|

the viaduct step by step

While much of this information is also copied

elsewhere, we thought it might be useful to show how this module was built

step by step.

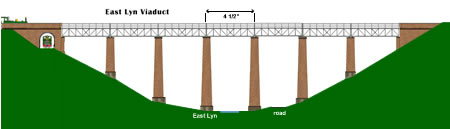

projected viaduct design -

click to enlarge

'River Avon' hauls a goods to

Lynton

over the newly completed viaduct section

- click to enlarge

click to enlarge

|

the

build - using Wills plastic building sheet |

We have spent a great deal of time discussing

the design of the viaduct as it is such an important element of the County

Gate layout. Finally, we decided that we did not want to have a 'Chelfham

structure' as this had been modelled so often already. The

open structure of the lattice girders will allow the trains to be much

better seen and the girder lattice has very good visual impact. We

want the trains to 'teeter' across it! A deceleration circuit will be put

in place on the viaduct.

I am fortunate in having a civil engineer son

who did rough calculations to confirm that the full sized structure would be safe

and an appropriate design of the period for

the prototype loads.

The plastic building sheets produced by Wills

are a fantastic aid to scratch building. Some special techniques are

needed to make sure the resource is best used.

-

The material is slippery

and it is very hard to hold a steel rule in place while cutting. We use a

steel rule that has has fine sandpaper glued to one side. This stops

those embarrassing errors with the knife.

-

It is important to use

sharp cutting blades. They become blunt quite quickly when hacking at

this hard material. As the point loses the edge, we break off the tip to

expose a new cutting edge.

-

When cutting a sheet, two

passes of the blade is usually sufficient to score the plastic enough to

be then able to snap off the part by bending.

-

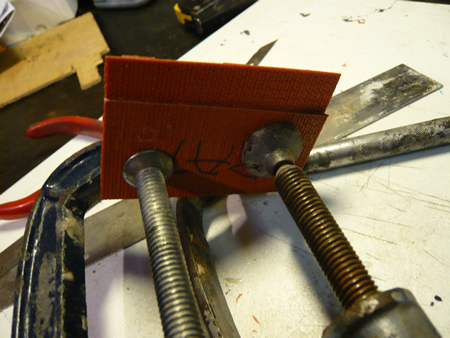

When making the viaduct,

we had many surfaces to cut which were at an angle. We used one sheet of

plastic as a pattern, and cramped it on to the sheet to be cut to prevent

any slippage.

