|

A simple method to make class 08 steam chassis

A new series of

Glenthorne locomotives have been described here using heavily modified

Bachmann 08 diesel chassis. Finally it was possible to build 8 coupled

locomotives but such work requires the complete dismantling of the

chassis which is extremely hard to get back to work well.

I was asked to develop the most simple

way to add valve gear to such a chassis.

I now always use ROCO valve gear which

can be ordered from Gaugemaster. There are two types.

- Roco 122875 from model HOe OBB 399.

This has two slidebars

- Roco 116295 which has a single

slide bar.

Parts are NOT interchangeable.

The first example uses

Roco 122875. The connecting rod may be attached to either the rear wheel

set or the centre one (preferable as this is the driven set). In this

case the rear driver was chosen as I wish to build a shorter locomotive

more suitable for Cliffhanger. If the centre driver is to be used, the

outer chassis frame will need to be extended using thick Plasticard.

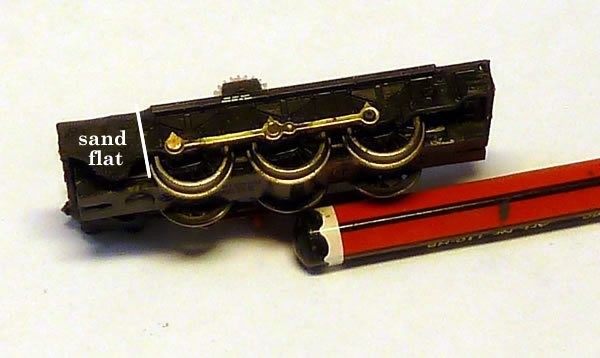

Remove the body of the

locomotive and sand flat the frames just forward of the front spring

hanger.

The motor can be removed by prizing open

one of the locking tabs using a pointed blade from below. It is not

necessary to remove the brake rigging although the photo above shows

them missing. The four small holes previously used for attaching the

body should be drilled out to give clearance for 12 BA screws.

The valve gear needs to be divided into two

sections. For this, it is important to lock all the parts of the gear

together with epoxy glue as shown here. I also drop a small amount of

thick superglue to lock the slidebars into the support. They come as

push fit only.

Cut the red slide bar support as shown in

photo. I use a fine toothed cutting disc for this.

Also cut back the rear of the two cylinder

blocks.

The cranks which will receive the

connecting rods and eccentric cranks need to be opened up so the cranks

will push fit into them.

Scrape off the paint on the coupling rods

and pins and remove the pins where the connecting rod is to be fitted.

Fit the connecting rod on one side using

the return crank. The spigot is delicate and easily broken. Ensure the

hole is large enough to allow an easy push fit. Cut the spigot flush at

the back of the crank.

Now glue the cylinder in the required

position making sure that there is full movement of the crosshead and

the the return crank. The cylinder may be attached level or angled

'according to taste'. Ensure that there are no binds or contact points

while the glue dries. Repeat for the other side. You should now have a

free running perfect chassis. Attach the return cranks with thick

superglue from the rear and glue the slide bar supports to the chassis

with epoxy.

If you are using DCC, remove the spigot on

the chassis which hold the phosphor bronze tag onto the motor and then

replace the motor and check for operation.

|