Antex units from Expo Tools.

Flux which works is also

essential. I use Bakers soldering fluid No 3. I pour a little in a jar and

apply it with a brush. It is strong and one must not get it on one's face.

The work needs to be washed regularly with hot water and detergent as does

one's hands.

Solder MUST be proper lead

based solder. This is still available in proper electronics suppliers. Lead

free solder breaks down into powder in very little time and solders very

badly in any case.

practice

If you have not soldered

before, practice first on bits of brass and learn how to get a good joint

without excess solder. If the work looks like bird droppings, you are not

using the right flux or have insufficient heat to the work.

It is then worth while

starting to build a simple etched brass kit and work up from there. Bit by

bit, one collects a lot of spare etches and parts from early failed

projects. These become invaluable later as ready made parts for new locos.

tools

The only power tool I use is

a Zircon mini drill and regulator bought from Expo Tools. It is the only one

I have found to be any good but still needs a spot of maintenance and I

occasionally have the replace the motor, which costs just a few pounds. When

loco building, it is in use almost all of the time. I use a selection of

burrs, minidrills and Proxon cut-off discs and sanding discs. I cut

most of my metal with this tool and do most of my building using it. I hate

doing things by hand when power tools will do the trick.

I also have a metal bender

which is just two stout bars which one can screw together, and a selection

of small files, screwdrivers and engraver's chisels. I also have 10 and 12

BA taps which are heavily used.

I have a small vice and a

few other bits and pieces but no more than the average modeller. There is no

excuse not to build in brass!

Perhaps also there is a

current trend of instant gratification which usually results in no

gratification at all. Metal locomotives are just as fast to build once the

skills are learned and are things that will last through generations.

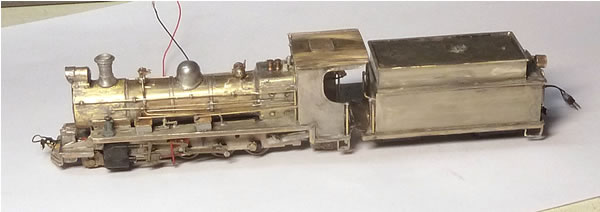

This Gwalior Mikado was built in one week based on a Grafar class 08 chassis

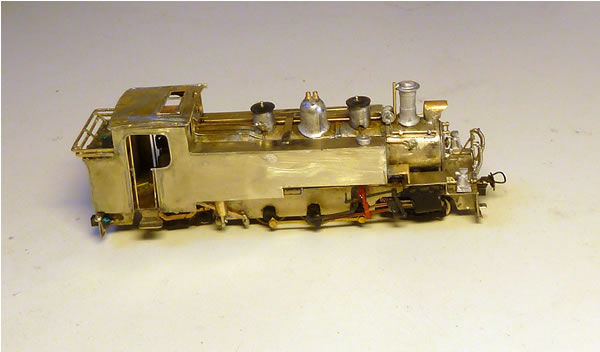

This Baltic was constructed in 6 days from scratch

Many etched brass kits are

available from small suppliers but few tackle the easy task of putting one

together. This is more so in the case of 009 narrow gauge modellers who more

often than not continue to exist in a world of plastic mediocrity. Back in

the days before electricity, an outfit called Rosebud Kitmaster brought out

a rather crude plastic kit of a Lancashire and Yorkshire Pug. 60 years

later, folks are still bashing them about to produce unconvincing facsimiles

of narrow gauge engines!

Also on the market are a

plethora of white metal kits. Most are crude and lack much detail. Most stop

at the running board and one must find an inappropriate chassis to stick

under it. A very small number do a worthwhile job and incorporate brass

etched parts as well as white metal. The Peckett produced by RM Models is a

good example.

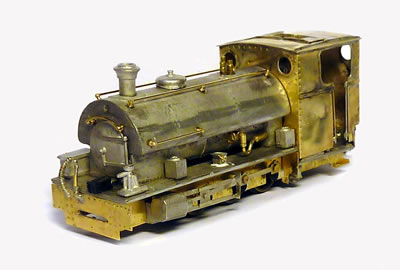

after two days of work, a fine loco based on the Grafar 08 chassis

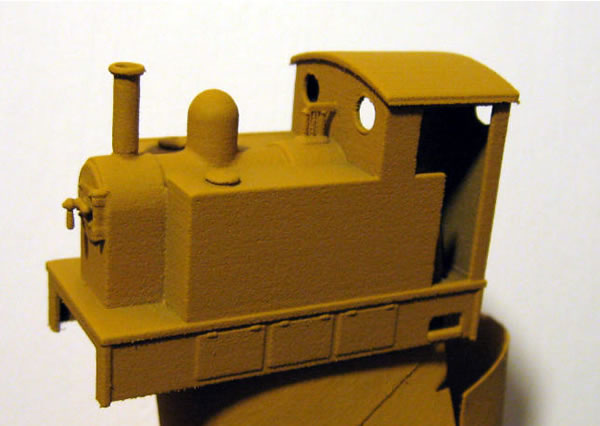

And now we find ourselves in

the era of 3D printing. While this might all be very clever, the spawn of

this technology is the release of dreadful looking toys covered in

corrugations which are almost impossible to remove.

Sadly, for many small scale

narrow gauge modellers, a lump of ugly plastic dumped on some antique

chassis, hidden by 'tram skirts' still appears to be the norm. In the

foreseeable future a ready to run Lynton and Barnstaple Manning Wardle, a

Minitrains Brigadelok, a Glyn Valley Tramway Beyer Peacock by Fourdees and a war department Baldwin 4-6-0 are to be

released. They will no doubt be of excellent quality and will eclipse the

usual rubbish locomotives founds on 009 layouts. Perhaps it will act

as a stimulus for building convincing models in this scale.

Somehow, though, I rather

doubt it. Apart from a few notable exceptions such as the Waller family and

Ted Polet, the best phrase to describe many adherents to this scale is 'they

are entirely satisfied with their own progress'.

the latest 3D printed offering! I rest my case

|