|

Building the Glenthorne Harbour

Baldwin No2

As the harbour traffic increased, it became

clear that more powerful motive power was needed. In 1906, they purchased

from Baldwin, USA, at very good terms, a 2-6-2 tender locomotive which became the only locomotive

to carry a name; 'Ben Halliday' ..............

This project began when Victors Scale Models announced their intention to release an etched

brass kit for Sandy River and Rangeley Lakes Baldwin No 19. The principle

data is written below.

The kit was dispatched 9th Dec 2008 and

arrived two days later. Sadly, Victors are no more but one hopes that the

kits will be re-introduced.

Built: 1904

Cylinders: 12" x 16"

Driving wheels: 33"

Total weight: 50,000lbs

Tractive force: 10,682lbs

Tank capacity: 1,500 gallons

Formerly: No.8 of the SRRR

Scrapped: 1935

Instructions for the build of this loco can

be downloaded as PDF files here

photos,

text

motor installation

The first part of this odyssey uses the

photographs supplied in the PDF files as Jenny was on a cruise and

had the camera. The kit arrives in a nice deep plastic box which serves

well to keep all the little bits in during construction. At £160, the kit

is quite expensive (double that of my Backwoods jobs) so it does have to

be good. The first dilemma was whether to out shop the chassis or not. I

have failed with Backwoods and always out shop their chassis but I have successfully

scratch built chassis in the past. I figured that I had to be able to

build this one myself. If successful, the kit is actually cheaper for me

than a Backwoods one. If I mess it up, it represents quite a loss!

The supplied instructions are a bit

deficient. For instance, the frets contain many tiny parts. There is an

image of the frets but there is no numbering and a key to identify all of

the bits.....and there are an awful lot of them. The written instructions

are 'terse' to say the least and frankly do not explain sufficiently well

for a beginner to tackle the job.

For starters, it would have been nice to have

a list of the tools required.

I used 2 soldering irons, (medium and small).

Baker fluid flux and normal and low melting point solder.

10BA and 12BA taps

wheel press

quartering jig is preferable

selection of small screwdrivers and files

Dremel tool

back to back jig for N gauge

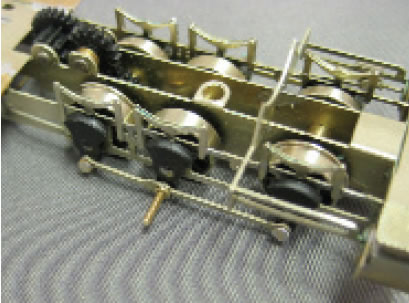

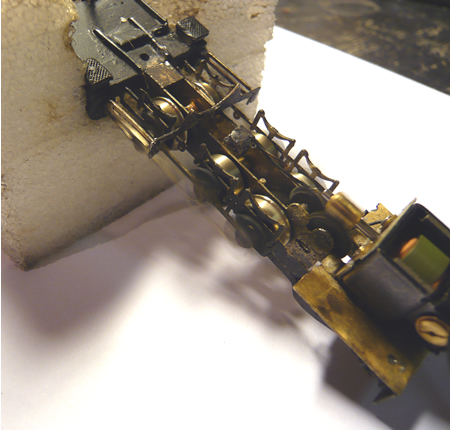

The design of the chassis is as things ought

to be. The is an inner chassis where the wheels are retained by a keeper

plate while the outside frames are slotted.

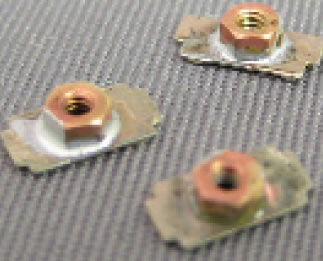

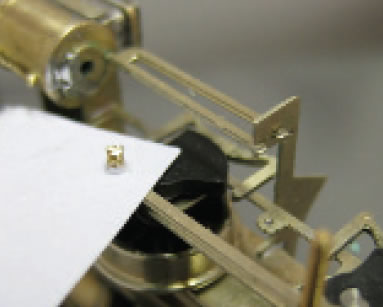

The first job was to remove the inner chassis

and fold it up. There are several places where small nuts have to be

soldered onto the frets. The trick to avoid having solder run into the

threads is to shove a cocktail stick into the hole and then it works fine.

Pity they did not mention this. I still do run a tap through captive nuts

to make assembly easier later.

