|

Lynton and Barnstaple model

signalling

by Bob Barnard

ed note: Bob is a professional

signalling engineer and his work in this field is seminal. It also shows

what happens when you bring your work home!

The definitive description of the signalling arrangements on the original

L&B line is given at:

http://www.trainweb.org/railwest/lbrsignals.html

There are still many unknowns about details of the original signalling,

and the operation of the line, but this website includes what is probably

the best information available to date, and is updated if new information

comes to light.

|

Technical Standards for Model L&B Signalling |

Although my L&B model is an attempt to recreate the original line in

009 scale, in order to be able to operate it in a manner equivalent to the

original line, there are some areas where alternative signalling standards

have been devised, in order to overcome the practical constraints of a

small-scale model. Obvious differences from the original signalling

include:

• There is no need for telephones to allow operators at different stations

to converse, as the layout is housed in one room

• It is not practical to carry physical tablets on 009 trains (4mm scale

working tablet instruments would be a step too far!)

• Lever frames need to be large enough to suit 12”/1 foot scale fingers

• It may be necessary to operate stations from either side, especially at

exhibitions

• Facing point locks are not really required on a model, especially as

those on the L&B were “economical”, i.e. they did not involve the use of

separate levers

• L&B level crossings were released from the

nearest signal box, and operated locally by hand. This may not be ideal in

a model situation.

I wanted some system to replace the tablet instruments for single line

sections. On some secondary routes around the world, so-called “Tokenless

Block” systems are used to release the signals controlling entry to single

line sections, and this seemed like an ideal solution for my model.

Therefore, I developed a Tokenless Block System (TBS) based on BR

practice. In order for this to operate, it needs to be interlocked with

the starting signals at passing loops, which the Tyers instruments on the

original line were not. However, this seemed to be a sensible compromise.

Surprisingly, in view of its suitability, I am not aware of tokenless

block having been used by other modellers.

Many model layouts these days use oversize but realistic-looking lever

frames to control points and signals. This provides a satisfyingly

authentic method of operation. A few of these models also have working

mechanical interlocking between the levers. With very simple track

layouts, I decided that my long-term aim should be to provide full

mechanical interlocking.

It is possible to build-in the lever frames into the station layouts, and

operate points and signals mechanically by rodding under the baseboards.

However, this effectively prevents operation of the station from the rear

side. The alternative is to build a separate “signal box” unit, and

operate points and signals electrically. I have used both approaches in my

L&B models.

A set of common engineering standards has evolved as I have built my

models, so that spares can be used at any station. These standards include

power supply arrangements, block circuits and electrical drive

arrangements for points, signals and level crossings.

A number of interim signalling arrangements have been implemented on the

model, in the interests of saving time, but it is intended that these will

eventually be brought up to the general standard.

The following sections include more detailed descriptions of the common

subsystems.

A standardised form of Tokenless Block

control is used for each single line section, using one circuit in each

direction in a lineside cable route, and providing facilities for

acceptance of trains and release of signals. The tokenless block system

also provides block bell communication between stations.

The Tokenless Block System is a method of controlling single line sections

without the use of physical tokens. It is derived from British Railways

Tokenless Block systems, and is intended for implementation on model

railways.

In order to clear the starting signal for a train to proceed into the

single line section, it is necessary for the signalmen at the two ends of

the section to establish, by the correct sequence of operations, that the

line is clear. The signalmen can then set the block section for the

appropriate direction, and the appropriate starting and home signals can

be cleared according to normal block working methods. When the train

arrives complete at the other end of the section, that signalman

normalises the block once again, ready for another train.

At each end of the section, there is a block instrument and a relay set.

The relay set contains 4 relays and is fed from a local 15 Volt a.c. power

supply, and requires contact inputs indicating the status of the home and

starter signals at the station. It provides 12 Volt d.c. outputs to the

home and starter signal lever locks.

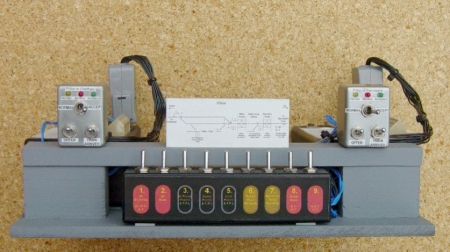

Tokenless Block instrument (l) and Relay Set (r)

The circuit between the relay units at the

two ends of the block section consists of two conductors and a common

return path.

