|

model railway wiring

Wiring worries many modellers but it only has

to be as complicated as you choose it to be and actually can be a

fascinating part of the hobby in itself. I shall not discuss sophisticated

systems as those who wish to go down that route will already have their

own ideas.

These days, one is frankly, in my opinion,

foolish not to elect to choose digital command control (DCC). This system

offers far better controllability and simplicity.

You will need a small soldering iron, stand

and thin resin core solder.

starter kit from EXPO

Tools

wire strippers and cutters

Small diameter heat shrink wire wrap, which

can be bought at shops like Maplins, and of course rolls of wire of the

required colours (five colours minimum). The wire should always be

multi-strand. Seven strand 0.2mm is nearly always sufficient.

You will also need a roll of self adhesive

copper tape for the under board bus bars and small cable ties. We have

found this method satisfactory for small simple wiring but on larger

more complex layouts, I now use N scale track glued on the underside of

the baseboard as a bus bar. It is far more robust and has less

resistance.

you can use these fellas

to screw to the underside of the baseboard

All the materials can be purchased from EXPO

Tools, All Components or similar supplier.

You should always solder electrical contacts.

making sure that a proper joint has been achieved. Try to keep the wiring

neat without too much excess of wire length. You can make up bundles which

are attached to the underside of the baseboard. Leave the cable ties loose

and thread through each wire until you have finished. You can then tension

the ties.

I am going to assume that the baseboard we

are describing is to be self contained. This will mean that various power

supplies have to be installed. These can be quite heavy so it really is

worth while making the rest of the model as light as possible. Provided

that the transformers are certified as double insulated, It is acceptable

to install under the baseboard provided that there is a reasonable passage

of air, for cooling. I tend to fix these things using cable ties.

1. If you are going DCC, you will

require a special power unit. It is foolish to use this transformer for

any other purpose. I no longer fit mains transformers in the baseboards

and prefer to leave them on the ground with a low voltage connecter to

the baseboard.

2. You may require another 12V DC power

source and even a 15V AC source as well, depending upon what ancillaries

you intend to install.

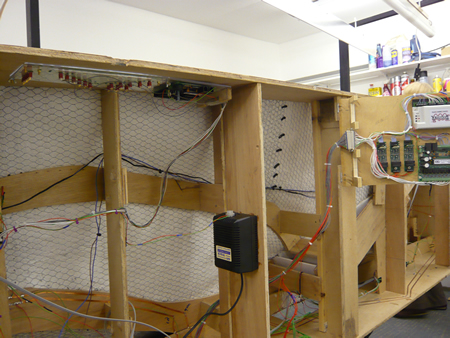

a transformer under one of our baseboards

- copper bus bars can be seen running along the framework We now place

transformers on the ground with a low voltage connecter to the board.

The mains wires from the transformers need to

be lead to a position on the baseboard where a socket is to be installed.

I use kettle plug sockets set into the baseboard side. The mains wire

junction is encased in silicone mastic and the rear of the socket

protected with a blue painted plywood cover (blue denotes mains wires). I

never lead the mains wires in the same bundle as low voltage wires.

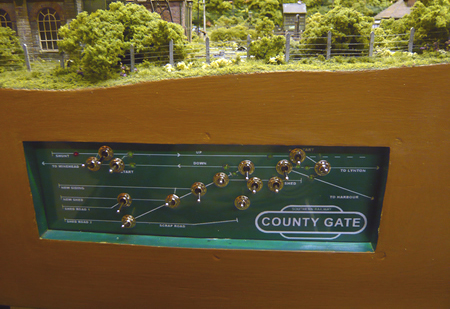

You will of course need a switch panel if you

wish to operate any points or signals. I make these from two sheets of

clear acrylic cut to shape. The graphics are generated on computer and

printed out. We use small double throw double pole switches supplied by

Expo Tools.

a switch panel on County Gate - This

panel has now been removed from CG.

You may elect to set your DCC controller into

the baseboard side as we have done. It is held in place by Velcro and

therefore easily removed. The wires entering into the controller are

easily unplugged.

This shot clearly shows how our Digitrax

Zephyr is set into the baseboard side.

We now have to fasten self adhesive copper

tape underneath to act as bus bars for the wiring. This is by far the

easiest method I know as it is so easy to solder on droppers from the

track and ancillaries. We source ours from

Expo Tools. For a

more robust solution, use N scale track as mentioned

above.

