|

laying the track

Early railways used chaired track. These

included the Festiniog, Penrhyn and Padarn Railway. Flat bottom rail

quickly became the norm for all subsequent lines.

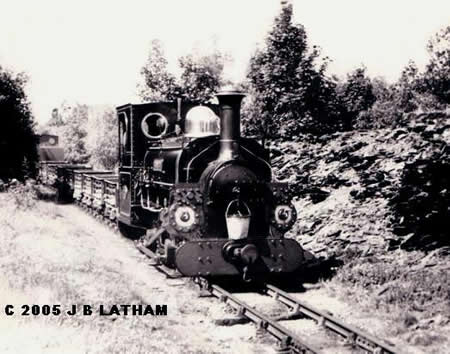

the Penrhyn Railway

Generally, narrow gauge track was quite

lightweight. The Lynton and Barnstaple Railway, for instance, was laid in

40 lb rail.

Lyn on the L&B

This meant that axle loads had to be

relatively light to prevent damage. Modern railways such as the new Welsh

Highland use rail almost double in weight. This can highlight the

narrowness of the track.

a cold day on the new WHR - photo by David

Firth

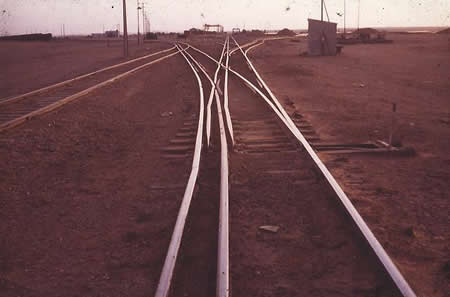

some railways have sections of dual gauge

track

These days, it is possible to hand build

accurate model track. Most of us still purchase ready made products.

hand built narrow gauge track by John

Clutterbuck

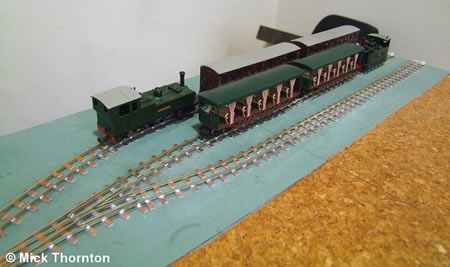

hand built 009 track by Lynne Grant -

photo Mick Thornton

The number one rule is to make absolutely

sure that your trackwork is as near to perfect as you can make it. Once

scenery has been added, it becomes very difficult indeed to put things

right. The next rule is to have curves as easy as you can possibly make

them and try to avoid double reverse curves.

Your locomotive may officially go round a 12"

radius point but will they do so smoothly without buffer or coupling lock

when pulling a train. If you ever intend to propel a train, the track has

to be even better. Always select live frog points.

Wherever possible, use transitional curves.

These are curves that gradually decrease in radius and you move towards

the curve apex.

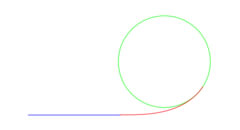

The drawing above shows a transitional curve

(red) of track entering a spiral of fixed radius.

If you have used a track design software

programme, you will have the facility to print out the result full scale

and lay this down on your trackbed. This will make life a bit easier but in

the end, a good eye for setting down track is as good as anything. Often,

I will lay out track and lineside buildings on a wooden floor covered with

inexpensive brown paper from a roll used for masking off cars in paint shops and jiggle about with

them until I am happy with the result.

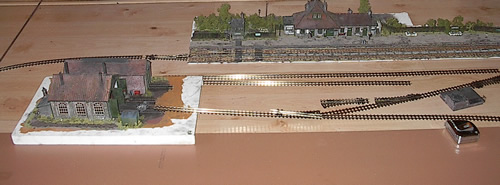

the start of laying

out of County Gate station

Once you are happy with the layout, you can

begin to transfer the information to the trackbed. I always suggest that

you select good quality 3 or 4mm ply for this purpose. This can be cut to

size and attached to the baseboard.

a complicated trackbed by

PLS baseboards

Model trains can climb gradients better than

the prototypes but I suggest that you keep the grades as gentle as

possible. If you are unsure, set up a section of track to your required

grade and try running a heavy train up it.

Some will require the track to be laid

slightly higher to represent modern trackbed. If this is required, you

will have to carefully cut an additional layer of thin ply which should be

firmly attached.

You may have to cut into the trackbed where

you have say, an inspection pit. It is best to complete and detail the pit

at this time.

track

You may decide to purchase ready made track

such as the products supplied by Peco or you may 'bite the bullet' and

build your own. A first class complete system for building your own track

is supplied by US company

Fast Tracks. Their website is first

class so it is really worth taking a look.

If using ready made track, choose the largest radius

points that you can fit into your plan. For 009, a new range called Peco

Mainline have points with an 18" radius. Their design is vastly

improved compared with previous 'Crazy Track' incarnations which I cannot recommend

being not very reliable and very rough running, apart from being only

12" radius.

Set track systems are also on sale. I suggest

that they are left in the nursery room where they belong.

Other points are available from manufacturers

such as Tillig.

Those who build their own track really do not need to

bother with the following section.