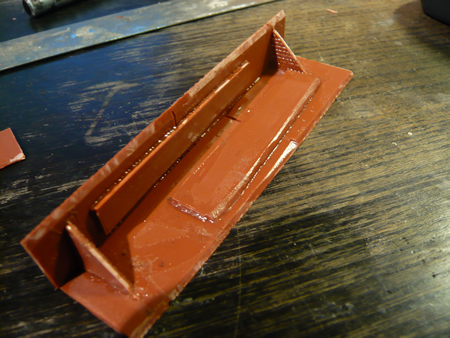

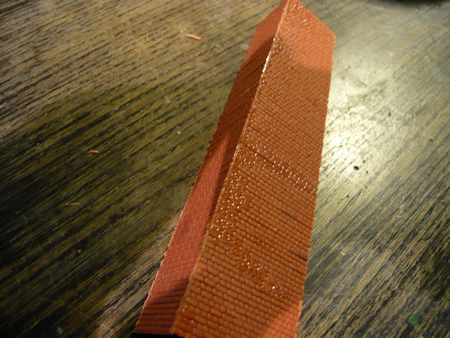

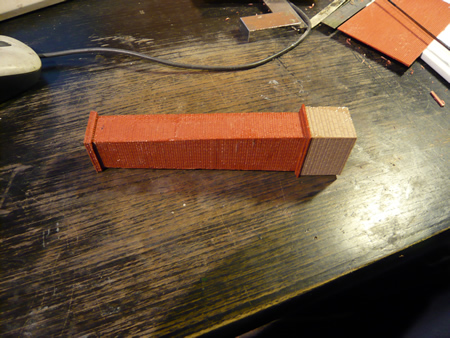

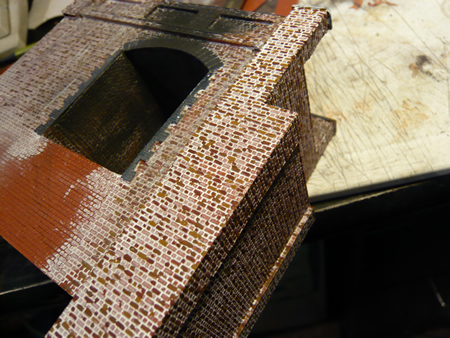

These are the underside of the viaduct piers. The mitring is clearly seen

the but joints are

reinforced using off cuts. While the glue is still slightly soft, make

sure that the face surfaces are accurately in line.

-

When gluing, coat both

mating surfaces a couple of times, then run more Plastic Weld into the

joint from behind. It is important that glue does not migrate to the face

as detail will be lost. After a few minutes, the plastic is sufficiently

soft to be able to gently 'wiggle' both surfaces together so that any

irregularities are filled by molten plastic. Make sure that brick

courses, etc., are in line. We often add triangular bracing pieces to

strengthen the joint.

construction of viaduct

piers

Here, the final side has

been added. The mating surfaces still need to be nudged closer together

while the plastic is still soft

-

When the joint has fused,

but is still very slightly soft, we run a sharp blade across the corner

to remove any excess plastic. The brick joints are then extended round

the corner using a lightly applied blade which is rocked side to side to

expand the joint to the correct width.

the completed pier

-

Observe with care

bricklaying techniques used on the prototype. Fancy brick courses can

easily be cut from the sheet. If you wish to have curved bricks, the

profile can be sanded and the brick courses added with the craft knife.

-

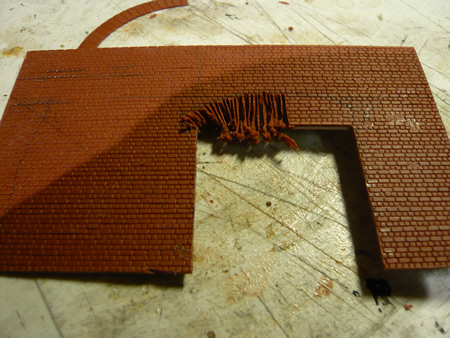

We prefer to build Wills

arches flush into the sheet. This means accurately cutting the sheet. For

this we use a Dremel cutting disc. The final fit is done with careful

paring with a knife.

The bridge for the

harbour branch under the South abutment.

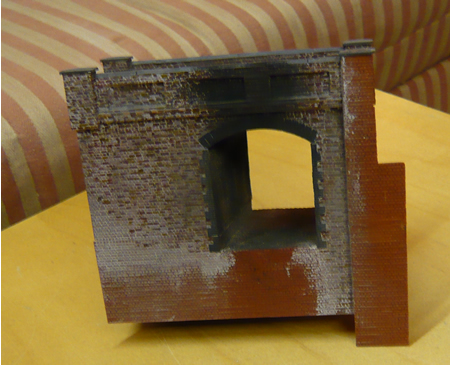

Partially complete South

abutment

Brickwork picked out with

three colours.