The chassis should be soldered up on a sheet

of glass to ensure that it remains really flat. Once sure that the chassis

is properly square, I also ran fillets of solder along the fold lines.

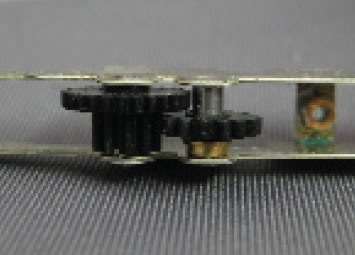

Almost straight away, you will be fitting the

drive train. There are two identical gears. One has a clearance fit for

the shaft while the other has a push fit. Make sure that the clearance fit

gear is used. The gear train is fitted as shown. The gears are designed

to rotate on the shafts while the shafts are held captive.

Prior to

installation, I tinned one end of each shaft and left a small blob of

solder there (here I used low temp solder). Once together I touched the

solder blob with a soldering iron fusing the shaft with the chassis. Great care is needed to

prevent over heating the gears. I always use plumbers flux which in my

mind gets things going with the minimum of heat. No instructions how to

fasten the shafts are given. Be sure to carefully wash the gear train with

hot water and detergent to remove the flux as soon as possible to prevent

any corrosion of the steel shafts. Drop a spot of oil into the gear

bearing surfaces.

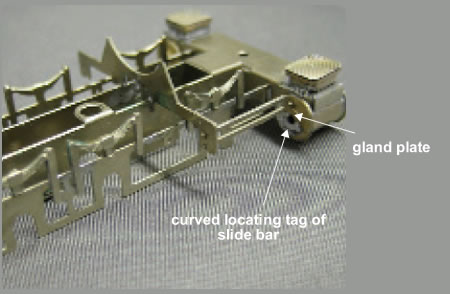

From then on, construction for a while

is straight forward. The brass castings are good quality but care is needed

to clean the cylinder blocks. The slide bars have a locating tag which

wraps around the gland plate. Make sure that the casting is properly

cleaned up here otherwise it will not fit. At

this stage, do not solder the slide bars onto the boiler support.

Quite quickly you will be beginning to have a

good looking chassis. The detail is really excellent by the way. The

equalising bars for the rear pony truck need to be cranked outward to give

sufficient pony truck movement. The instructions show two wires passing

across the chassis to fit them. Once soldered up, cut the wires out as

they will foul the rear truck.

Once you

have prepared the keeper plate you will find yourself fitting the wheels. The instructions suggest that 2 BA nuts are

soldered to it. This is where there is an error as the keeper plate

extends over the hole that will eventually house the front body securing

screw. It is better to shorten the keeper plate so that this important

screw is exposed. This means that the front pony truck needs to have its

length extended so that it attaches to the front keeper plate screw. At

this time it is good to solder the double washers over the end holes as

shown. These retain the pony truck arms while still allowing the screws to

be tightened. By the way, make sure that the small tags on the keeper

plate properly locate in the slots provided. Adjust them if necessary.

The 12 BA screws are all supplied long and

you will have to cut them down. Always run up a nut first and then cut and

clean up the end. Once you remove the nut, working it a little at the cut,

the thread will work.

The top hat bearings are seriously

engineered. The instructions do not tell you to

shorten a pair to allow for installation of the drive gear. IF YOU DO NOT

DO THIS, BUY TT TRACK! First, attach the gear onto one axle,

accurately central, locking it in place with Loctite 603.

The bearings need to have a flat sanded on

them and this is used to retain the bearings under the keeper plate. The wheels are simply pressed on making sure

that all of the bearings are fitted the right way round. Make sure that

the axles extend equally both sides and that the correct back to back

measurement is maintained.

If you have a quartering jig, fit the cranks

at this time. The 14BA screws are held in place with Loctite 603. While scale cranks are supplied in the etch,

Victors also supply push on plastic ones for idiots like me.

The

wheels then happily drop into the chassis (make sure that the bearings are

all of the way up the slot) and the keeper plate installed. The gear train

and wheels should turn freely and mine did first time.

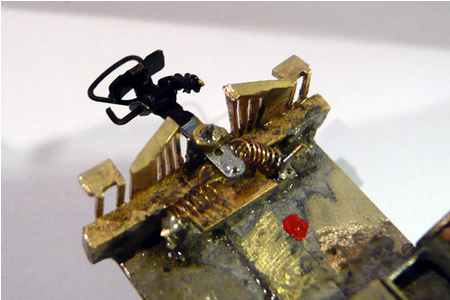

Again, omitted from the instructions is the

explanation of the electrical pickup. For Lord's

sake get all the wheels fitted the right way round. Otherwise

the dead short will be very disheartening when you put it on the track.