The system is designed for use with semaphore signals with electric lever

locks. Additional circuits can be added to interface to colour light

signals.

The normal sequence of operation for the section between A and B is as

follows:

• After the passage of a train and the normalisation of the block, each

signalman sets his block instrument to “Accept”, provided no shunting is

taking place into the block section. The block status is indicated to both

signalmen as “Normal” (Yellow)

• When the next train arrives (say) at A, the A signalman sets his block

instrument to “Normal”. He then presses “Offer”

• At B, automatic acceptance of the train

occurs, and the block status is indicated as “Blocked” (Red). If the B

instrument were not set to “Accept”, this would not occur, and an audible

warning would be given

• When acceptance has occurred, the block status at A is indicated as

“Accepted” (Green)

• The A signalman may now, at any time, release his starting signal

towards B, using the economiser button to energise the signal lever lock

as he pulls the lever. As the signal clears, the block status changes to

“Blocked” (Red). If he replaces the starting signal to danger, he cannot

then clear it again. This prevents a second train being accidentally

signalled into the section.

• The B signalman can now, at any time, clear his home signal from the

direction of A, using the economiser button as he pulls the lever. If he

changes his mind about the route for the train, he can replace his home

signal to danger, move the points, and then clear it (or any other

appropriate home signal) again

• The A signalman replaces his starting signal to danger once the train

has departed from A

• The B signalman replaces his home signal to danger once the train has

arrived at B

• The B signalman checks that the train has arrived complete at B (tail

lamp) and then sets his block instrument to “Normal”, and presses “Train

Arrived”. The block section status is then restored to “Normal” and

indicated to both signalmen by “Normal” (yellow) indications

• Each signalman then sets his block instrument to “Accept” again,

provided no shunting is taking place into the block section. The block

status is indicated to both signalmen as “Normal” (Yellow).

The Block Instruments are located on

(non-prototypical) block shelves over the lever frame at each station. Two

different designs of relay set are used, but all units have standard

connectors for the block circuit, allowing any two stations to be linked.

The two instruments at a passing loop can also be linked to one another

for testing. The appearance of the block instruments is very 1960s, with

grey boxes and labels against each indication or switch.

This tokenless block system works extremely well, and again gives an

authentic feel to operation of the model, even though it is quite

different to the original Tyers tablet system used on the L&B.

Lever frames, with mechanical interlocking between levers, are (or will

be) provided at all stations and passing loops.

Home and starting signal levers are released, when permitted by the

Tokenless Block system, via 12 Volt d.c. solenoid lever locks fitted with

economiser buttons. Signal clearance is dependent on local detection of

electrically operated points and level crossings, and of slots from

adjacent signal boxes.

Two alternative approaches to point and signal control are adopted:

• The lever frame, interlocking and block shelf may be located at the

station itself. In this case, station area points and signals are operated

directly from the lever frame via rodding, and detection is provided

purely according to lever position.

• The lever frame, interlocking and block shelf may be remotely located

(or portable, for ease of maintenance), and connected to the station by

multicore cabling (D-type computer cables, 9 way and 25 way). This

approach means that a non-interlocked switch panel may be used as an

interim solution, in place of a fully interlocked lever frame.

In the case of electrical operation, the lever frame (or switch panel)

provides feeds as follows:

• 12 Volt d.c. feed, switched in polarity by the lever, is used to feed

each electric motor (slow-acting) point machine. Electrical point

detection is provided, with a correspondence circuit used to release a

lever lock to allow the controlling lever to reach the fully normal or

reverse position.

• 12 Volt d.c. feed, switched in polarity by the lever, is used to feed

each semaphore signal via local point detection contact(s). Signals may

therefore, in principle, be operated by several different types of

mechanism:

o

12 Volt d.c. relay mechanisms, via a diode

o

12 Volt d.c. motor mechanisms (e.g. slow-acting point machines)

o

Memory wire mechanisms, via a diode (tried but not used)

o

Direct operation of bi-colour LED colour light signals (not used)

In all cases, electrical "Signal On" detection is provided at the signal,

either by detection switches or by contacts of the operating relay

mechanism

• 12 Volt d.c. feed, switched in polarity by the lever, is used to release

each level crossing.

