|

the great Roco chassis disappointment

When Roco brought out their outside frame

chassis, I have to say that I was very excited. Here, at last was a basis

for ordinary mortals to have more realistic and sweet running locos. There

was a drawback that the gearbox protruded well behind the rear driver and

in some cases made adding a pony truck impossible. Nevertheless, overall,

this seemed to be a great advance for 4mm narrow gauge modelling.

The cost was high, but acceptable for a high

quality product.

I quickly converted a chassis for my

'Russell' and even grafted on Backwoods valve gear. It worked like a

dream, smooth as silk, very slow speed....in fact, everything one could

possibly ask.

Drunk with this success, I followed this up

with fitting one under our Alco and then two under our freelance Mallet.

All seemed well with the world, until about 18 months later, Russell began

to oscillate. Very slightly at first but this quickly developed into an

impossible roll. Smooth running was a thing of the past and it was clear

that something very serious had happened. A little later, the ALCO

developed a small oscillation followed by the Mallet. I realised that £400

had been wasted on buying four joke chassis and I was not best pleased.

It was time to send Russell to our loco

doctor. After four days of work, the chassis was sent back with a note

saying that as far as he was concerned, it was scrap.

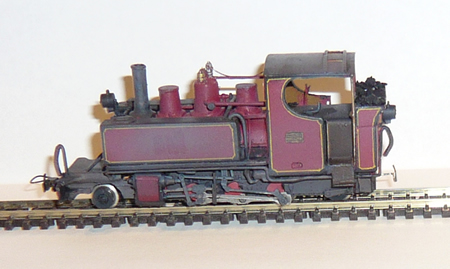

Mallet 'River Avon' on two Roco chassis

: time of chassis build 1 week

Alco on Roco chassis :

time of chassis build 3 days

R.I.P. Russell on Roco chassis

: time of chassis build 10 days

A grand total of £400 and 20 hard working

days. This is what we believe happens to these chassis.

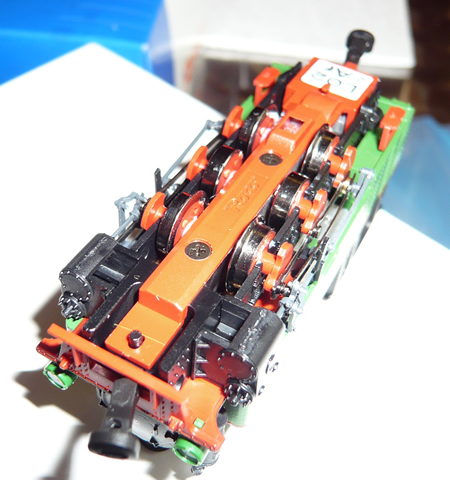

New Roco chassis

The steel axles run in slots in the die cast

chassis. They are held in place by a plastic keeper plate and the spring

pickups act on the flange tops. At first, the arrangement seems to work

very well indeed, but sadly, wear begins on the axles and chassis slot.

Once sideways play happens, things go from

bad to disastrous very quickly and the 'apple of your eye' turns into a

graveyard casualty very quickly indeed. Russell went first as the drive

wheel was operating scale Russell valve gear rather than the lightweight

plastic gear supplied. The other locos are, however, moving in the same

direction with standard Roco gear.

Many commercial locos are constructed in this

fashion, but not with outside gear. The axles on these chassis are

extended with a plastic moulding which includes the crank which clips into

the wheel. This passes through dummy outside frames. The result is

that the coupling rod is a long way outside the axle bearings and the

reciprocal motion of the connecting rod places much greater strain on the

bearings.

As the axles have only point running in the

chassis slot, it is not long before wear begins.

I am sure that this chassis will give good

service to many layouts which do not demand continuous running over

distances, but if you expect your locos to run well for a long time,

perhaps it would be a good idea to consider other alternatives such as the

excellent and much cheaper Grafar class 08 chassis.

For me, the perfect chassis has bronze axle

boxes and is driven on all axles, which prevents excessive wear on

coupling rods and pins.

|