|

model railway engineering structures

It is essential to design and even build your

engineering structures prior to building your baseboard. If, for example,

you wish to incorporate a high viaduct, you may very well have to deepen

the baseboard to allow this to happen.

I always build these structures on a sub-base

that can later be properly attached to the baseboard. The structure is

fully detailed, painted and the track laid. I also complete the scenics

around the structure as it is a lot easier to do on the workbench. Notice

in the photo below that I have left a lip along the edge which I can later

pick up to extend the scenics.

I also add thin plywood lips to the end of

the trackbed which will be used later for accurately attaching the

adjacent trackbed.

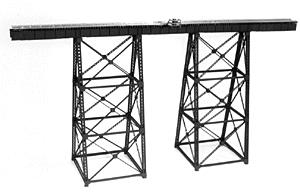

Most steel bridges are quite challenging to

scratch build but many commercial products are available, some ready built

and others in kit form. Some beautiful etched products are available from

the USA such as those shown below. They can usually be 'bashed' to achieve

what you require.

The British market can also help. Peco, for

instance supply truss bridges and plate girders in both 00 and N scale and

further selections are available through their Wills and Ratio product

lines. Some examples are shown below. Other sources can be found in our

resources

pages. How we built the East Lyn Viaduct can be found

here.

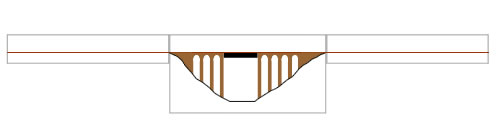

Wills model of the cast

iron Festiniog bridge

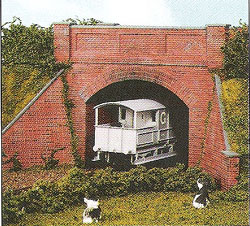

Wills OO Brick Arch Bridge is wonderful for 'kit bashing'

we used this cut down version for the bridge at County Gate. Note the

stalactites on the underside and the sooted brickwork

Wills viaduct

sections

Tunnels are often used on model railway to

'lose' trackwork off scene. Usually, only one side of the tunnel

interior is visible. This is fortunate as the unseen part can be

omitted, thus giving more access to the track. When designing tunnels,

please remember that it is essential to provide access for track

maintenance and rolling stock recovery. I miscalculated this at County

Gate at one section of the tunnel under the Glenthorne cliffs. Human

arms could just not reach one part! This resulted in some interesting

moments with a vet's endoscope which must have been in some quite

unpleasant places beforehand, followed by some scary moments with a

jigsaw!

I usually favour building up topography

with lightweight blue foam. This method is inappropriate if track is to

be hidden below as much better access is required. Here, shell

topography should be used, such as plaster bandage laid on chicken wire.

hidden tracks inside

the tunnels with access holes for maintenance.

hidden tracks inside

the tunnels with access holes for maintenance.

Nothing looks worse that daylight coming

out of a tunnel. Make sure that light can be blanked off from the

interior. I often use lightweight black panels which attach with Velcro

to seal off access panels.

If you are to install a tunnel portal, you

do have quite some choice available. Make sure that the tunnel bore size

is appropriate for the rolling stock. Tunnels were rarely built larger

than necessary.

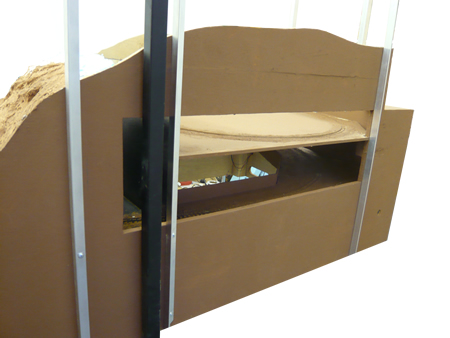

A very clever way of disguising the exit of

track from the viewing side. Behind the backdrop is an additional small

section of scenery before the track runs into the hidden fiddle yard.

A very clever way of disguising the exit of

track from the viewing side. Behind the backdrop is an additional small

section of scenery before the track runs into the hidden fiddle yard.

The edges of our layouts are effectively

sectioned right through the Earth's crust and somehow our eye accepts

this. If alongside the 'edge of the world' is a hidden track, then

one can display the inside of the tunnel; a most unusual view. We decided

to do this on our hotel model.

The trains become visible

to visitors in the unique environment of the inside of a tunnel.

Hopefully, most people have not entered into a working railway tunnel and

long may it remain so!

Once we had decided where the tunnel would be

sectioned, the first job was to fabricate the tunnel wall. This was done

in foam board covered with Polyfilla which was moulded and

subsequently carved into hewn rock. The plaster was painted in dilute

acrylics and then with weathering powder.

the new tunnel section ready for installation

Once the rock wall was fitted, the track was

ballasted and talus was scattered in places to represent rock falls.

Again, the track and ballast was painted and then clear epoxy resin was

used to paint on wet walls and pools of water in the ballast. Once cured,

I painted over the epoxy with glass varnish, which looks better at the

edge of puddles, being much thinner than epoxy.

the

completed sectioned tunnel

A

unique view of the tunnel mouth from the inside. The pools of water lying

in the tunnel can be clearly seen.

|