|

Building the harbour branch railcar

no. 100

the railcar descends to the harbour

The plans to re-instate

the summer passenger service on the Harbour Branch for the 1928 season,

presented the Harbour Authority with a number of problems. The removal of

the run round passenger facilities both at County Gate and the harbour

meant that another solution had to be found. The six original coaches

belonging to the Authority had been in storage since 1914. Two were

modified to include a driving cab which was added to the coach by

extending the frames.

As progress began to

replace much of the main line service with diesel railcars, the Harbour

Authority decided to replace steam operation with a power car. The power

car was again built locally and employed two Gardner engines with

mechanical drive to the wheels. A complicated air control system was

installed between the cabs and the power car. Unlike its main line

equivalents, articulated bogies were not employed. This turned out to be

fortuitous as the power car remained troublesome throughout its life and a

steam replacement had to stand in on many occasions.

The railcar became very

popular during the summer as the branch had now become famous for its

spectacular views.

A few of our coach etches

had become slightly damaged when sent to customers and had been returned

for replacement. This was actually the start of this project as it seemed

such a shame to do nothing with them. I was also keen to provide trains

which were more visually different for exhibition use. What better than

this for the harbour shuttle service? As the trains enter the tunnel more

or less at right angles to the public viewing angle, this time the

lighting will be working, as our chips allow for this facility. We are

using dual colour 3mm LEDs from DCC supplies.

The coaches were built

from two damaged frets for L&B coaches

SR2473/2474

and one fret of

SR2469/2472

the driving cab

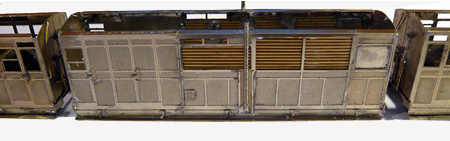

The power car, also made from 'bits'. The

vents are made by soldering brass rod on the inside. - click on image to

enlarge

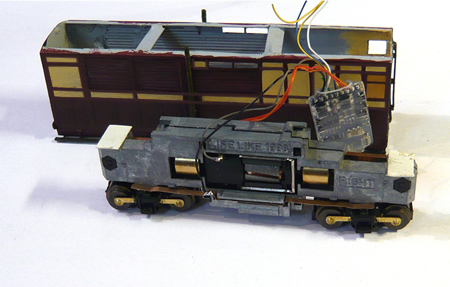

the Lifelike chassis ready for

installation. The plastic bogie sides have been removed to allow for

sufficient movement within the body. - click on image to enlarge

completed railcar set - click on image to

enlarge

Well, the build was fast

enough but we did have problems getting the lights to work. The lights are

switched on using function 0 on DCC. The instructions suggested that the

resistor be fitted to the common blue anode wire from the chip. However,

when the white light at one end was connected to the red at the other,

only the red lights worked. By trial and error, I discovered that by

adding additional resistors to the red light balanced things out and we

were able to get a red and while light working at the same time.

The lights are brighter

than 'scale' but I am quite happy with this at exhibition. The resistors

do get hot, so we make sure that the lights are turned off when the

vehicle is stationary.

Note that we discovered two wheel sets on the

Lifelike chassis that were not to gauge. While easy to adjust, all drive

wheels should be checked for back to back measurements.

The Glenthorne branch has several long

tunnels and there is a considerable distance which is cut into the sea

cliff face which exposes stock to salt air. The railcar was built out of

coaches built in 1910 that had been in storage for some time and some

timber soft spots had inevitably appeared. Following the construction of

the railcar, the paintwork quite quickly became a bit dilapidated. Due to the unreliability of the

'home-grown' power unit, steam was sometimes used while repair was

underway.

The painting hopefully reflects this.

The railcar was first spray painted with

automotive acid etch. The coach was then hand painted using acrylic

'Crimson Lake' and early BR cream. If we had wished that the coach looked

pristine, I would have waited 48 hours for the paint to harden and then

rub out brush marks and any nibs with a 2mm glass fibre pencil.

As we wished some weathering and soot, the

whole coach had dark grey weathering powder brushed over it while the

paint was till 'green'. The powder combines a little with the surface of

the paint. After waiting 48 hours, we then used the glass fibre pencil and

cleaned up the brush marks and some of the weathering powder until we had

obtained the required effect.

a trailer car following weathering and 'cleaning' -click on image to

enlarge

the power car following

weathering and 'cleaning'. some of the cream areas can be seen to have

peeled away completely. -click on image to enlarge

trailer fitted with

crests and destination board, chrome rim around light and windshield wiper

-click on image to enlarge

the railcar arrives at its bay platform

The chrome ring around the headlight was made

by wrapping round 3 turns of 3amp wire on the round plastic tube used for

building the light body and soldering the wire into one piece.

|