Unlocked mechanical ground frames are provided at in-section sidings.

It would be possible to prove ground frame levers normal by means of

contacts in the TBS line circuits. This would prevent the section being

cleared with a ground frame incorrectly set, neatly replicating the

prototypical feature whereby the block cannot be released if the ground

frame is left unlocked.

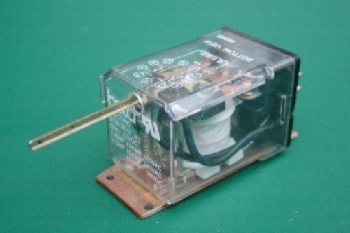

The current standard mechanism for operating signals is a Maplin 12 Volt

d.c. power relay. These are modified as follows:

• Bend the contacts apart slightly, to increase the travel of the armature

• Attach an arm made from a piece of Code 100 rail to the armature, to

extend the travel

• Drill a large hole in the plastic cover for the arm to pass through

• Attach a mounting plate to the cover, for screwing to the baseboard.

Relay signal mechanism

Interlocked points (e.g. loop and siding entry points) are operated by one

of two means:

• Directly by robust mechanical rodding from the lever frame

• Electrically by 12 Volt d.c. slow-acting electric machines (either

Fulgurex or Lemaco).

In either case, the drive is taken by plastic covered galvanised garden

wire to a substantial brass crank fixed under the points, where the throw

is reduced to about half. A long steel pin in the shorter arm of the crank

projects through a slot in the baseboard and passes through a hole in the

fibreglass tiebar linking the point blades. A “joggle” is incorporated in

the garden wire, to allow small adjustments to be made in situ with

pliers.

Point machines use a standard 12 Volt d.c. 3-wire drive and correspondence

circuit, with wiring details defined for each type of point machine.

Point machines are fitted with 3 pairs of detection contacts (Normal/Not

Normal and Reverse/Not Reverse), which are used as follows:

1 pair for motor current cut-off and correspondence circuit

1 pair for traction current switching

1 pair for detection in signal circuits

No facing point locks are provided.

It would theoretically be possible in future to use electronic presence

detectors to replicate the operation of the economical FPLs.

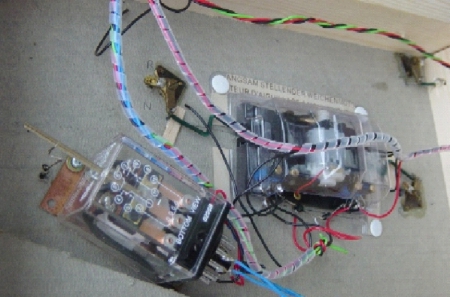

A signal relay mechanism (l) and point machine (r) installed under a

baseboard. The point machine drives the loop points and trap points, via

the cranks at either end of the mechanism

Yard points are unlocked, and are individually operated by local switches

via robust rodding. No detection of such points is needed in signal

circuits, and the switch contacts control traction current.

Level crossings are released by a 12 Volt d.c. feed, switched in polarity,

from the lever in the controlling signal box.

Level crossing gates are operated by a 12 Volt d.c. electric motor, via a

mechanism that sequences the gates. The mechanism includes a

correspondence circuit operating the lever lock, to prevent the

controlling lever completing its movement until the gates have been

operated and detection switches have proved the crossing gates closed to

road traffic.

Local switch panels are provided near each crossing. These switch panels

provide two modes of operation:

• In “Local” mode, the release from the signal box is indicated to the

local operator by a “Open” (Green) indication, and replacement of the

crossing lever in the lever frame by a “Close” (Red) indication. When an

indication is present, the local operator may, in his own time, operate

the gates using the “Operate/Halt” switch on the local control panel.

• In “Remote” mode, release of the gates by the signalman causes them to

open, and replacement of the lever causes them to close. Operation of the

“Operate/Halt” switch on the local control panel stops the gates moving

immediately, in the case of an obstruction or fault.

Each crossing is detected closed to road traffic in the circuits releasing

signals reading over that crossing.

