|

wheels, flanges and back to backs

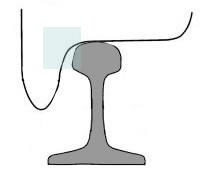

Wheels of railways are a great deal more

complex than first meets the eye. The angles of the tread and the radius

between the flange and the tread (blue area) are very carefully worked out

to minimise friction and wear. Full size railways even use different

materials for parts of the wheel profile. At regular intervals the wheels

are built up again with weld and ground down to specification.

When model railways first began to become

popular, no one cared very much about accurate rendition and concern was

that the train stayed on the tracks. Wheel profiles could be described as

'agricultural'.

Many model railway manufacturers, have over

the years developed their own standards and for a period of time, 00 scale

trains could not properly run together. It was an excellent way to force

customers to remain loyal to Hornby, Trix or Triang, I suppose. The

problem was solved by Wren 'universal two or three rail track' by

developing points that did not operate like the real thing at all.

Gradually, due to company takeovers, some

standards became established in OO scale. Sadly, the scale included track

was was a scale several inches too narrow. The Europeans from the start

elected to build models in H0, which rendered the track gauge of 16.5mm

correct. Nevertheless, they took a long time to standardise wheel,

coupling and track standards. The whole sorry story of 00 is proof to me

why Britain will always be a reluctant member of the EEC.

Things improved with the introduction of Peco

track and even a chaired track system became available from Chairway.

Gradually, serious modellers in Britain have

established more scale track gauges. EM gauge, (18mm gauge) and

subsequently scales like protofour, (18.83mm). This is fine scale.

In these new scales, flange depths have been

reduced to scale and for the first time in the UK, model 4mm/ft trains

look right.

Most 4mm/ft modellers still use the 00 narrow

gauge track and run their trains with deeper flanges than scale and

heavier rail. This is course scale.

Similar differences exist between fine and

course scales in gauge 0, 1 and upwards.

Points are now built as in prototype

practice. As the frog is fixed, outer check rails are needed to

guide the wheels and prevent them hitting the point of the frog which will

result in a derailment. The means that the gap between the stock rail and

the check rail have to be specified and accurate. Likewise, the back to

back measurements of the railway wheels have to be accurately set. Below

are shown the dimensions for fine scale 00 gauge. Back to back

measurements must be checked for all wheels. A gauge can be purchased for

most scales.

Some commercial points, such as those of

Peco, have the frog set in plastic so when a wheel cross the gap at the

frog, the flange is supported. Sadly, wheels do not all have flanges set

to a standard depth and some, such as Riverossi N scale, have such deep

flanges that they will jump at the frog. It is then necessary to excavate

the plastic to allow the wheel to cross freely (or throw the Riverossi

away).

|

4mm

two foot narrow gauge |

Early narrow gauge modellers had it all

to do themselves. For those modelling 2ft gauge railways, a track gauge of

8mm was sensibly chosen. From the Hatfield, UK, came a company called Lone

Star. They built die cast toys including things such as cap pistols. A

range of push-along trains were released with a track gauge of 8mm.

Eventually these were motorised and a new gauge of 9mm was selected. It

was called 000 which was the start of the popular N scale.

These days, most of use who model in narrow

gauge, employ the N scale gauge as standard although a few people do model

in fine scale and 8mm gauge.

Models of three foot/metre gauge railways

used TT scale track, (12mm gauge).

There is a standard for N gauge which is

relatively fine scale. It was set by the NMRA (National Model Railroad

Association).

| Norm/standard |

Gmin

Gmax |

Cmin

- |

-

Smax |

-

Fmax |

Hmin

- |

-

Pmax |

| NMRA S-3.2 |

8.97

9.32 |

8.20

- |

-

7.52 |

-

0.76 |

0.56

- |

-

7.92/8.05 *) |

| Norm/standard |

-

Kmax |

Bmin

- |

Nmin

- |

Tmin

Tmax |

-

Dmax |

P

- |

| NMRA S-4.2, RP25 |

-

8.20 |

7.54

- |

1.80

- |

-

0.51 |

-

0.56 **) |

0.18

- |

| Norm/standard |

N' |

T |

W |

D' |

P |

R1 |

R2 |

R3 |

| NMRA RP25 |

1.83 |

0.51 |

1.32 |

0.51 |

0.18 |

0.20 |

0.23 |

0.23 |

Rather sadly, this

standard did not really travel well to Europe and there is still a

ghastly profusion of course wheel standards out there. So those working

in H0e and 009 are left with having to fiddle around with our pointwork

to find some happy compromise, unless we are absolutely brutal and insist

on one wheel standard. Sadly, this is not always possible for those of

use who have large collections of stock. Peco track seems to have found

some reasonable compromise although the crazy track points should be

avoided at all costs.

early Minitrix pizza cutter flanges

|