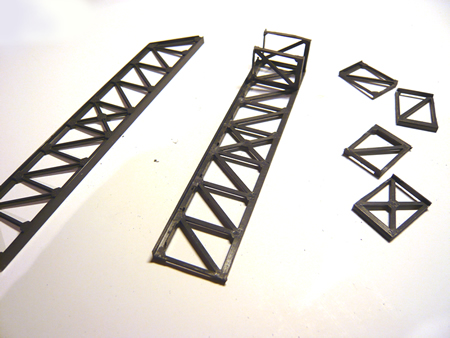

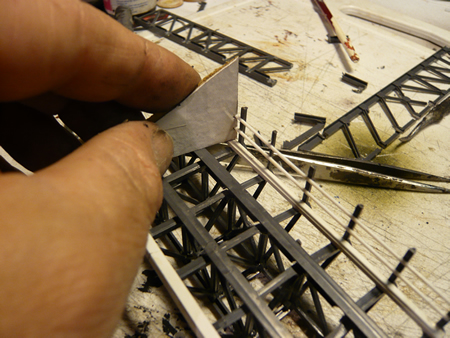

The trusses are made from

Peco N scale girder bridges. 2 packs are needed for each truss, (8 sides)

the trimmed truss

sections - click on image to enlarge

cross members are

fabricated from other trusses

- click on image to enlarge

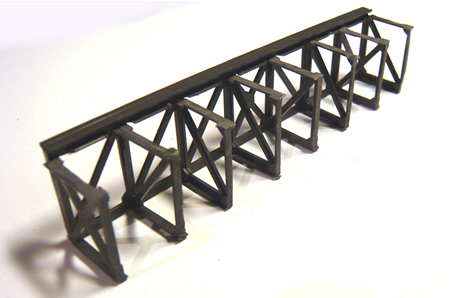

Once the truss is

fabricated, the foot walk canter levers are cut from spare trusses. Each

end is first fitted and joined with the 'timber balk' and the others are

fitted afterwards. Care is need to ensure all is square.

Handrail stanchions are

also made from parts of the spare trusses and the rails attached using the

jig shown above.

- click on

image to enlarge

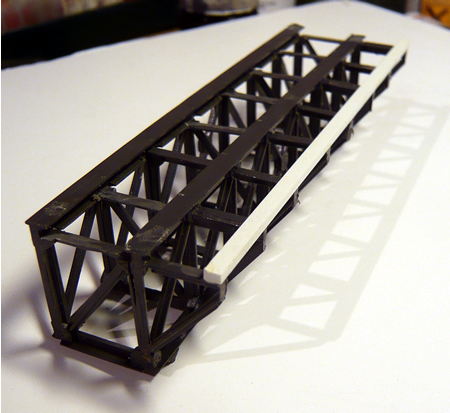

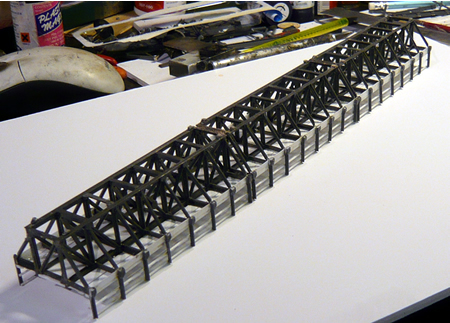

All the spans can be

glued together making sure they are straight and in line.

- click on image to enlarge

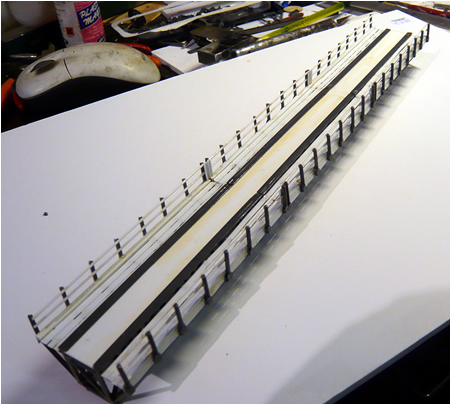

The deck is then added

and the 'timber' walk way planking

- click on image to

enlarge

The viaduct is assembled on the plywood

base. Care must be taken to ensure the piers remain on centreline and are

vertical.

The 44" long, completed viaduct is now ready for installation. The road

and river bed can also be seen. The valley profile was built using foam

board covered in Modrock

|