Confirm each time which are insulated wheels. I painted a red spot on the

live side to remind me.

The body and chassis is live and the tender

will be the opposite polarity so the link must be insulated and the tender

and locomotive must never touch! I chose to modify

this arrangement and the pillars supporting the bogies were built in solid

plastic. The bogies rub on an 8 BA washer and a thin wire is soldered to

this and lead to the cab. I found this a far better arrangement than the

suggested method and obtained more reliable electrical pickup.

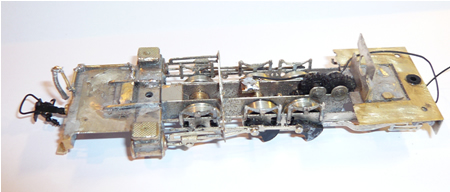

Check that the wheels all touch the glass

plate. If any distortion has happened, a small twist of the chassis is all

that is needed to adjust things correctly.

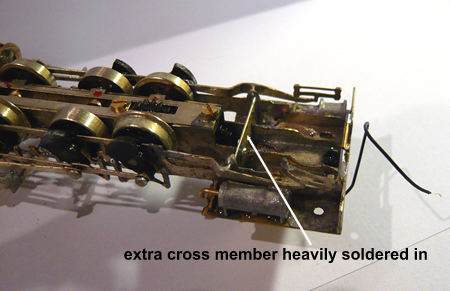

I did find that although the chassis sits flat on a sheet of glass, it is

a bit too flexible and could easily go out of kilter. I soldered in an

additional cross member once the outer frames and wheels were fitted which

had made the chassis far more rigid. One can also see how the rear pony

truck beams have been cranked out to allow for sufficient pony truck

movement.

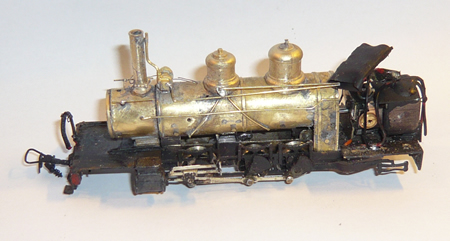

click on image to enlarge

If you do not have a quartering jig, the cranks are then added on one side. These

can be attached using epoxy or Loctite. The right hand cranks lead. Once

the glue has hardened it is time to add the other cranks and quarter. This

can be done by eye, using Loctite which

takes some hours to go off: 20 minute epoxy would work too. The connecting

rods need to have the holes opened out a tad, and I very slightly

slotted the holes except those on the drive axle which I left an accurate

fit. These should be temporarily fitted, being attached by a 14BA nut on

the centre driver. Check that you have the cranks properly quartered

before the crank attaching glue goes off!

The forward pins have to be cut back to clear the

slide bars. After about ten minutes of jigging the arrangement around, I

succeeded in getting the quartering right and the chassis move backward

and forwards without binding. One then leaves it a while to allow the glue

to go

off.

The forward and rear rods are attached by

soldering a washer onto the pin. Put a thin piece of paper between the rod

and the washer to prevent soldering the lot solid. I always hold the

chassis upright when soldering here which reduces the risk of solder

seeping down onto the rod. At this time leave the centre bolt as is and

remove the temporary retaining nuts.

I then installed

the motor. As the kit stands, the motor is a bit offset to the gear. I

slotted the bracket so the the worm gear was aligned directly over the

gear. After checking the mesh...gears should never bottom out, the chassis

was run for four hours each direction. Check that the motor does not over

heat at regular intervals. Perfect running straight off! Hey! I can build

this!

One error and a crankpin might have to be replaced. I would have liked to

see a couple of spares included.

The crosshead is riveted onto the connecting

rod and assembled. The last washers finish the job. Finally, the slide

bars are soldered onto the boiler support.

the coupling arrangement - click on image

to enlarge

The next job is to fold up the cab. This is

not as easy as it should be as the fold line is not sufficiently etched.

The real fun starts with fastening the boiler

wrapping around a brass tube. Firstly, I annealed the sheet with a blow

torch and gradually bent the sheet around, soldering as I went. The job is

a little difficult but the end result was just fine.