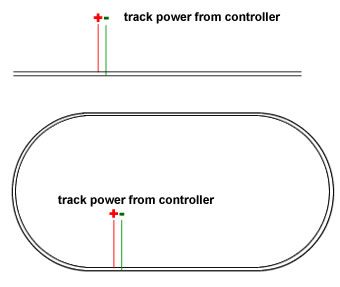

One pair of bus bars will supply track power.

You can then solder the red and green droppers from the track to the

requisite bars.

Make sure that you choose different colours

for your wires, say, red for positive and green for negative. If this

consistency in polarity is not maintained, you will have short circuits.

If positive rails are connected to negative rails, for example, nothing

will work, and even worse, your equipment might be damaged. In its

simplest form, wiring a track could not be more easy! The track power

supply

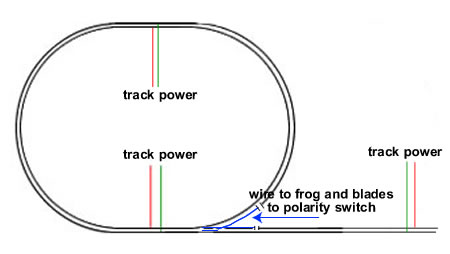

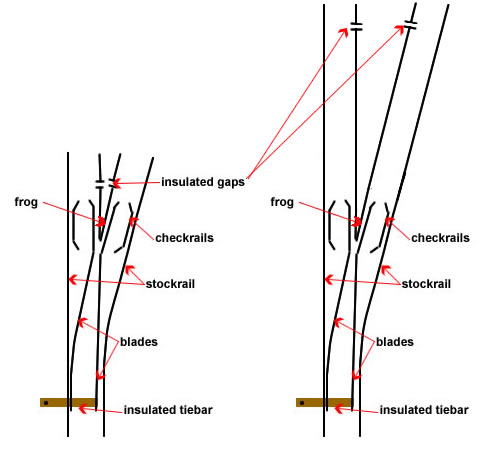

The problem arises once we add any points to

expand the layout. The frog (shown in blue) must change polarity. Track

power should be supplied to the rails every 600 mms from the under

baseboard bus bar in order to prevent voltage drop.

If you are purchasing ready made pointwork,

you will find that there are two kinds; live and insulating frog.

Insulating frog points should never be used so you are going to have to

change the polarity of the blades and frog when the point has its

direction changed or the blades will cause a short circuit in one

direction.

the dreadful Insulfrog

effort is the one at the bottom!

You will also have to install a point motor

under the baseboard in order to actuate the blades. This will allow you to

route trains remotely from your control panel. Some folks use mechanical

means to do this but frankly, I do not recommend it.

Unlike DC wiring, the track remains

live throughout at all times. The downside is that it is only too easy to

drive a train into a point that is set against it. This can be prevented

by extending the length of the isolated sections of the frog.

This is the simplicity of DCC as you no

longer have to worry about isolating sidings in order to stop the wrong

locos working as you choose the loco you wish to operate by selecting its

address. If the layout is already wired for DC, it will almost certainly

work for DCC as well, by the way. The only problem will be that you won't

be able to run another loco on one of the isolated track sections.

The only thing we have to do is to change the polarity of the frog

and blades when the running

direction is changed. This means that the frog must have insulated joints

to prevent a short circuit. Click on the switch below to animate.

DC

turnout

- click on switch to

operate

Despite many articles that describe 'DCC

Friendly' points, I do not bother to install them. If you are using Peco

'Crazy track', it would be very difficult to convert to 'DCC friendly'

anyway.

Just to explain what DCC friendly points are.

Some people are concerned that when running DCC which has a slightly

higher voltage (15VAC), a wheel might short circuit between the blade and

stock rail, so they add an additional rail break so the the blades are

always the same polarity as the adjacent stock rail. Indeed, learned

articles abound on the web about 'friendly' points. Again, click on the

switch to see operation. I find that it is quite unnecessary to go to all

this trouble and I think one is more likely to damage the very delicate

small points. A few locos or bogies may indeed touch the wrong polarity

blade and cause a short circuit. This is quite rare and the first thing to

do is to check the back to back measurements again. The worst offenders

are Riverossi power bogies which have flanges deep enough to cut into the

Earth's crust. The only solution is to give two coats of varnish to the

backs of the wheels (I use Ronseal). Once hardened, the problem has gone.