All signalling is fed from a nominal 15 Volt a.c. power supply provided at

each station. This supply is used directly by the tokenless block system,

and is rectified and smoothed for use by the point machines and lever

locks. Signalling power is normally fed from separate transformers from

the traction power, to prevent momentary loss of signalling power during

traction short circuits following derailments. However, the choice of 15

Volt a.c. means that, for testing purposes and for exhibitions, traction

power and signalling power can be derived from a single controller.

|

Provision for Degraded Modes of Operation |

It is very desirable to be able to continue to operate traffic following

failures of the signalling system. The design philosophy addresses this

issue by means of the following measures:

• Mechanical interlocking and rodding to points and signals, once

adjusted, is regarded as inherently simple and reliable, and no special

provisions are made to work around failures of such elements. “Joggles”

are incorporated in rodding, to permit simple adjustment in situ.

• Electrical operation of points and signals is more prone to failures,

mainly of electrical connections or of the adjustment of sensitive and

inaccessible detection switches on the lever frame. Interim switch panels

used prior to completion of fully interlocked lever frames are therefore

retained for test purposes and for emergency use whilst lever frame faults

are repaired.

• Failures of the block system can prevent the release of electric lever

locks, and therefore prevent clearance of signals. Lever locks are

therefore now designed to be operable manually, by lifting a pin, to

permit signal clearance under such failure conditions.

The principal remaining vulnerabilities to signalling failure are as

follows:

• Failure of the fragile soldered connections to point blades. These

failures are relatively frequent, but are quite easily repaired in situ

• Risk of jamming of an electric point machine drive. There is currently

no effective method for working round such a failure, although it has not

been a problem to date.

Three main areas of improvement of the signalling are foreseen:

• As an interim measure, a simple relay circuit has been devised to permit

signal clearance to be dependent on the TBS status on installations with

unlocked switch panels. This will be added at Barnstaple Town as a trial

in the near future.

• Lynton station is due for a rebuild (mostly scenic). At the same time,

some small improvements will be done to the signalling.

• Completion of fully-locked lever frames for Barnstaple Town and Pilton.

MSE parts have already been acquired to start work on Pilton. Perhaps a

job for next winter….

|

Model

Signalling on the Layout |

The signalling contributes a lot to the overall appearance of a model. The

various visible elements of signalling system are modelled carefully, just

like any other aspect of the model.

|

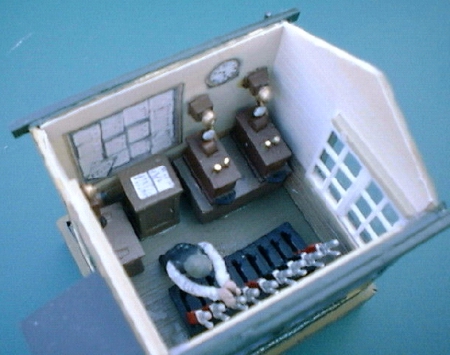

Signal Boxes, Huts and Ground Frames |

Each of the three signal boxes on the L&B were different in design, and

their construction is described site-by-site in the following sections.

Generally, interiors are fitted to signal boxes, using commercially

available whitemetal parts.

The signal huts at intermediate stations were quite rudimentary, and are

scratchbuilt from thin ply and plastic sheet. The doors are left open, so

that the tiny “knee” frame is visible within.

Ground frames are represented in the model, where their location is known

from photographs (i.e. Pilton and Lynton), although the type of frame

modelled is not necessarily 100% accurate.

The actual signal structures on the model represent the signalling as it

was in the latter days of the line’s operation. There are a mixture of

wooden post signals with lower quadrant arms, lattice post lower

quadrants, together with a few typical SR rail-built signals – mostly with

lower quadrant arms, but one (Woody Bay Up Home) with an upper quadrant

arm.

Some signals have been completely scratchbuilt, with stripwood or Code 55

bullhead rail posts, and fittings fabricated from brass and nickel silver.

However, the excellent Model Signal Engineering range of etched brass

components have been used more recently. In particular, their lattice post

parts cannot be beaten by scratchbuilding (I know, I tried – once). I have

assumed that LSWR components are the most appropriate in terms of the

style of arms, lamps, etc.