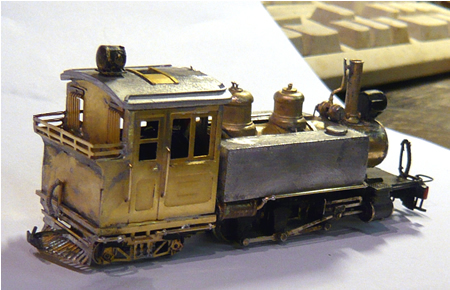

this shows my alternate way of fixing the front of the body - I can get

away with this solution as my loco is freelance! -click on image to

enlarge

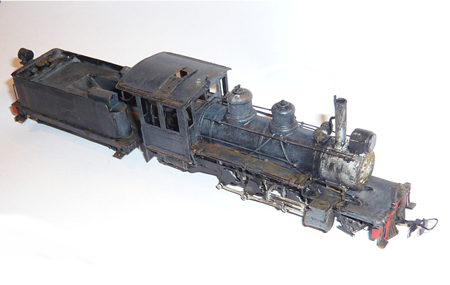

Now, talking about modifications, our loco is

representing a Baldwin delivered to the Glenthorne Harbour Authority which

is an awful long way away from Maine! In Devon they do not even put bells

around cows so why should steam engines have them. The 'Casey Jones' oil

lamps are also a casualty. These have been replaced by more modern

electric lamps and a steam generator. These are fitted with LEDs and will

be directionally operated by DCC. I cannot find the safety valves

either...ours are being fitted on top of the dome and of course we are

fitting a proper whistle.

The sandpot will also be installed with

sandpipes and an operating lever running to the cab. I am sorry, Victors,

I am incapable of building a kit without modifying it, even if a gun was

put to my head!

Now I do understand why Victors produce this

kit in HO scale, but we are 4mm scale, so a few changes have been made.

The holes in the boiler wrapping etch to take the footplate brackets were

filled with solder and new holes drilled 1.5mm lower....it is just that

our 4mm/ft guy are that much taller! To fit the footplates, I used an old

US modellers trick of passing .75mm rod right through the boiler and

soldering the footplate onto these. It is far easier to get things level

and a lot more robust. The rod will be shaped later. The rods were set

into the boiler with epoxy.

Well, we know that the instructions need to

be reworked. In the meantime, the pony trucks are fabricated from the

nickel silver parts which have a long slot. The end tab folds over to trap

the wheelset. The pony wheel sets also have one live wheel so for heavens

sake fit it the right way round. Remember to extend the front pony track

arm if you have modified the keeper plate.

The rear pony truck has this outer fret that

has been fitted. This needs to be cranked outwards otherwise there will be

no room for the truck to swing. I painted the inside of these with epoxy

to prevent shorting. The wheelsets have a small part of the axle

protruding and this should be removed. I added additional lead weight to

the pony truck.

CAUTION

The back to back

measurements of the small wheelsets are incorrect and need resetting.

The electrical pickup bears as it should do

on the back of the driving wheel sets. The clearances are very small and

it would be only too easy to get a direct short onto the chassis. I glued

a very thin strip of plastic strip onto the chassis to prevent this

happening.

The tender was harder than I thought. The

outer wrapping should be annealed with a blowtorch to make the bending

easier. It is still quite a challenge to get right. I did not bother

to have the tender body separately screwed to the base but soldered the

whole lot up together, leaving a largish access hole into the tender

cavity. I chose to incorporate a few dents in the tender.

If built to the instructions, the link to the tender must be insulated and

the tender is of opposite polarity. Remember all of the wheels pick

up on one side unless you opt to incorporate the modification

previously described.

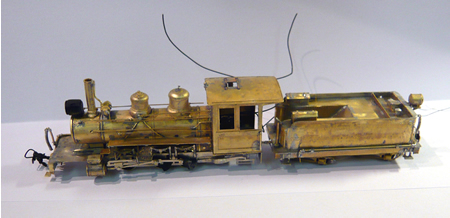

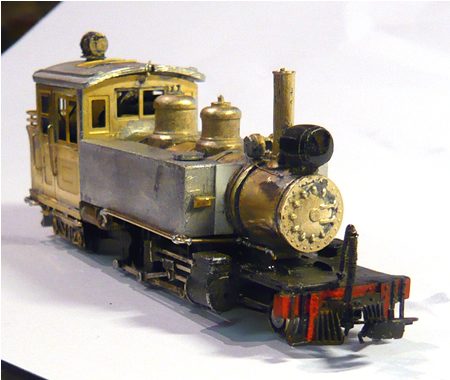

the 'British version' close to completion (pony trucks not fitted here) -

click on image to enlarge

Having fed the light wires through it, I

filled the boiler with lead shot mixed with epoxy. The tender was also

weighted as it was far too light.