DCC 'friendly turnout' -

click on switch to operate

These days, I can only recommend point motors

supplied by Tortoise. They are adjustable and have

excellent polarity switches. The actuating wire is controlled by a motor,

so the point change is slow and silent and puts far less strain on the

point than the violent solenoid motor (Peco). The full PDF file for installation can be

found here. If there is a

depth problem under your baseboard, they can be fitted on their sides and

the actuating wire bent to suit. We find the wire supplied for the

actuator is too flexible to operate the blade springs on Peco points and

therefore use a slightly heavier wire. The connectors are simple to solder

to. I tend to glue the motors into position with 5 minute epoxy. To

ensure that they are correctly positioned, they are first wired up and

operated while the glue is setting, the motor being nudged one way or

another to get the best operation.

A Tortoise installed. The arrow points to

the throw adjuster which can be slid up or down to suit

The diagram below shows the wiring for two

point motors. The double pole, double throw (DPDT) switches would be

mounted in the control panel.

There are two single pole double throw (SPDT) switches

built into the Tortoise motor. One will be

required for changing the point frog polarity while the other can be used

for operating signals, etc. It is not always easy to work out which

terminals the track power should be connected to, so that the frog changes

to the correct polarity. I tend to do one at a time and test the

operation. If there is a short on track power, then reverse the red and

green wires!

The signals should also be connected at this

time. These may be interlocked with the Tortoise motors by leading wires

from terminals 5,6 and 7 to the signal motor.

|

Peco

motors, if you must! |

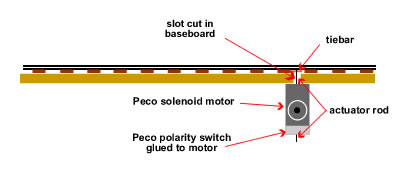

So lets look at the installation using Peco

point solenoids and polarity switch. Firstly, I solder a 'dropper' (a thin

length of wire) soldered on the underside of the frog. Once the exact

position of the point has been established, drill a hole in the baseboard

to allow the dropper to pass to the underside and drill a slot to give

adequate clearance for the actuating rod which passes through the hole in

the tiebar. The point is then fitted and fastened down (I just epoxy them

onto the baseboard). The fishplates are soldered to the adjacent rails but

do not forget to use insulating fishplates on both sides of the frog.

I then temporarily wire up the solenoid

including a switch and then epoxy the motor to the underside of the

baseboard. I make sure that the blades are held midway between the stock

rails and that the actuating rod is at the centre of the slot. As the glue

begins to go off, I operate the point and adjust if necessary to ensure

that there is an equal throw and that the blades go fully over.

Once the glue has gone off, I add the

polarity switch which I also glue on.

-

Make sure that the motor

is placed at the centre of the throw. If it is not, you will see the

actuating rod bounce back toward the centre. If this happens, the

polarity switch will not operate.

-

If you do have to remove

a glued solenoid motor, a couple of light taps with a chisel will release

it.

You are then ready for final wiring. The Peco

solenoid motor is operated through a Capacitor Discharge Unit (CDU). This

gives a good belt of electricity which powers the solenoid. CDUs are

powered from a 15V AC transformer. You must use a momentary contact switch

as holding power onto the solenoids will burn them out. Click on switch to

operate the image below.

Polarity

switches have not stood the test of time for both Peco and

Seep products. These days, I use Hex mono juicers and let

the electronics change frog polarity all on their own!

The Peco turnout maintains blade position by

a small spring hidden near the tie bar. These can fail and the system will

no longer properly hold the blades in place. If this happens, you can

replace the Peco motor with a latching Seep motor which is available from

Gaugemaster. The wiring is the same.

These days, if I must use solenoid motors, I

choose self latching Seep units. The spring in the Peco point is

removed. The advantage is that much less power is needed to throw the

point and it is less likely to eventually come to pieces.

The point motors can also be operated by DCC.

If this is done, each point will need a decoder which is not cheap. This

is done on County Gate because the operation is automated.

|

wiring slips, diamond crossings, three way points and

crossovers |

Wiring these

beasties for DCC is now a breeze. Just install a

Hex Frog Juicer and let it do all the work for you!

|

wiring slips the hard way (our thanks to Southern Digital) |

The information having to do with frog

polarity reversal is irrelevant to Peco InsulFrog turnouts. The

information about track connecting to the slip having the correct polarity

is applicable to any slip, no matter how itís made or who makes it.

A slip (single or double) has two frogs. For an ElectroFrog slip to work,

polarities must come to the slip correctly, and the frogs needs to have

individual polarity reversing capability. In most cases itís all fairly

easy to do - especially with DCC. There are four wires coming from the

bottom side of the double slip - one from each frog. The wires are

imbedded in grooves in the ties.