I tend to place pointwork in their

approximate position first and then lay track between. To cut track, use

either a Dremel cutoff disc and ensure that the end is smoothed to allow

the installation of a fishplate. I always start in areas where there are

points and add the long lengths of track afterwards. Keep the connected

track in smaller sections as it will have to be handled. Do not forget to

ensure that parallel tracks afford sufficient clearance for trains. I have

once forgotten about duckouts on brake coaches!

the start of track laying

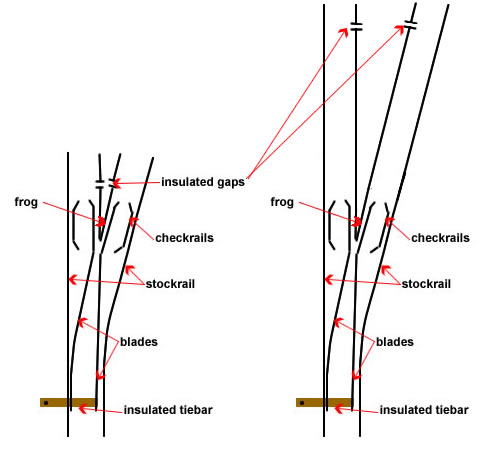

Gradually, you will be able to connect the

track together as you require. Once happy with the result, the next job is

to solder the rail joints, an essential step to ensure good continuity. Do

not forget to use insulating fishplates at point frogs. You may consider

building in the break a little further away from the frog. This could very

well prevent collisions if you are using DCC.

preferred remote insulated rail joints

shown on the right image

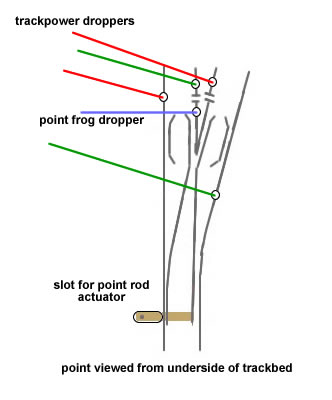

Once you have connected and soldered your

track section, it is time to add wiring. Carefully turn over your section

of track. The point frog will have to change polarity when the point

switches so it will require its own power supply which will be connected

to a bipole switch. I always use thin white wire for this application. Use

a short length, say 12" and solder one end to the underside of the frog.

You will also have to lead power to the main running rails at regular

intervals of about 24". Again, always make sure that you use two colours,

say red and green, and do not mix up polarities. I

always use red wire for the rail next to the backdrop and green towards

the front of the layout. Again, solder lengths to the underside of the

rails.

Once complete, turn the track over again and

place it in the correct position and mark the plywood where the wire

droppers are located. Push the track over to one side and drill the

plywood trackbed with a small clearance hole to accommodate the wires.

Feed the wires through the holes and check that the track is in the

correct position. There have been times when I have had to redrill holes

until I am satisfied with positioning. Hold the track section down in its

correct position with Gaffer tape and using a propelling pencil, place it

through the tiebar actuating hole and operate the point side to side.

This will leave a line which must now be

opened with a small drill into a slot. Make the slot a tad longer at each

end to avoid binding.

Once you have completed the section with

points, you can now attach it to the baseboard. Mix up some 20 minute

epoxy and place blobs at the end of sufficient sleepers to firmly attach

the track. Make sure that the sleepers either side of the point tie bars

are very firmly fixed indeed.

As the glue begins to thicken, this is the

time for any last minute positioning adjustments. Eye the track at low

level down the rail and you will easily see any wobbles which can easily

be removed.

I always make sure that the track is

completely flat onto the trackbed by placing a small sheet of MDF (as flat

as you will get) onto the track and weighting it down until the glue has

cured. Ensure that no glue has migrated onto the tiebar. This can be

cleared off if necessary if the glue is still slightly soft.

tracklaying on the fiddle yard

You can now attach the flexitrack remembering

to include track power droppers. If you require a block section for any

reason, do not forget that they should have their own power feeds. Use

different colours of wire. Most block sections only require one rail to be

isolated. Where track is to pass from one baseboard to the next, terminate

the track about three inches from the end.

Fill the gaps between insulated rail gaps

with a little epoxy. This will prevent rail movement and shorting in hot

weather.

Model rail will expand and contract just like

the real thing. Once you have laid all of the track, it is really worth

while heat soaking it. I just bang on a couple of fan heaters until the

room is unbearable and leave for an hour. You may find you get local

problems that will have to be rectified. Some exhibition halls can become

unbearably hot and you really do not want to find such problems in these

circumstances. When the layout, on the other hand has become extremely

cold, some joints may also fracture. This is of course much harder to

check for.

Where track goes from one baseboard to the

next, fit the baseboards

together and we lay track across the joint. Leave an expansion gap or

0.5mm when joining to the laid track and do not solder the fishplates

here. You will therefore have to provide this short section with its own

track power feeds for reliability's sake.

The final track section should be set in

solid epoxy glue to prevent any movement at all. Some chose to solder the

rail ends to pins or copper clad as well. Once the glue has cured, you can

cut the track at the baseboard joint with a fine saw.

The most important issue is to ensure that

the track is as near as possible at right angles to the baseboard joins.

Oblique angles will cause nothing but problems. You may have to modify the

baseboards so that the joint is actually at right angles.

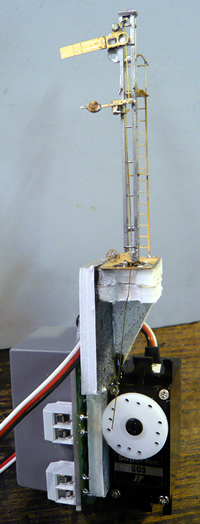

It is now the time to install any working

signals. These will have motor actuation from below. Although expensive, I

use signals provided by Model Signal Engineering (Wizard Models) along

with their 'bouncy' actuators.

after painting, this signal is ready for

installation

|