So it is now going to be run for quite a few

hours (it is still DC) until is is really run it. It works, does not

waddle and has good slow speed characteristics which will improve with

running. However, after 8 hours running I noticed

that the bearings had slightly worn the retaining slots and had begun to

move around slightly. Knowing that all was well with the

alignment, I degreased the chassis and fastened the bearings onto the

inner chassis with 5 minute epoxy, taking real care to make sure that none

of it involved the drive gear on the rear axle. The glue could be easily

removed if necessary but it firmly retains the main bearings in the slots.

In all, the chassis has logged 12 hours

running without further problems showing up.

running in - click on image to enlarge

all that is left to do is the chipping, GHR decals and name/number plates

- click on image to enlarge

After painting and my usual weathering, the

glazing was installed. This was given a wash of thinned black to simulate

dirty glass which will hide the motor somewhat. I also painted the

armature of the motor black.

At which point, Whinge jumped on the work bench and dislodged the chassis

where is was running. This jammed the flywheel and the motor burnt out

..... thanks Whinge ...no turkey for Christmas!

I am also concerned with the very fine

flanges on the bogie and pony wheels for running on Peco track. This model

was designed for the US market. The wheels have now been replaced with

similar size but with 009 Peco profiles.

I have had similar problems with Backwoods

pony wheels and have always replaced them. I am hoping that a different

wheel profile is available when ordering the kit. There is a country mile

of differences between test tracks and real layouts and the derail rate is

too high to be acceptable. I tried the model with alternate pony trucks

and it works fine. The wheels that come with Greenmax bogies are perfect

for the job as they have the correct profile and are grounded on one side.

They are supplied by Wellington models.

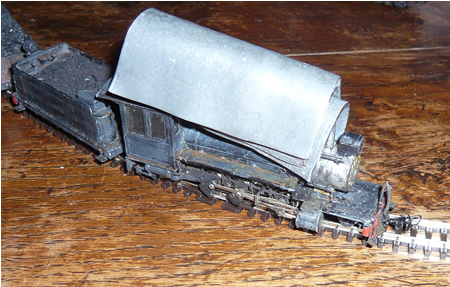

The next problem is that the traction of the

engine is very low. It is just too light to haul heavier 009 loads,

despite having been stuffed with lead wherever possible. Below is a photo

of the amount of extra weight needed to make the loco as heavy as our

'Lyn'. 3 large sheets of lead and 10 into 2 does not go! With this

ballast, the loco works perfectly. I have to say that all County Gate

stock is heavily ballasted including rolling stock and of course we have

some quite stiff grades.

The most sensible solution for me was to

convert the loco into a tank engine so that a lot of additional ballast

can be added.

No 19 alongside Lyn (that has solid lead tanks) very

similar in size and easy to convert - click on image to enlarge

butchery

I had not looked at a Langley 'Lyn' body kit

before. The brass frets go together very well but the one piece casting of

boiler and tanks left quite a lot to be desired, with some distortion and

flash that obscured some rivet detail. The tanks were cut away from the

boiler and the assembly went together in two days. There is now sufficient

weight for the engine to perform extremely well. A Langley bogie from a

wagon kit was modified as the rear 4 wheel truck.

ready for the paint shop - click on image

to enlarge

click on image to enlarge

click on image to enlarge

painted and awaiting lining and decals - click on image to enlarge

We used warm yellow 'lighthouse' LEDs

supplied by

Express Models . The body of the light is quite large although the

bulb is only 2mm in diameter. The bodies were 'lost' in the smokebox and

bunker. A resistor must also be fitted to bring the voltage down to that

required. I have to say that the yellow light looks so much better than

the ghostly blue tinted normal white LEDs. I simply set the LED in epoxy

and form a lens with a drop.

LEDs only work with the current running one

way. It is important to ensure that you wire them both the right way

round, otherwise your loco will remain 'dark'. The Digitrax DZ 125 chip is

used.

|