A slip, single or double, requires certain things for it to work. This

includes polarities being correct, and a way to reverse the polarities of

the frogs when needed. Whether itís a single or double slip is irrelevant

when it comes to polarities. They are both installed and handled in the

exact same way. The only difference is that there is only one slip to

allow transition from one route to the other. Regardless, both frogs and

all routes have to be considered. Weíll first show how a double slip needs

to be installed, then explain how to deal with polarities.

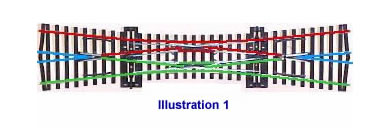

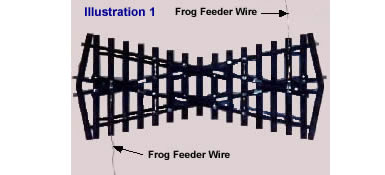

Illustration 1 shows the rails that are fed by each feeder wire. The two

blue frogs are separate, each with its own feeder. The red indicates the

rails that are fed by the feeder going to the top stock rail, while the

green shows the rails fed by the bottom stock rail feeder. The frog feeder

wires must be used to control the frog polarity, and insulated rail

joiners must be used to connect the adjoining rail to them.

The stock rail feeders can be used to power

the stock rails, or the stock rails can be connected directly to the

adjoining rails with metal rail joiners. There are four wires (feeders)

coming from the Peco ElectroFrog Slip: one from each frog, and one from

each stock rail.

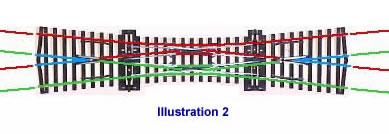

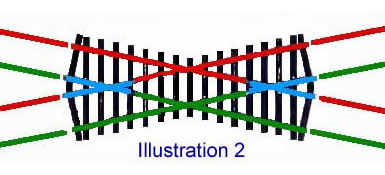

Illustration 2 shows that the polarity of the

rails joining to the slip must match the polarity of the slipís stock

rails.

You can see that this will be connecting both

polarities to each frog, which is why those rails must be connected with

insulated rail joiners.

If using DCC, there are two ways to control the polarities of these frogs:

auto-reversing, or external contacts connected to each throw bar.

If using auto-reversing, you can use two Digitrax Auto-Reversers (D-AR1)

or two of the four outputs of a Digitrax PM-42 (D-PM42). If using the

D-AR1, connect one output of one D-AR1 to one frog, and one output of the

second D-AR1 to the other frog. If using a PM42, connect one wire of one

output to one frog, and one wire from the second output to the other frog.

It doesnít matter which output wire you use, as long as you use a separate

auto-reverser for each frog. In any case, it will auto-reverse when a

short circuit is sensed at either frog.

If using external contacts, you have to realize that the throw bar on one

end of the slip needs to control the frog on the other end of the slip.

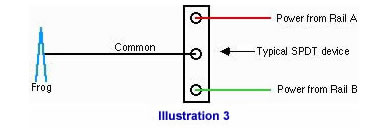

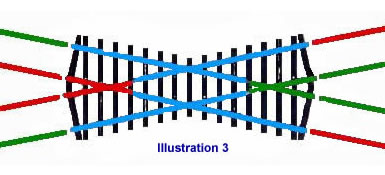

Illustration 3 shows how to do that.

This could be Peco contacts mounted on a Peco

switch motor, a SPDT micro switch mounted to make contact with the throw

bar, or any other common Single Pole Double Throw (SPDT) device. When the

throw bar is one way, it feeds power from Rail A,; when set the other way

it feeds power from Rail B.

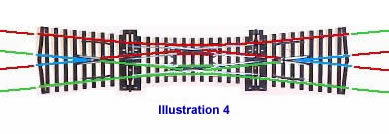

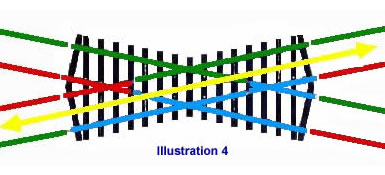

Illustration 4 shows a situation that will

have to be corrected before you can make the slip work correctly.

Notice that the track coming into the double

slip from the upper right doesnít have the correct polarity. This means

that you have a reverse section somewhere on the layout that hasnít been

resolved, and will not work. To fix this, you need to go back on that rail

and install a reverse section so that the polarity comes into the slip

correctly.

There are many variations of this, but regardless of what the situation

is, the polarity must match as shown in Illustration 2 above. Note that it

doesnít matter what the polarity is as long as it matches in all

directions. Once it matches, resolve the frog polarity as described above.

Again, with Peco InsulFrog Slips, you do not have to be concerned about

reversing the polarity of the frogs. But you do have to be sure the

polarity of tracks attached to the slip is correct.

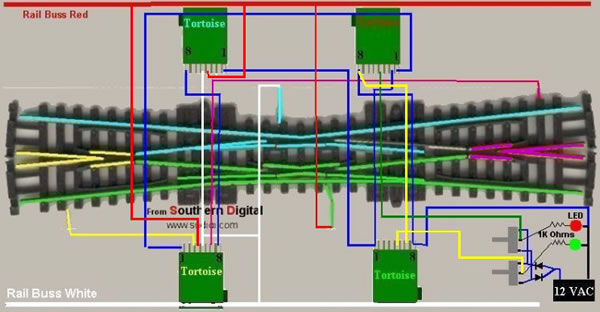

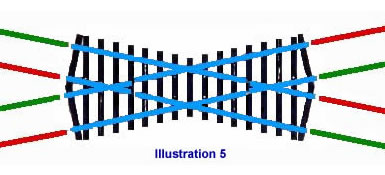

Illustration 5 shows you how to wire your double slip switch using

Tortoise contacts to route the power to the rails properly and adding LED

indicators.

|

wiring diamond crossings the hard way |

The information having to do with frog and

crossover polarity reversal is irrelevant to Peco InsulFrog crossings. The

information about track connecting to the crossing with the correct

polarity is applicable all crossings, no matter how itís made or who makes

it.

A crossing has two frogs. How the polarity comes into the crossing will

determine whether the frog or the rest of the crossing needs to flip

polarity. Regardless, in most cases itís easy to do ó especially with DCc.

As you can see in Illustration 1, there are

two wires coming from the bottom side of the crossing; one from each frog.

The wires are imbedded in groves in the ties. If youíre running DCC you

can use a Digitrax Auto Reverser or one output of a Digitrax PM42. Thatís

what the rest of this dialog will address. If using DC analogue control,

youíll have to handle it in the traditional way ó with toggle switches.

The first of four situations is where the

polarity comes into both ends of the crossing with opposite polarities to

the frogs, as shown in Illustration 2 at right.

Notice the rails that connect to the

crossingís stock rails are of the same polarity. But the rails that

connect to the frog rails (blue) are two different polarity. This is the

easiest situation to handle. Simply connect one frog to one output of the

auto-reverser, and the other frog to the other output of the

auto-reverser. Be sure to use insulated rail joiners on all four frog

rails. You can use metal rail joiners on the stock rails.

The next situation, shown in Illustration 3,

is where the polarity comes into both ends of the stock rails with

opposite polarities. In this case, the stock rails become the reverse

section. Connect the frogs with metal rail joiners, connect the stock

rails with insulated rail joiners, connect one output of the auto-reverser

to one stock rail (blue), and the other output of the auto-reverser to the

other stock rail (blue).

The third situation, shown in Illustration 4,

is more complex. It involves coming into one end of the crossing with like

frog rails and the other end with like stock rails. Thatís because you

have a reverse section somewhere on the layout that hasnít been taken care

of.

Since there are two blue (reverse) sections,

one might quickly think that all that needs to be done is to connect each

one to an auto-reverser. But notice when travelling the yellow route that

the polarity changes from one side of the crossing to the other. While the

frog rail could change to red without any problem, the stock rail canít be

red and green at the same time. Even if it could, when a loco spans the

crossing from one connecting track to the other, it would cause a short

circuit.

In this particular situation you need to take care of the reverse section

needs elsewhere to make the track polarity come into the crossing to match

one of the previous two examples. Taking care of the reverse section on

the lower left track would create a situation like in Illustration 2 ó

preferable. Taking care of the reverse section on the upper right track

would create a situation like in Illustration 3 ó not preferable, but

easily handleable.

The fourth situation, shown in Illustration 5, is similar to the last one,

in that there are reverse sections elsewhere on the layout that havenít

been taken care of.

Notice that the difference between this and

the last situation is that no matter which route you take, the polarity

reverses on the other side. This means that more than likely you have two

reverse sections to fix elsewhere on the layout. To make handling the

crossover polarities as easy as possible, itís best to take care of both

reverse section needs from the same end of the crossover. Doing this will

make the stock rail polarities the same, and leave only the frogs to make

reversible (with insulated rail joiners).

Again, polarity reversal is not applicable to Peco InsulFrog crossings,

only to live frog crossings.

|

wiring three way points the hard way |

3-way ElectroFrog turnouts have a unique need

for controlling frog polarities.

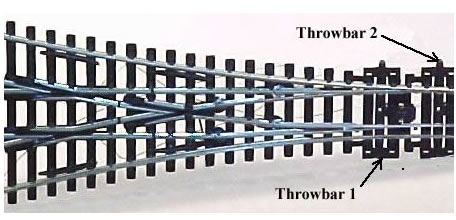

As you can see with the photo above, there

are three frogs: one right in the middle, and one on each rail of the

middle route. With Peco ElectroFrog 3-ways, the upper frog and the frog in

the middle are connected together to one feeder wire. The lower frog has a

feeder wire of its own. You can also see that there are two throw bars.

Weíll call the throw bar closest to the end #2, and the other one #1. So,

with just two feeders and two throw bars, how do you control the polarity

of three frogs? Simple. Since only two frogs are used at one time, there

is always one frog that is not used ó no matter how the throw bars are

set. Check the illustrations below to see how polarities work with the

various settings.

|

|

|

|

|

|

Train

|

Going left

|

Going straight

|

Going right

|

|

Left frog

|

Red

|

Green

|

Irrelevant

|

|

Centre frog

|

Red

|

Irrelevant

|

Green

|

|

Right frog

|

Irrelevant

|

Red

|

Green

|

|

Throw bar #1

|

Right

|

Left

|

Left

|

|

Throw bar #2

|

Right

|

Right

|

Left

|

In Illustration 1, both throw bars are to the

right, making the train go left. You can see that the left and centre

frogs are both of the red polarity. In this situation, the polarity of the

right frog is irrelevant.

In Illustration 2, throw bar #1 is to the left and throw bar #2 is to the

right, making the train go straight. You can see that the left frog has

green polarity and the right frog has red polarity. In this situation, the

polarity of the centre frog is irrelevant.

In Illustration 3, both throw bars are to the left, making the train go

right. You can see that the centre and right frogs are both of the green

polarity. In this situation, the polarity of the left frog is irrelevant.

At no time do the centre and right frog have to have different polarities.

They are either of the same polarity (Illustration 3) , or one or the

other is irrelevant. This is how the right and middle frogs can be tied

together to have the same polarity. So, all we have to do is figure out

how to control the frog polarities with the two throw bars.

By using a set of Single Pole Double Throw (SPDT) contacts on the switch

motor, or a micro switch on throw bar #2 (the bottom one), we can control

the middle and right frogs. When throw bar #2 is to the left, it will feed

green polarity to those frogs so the train can go to the right. When throw

bar #2 is to the right, it will feed red polarity to those frogs so the

train can go straight or to the left.

By putting a set of Single Pole Double Throw (SPDT) contacts on throw bar

#1 (the upper one), we can control the left frog. When throw bar #1 is to

the right, it feeds red polarity to the left frog so the train can go to

the left. With throw bar #1 to the left it feeds green polarity to the

left frog so the train can go straight. If the train goes right, the left

frog is not used, so it is irrelevant.

Wiring on model railways can get very

complicated very quickly. It is most important to keep track by drawing

out good wiring diagrams. I have always done this by computer and posted

them on my website so that they can be easily accessed if we are away on

exhibition.

see here

So after all of that, you should have a

baseboard with operating points, frogs which have the correct polarity,

signals that work and track power from your controller throughout. There

are of course other things which you may wish to install at this time such

as our 'wobbler

system' or some form of electric uncoupling system. Once you are happy

with it all, it is time to turn over the baseboard and check that it all

works correctly.

Start running train around and hopefully you

will have to make few adjustments to ensure that operation is perfect.

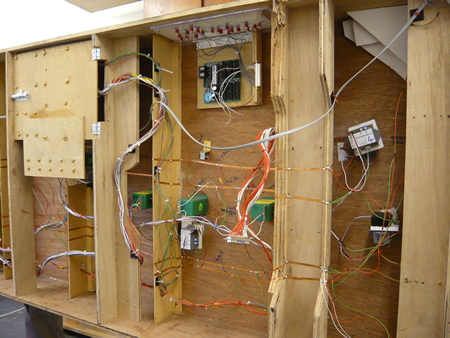

a baseboard with wiring complete - point and signal motors can be seen as

can the copper bus bars

|