On the model, the functional point machines, signal relays and cranks are

obviously installed well out of sight under the baseboards. To give the

correct appearance on the model itself, non-functional point rodding,

cranks, etc. are added to each layout, following the correct routes from

the signal box to the points. On some sections, this rodding uses square

steel wire running in tiny stands, assembled from etched brass components,

between etched brass cranks, which were bought as a pack many years ago.

More recently, I have used round brass rod (the L&B had round point

rodding) running in stands made by drilling holes in small plastic “T”

section material. When painted with rust colour, the effect is quite

acceptable from normal viewing distance.

The L&B facing points were mostly fitted with fouling bars, unusually

installed outside the running rails. As the lever for a set of points was

moved by the signalman, the economical facing point lock mechanism caused

the fouling bar to rise above rail head level as the lock disengaged, and

fall again as the lock engaged after the points moved. Clearly, if a train

was approaching the points, the fouling bar would be unable to rise, and

the points would remain safely locked.

These fouling bars are represented in the model by a length of square

steel wire soldered outside the rail head just below the upper surface,

and a crude representation of the rodding is added.

Ratio plastic telegraph poles are installed on the layout, at the

locations shown in photographs. These poles are cut down to give the

correct number of insulators. In addition, based on photographic evidence,

there are various places where insulators were provided on buildings, and

even on a signal post, to allow telephone and tablet instrument circuits

to reach the desired locations.

The signalling implemented on the model is currently as follows:

The overall architecture of the model L&B signalling is currently as shown

in the following diagram:

Signalling power is derived from a single Radiospares 230V/15V dual

secondary transformer housed in a box, via radial 15 Volt a.c. feeders to

each station. Because of the use of a single transformer, connectivity

between a.c. power sources and tokenless block circuits has been

standardised, since otherwise it is possible to create short circuits via

the TBS return conductor.

The transformer secondary windings have separate fuses; one secondary

feeds Lynton and Woody Bay and the other feeds Pilton and Barnstaple Town.

The standard power supplies at each station include a series 15 ohm

resistor, slightly reducing the voltage on the point machines to improve

their life, and also limiting fault currents. The inclusion of these

resistors means that points and level crossings should be operated

sequentially.

The

hand-built wooden post junction signals at Lynton were installed when the

layout was constructed during the 1960s, but were not initially

operational.

Lynton Up Starting Signals

Points were originally operated by solenoid

point motors, which proved unreliable. The lever frame and mechanical

interlocking was built around 1980, and was installed on the layout

itself. The Tokenless Block equipment, block shelf and electric lever

locks were added a few years later.

Mechanical operation of points and signals is

by direct rodding from a hand-built lever frame next to the model signal

cabin at the station. The lever frame incorporates mechanical interlocking

between points and signals. Levers are not necessarily arranged in

accordance with the prototype numbering (which is not known).

Lynton lever frame (l) with its Tokenless Block instrument, and the TBS

relay set (r)

Traction switching is achieved via a single microswitch on each point

lever in the locking frame. Signal On detection is via a similar

microswitch on each signal lever. Due to the simplicity and robustness of

the mechanical rodding, no local detection of point position is provided

in signal controls.

Tokenless block for the single line section to Woody Bay is provided, with

a block instrument on a block shelf behind the lever frame. The TBS

interfaces to electric lever locks on starting and home signals.

The run-round crossover and goods yard points are locally operated by

means of an unlocked 2 lever ground frame located next to the run-round

loop.

The model of the small signal box at Lynton was scratchbuilt some 40 years

ago. Signal

operation at Lynton has become unreliable, and some repair work is

currently needed to render the home signals fully functional.

A minor change to the point control and the mechanical locking is also

necessary to provide flank protection for passenger trains, to comply with

the prototype. This error has emerged in the light of further research.

Signal lever locks may be replaced with the more recent standard design,

to allow them to be manually released in the event of failure of the

Tokenless Block system.

It is planned to relocate the ground frame for the run-round and goods

yard points to the correct place at the end of the bay platform.

Scratchbuilt wooden post and rail-built signals were installed at Woody

Bay when the station was built in the early 1970s, but they were not

operational at that time. Points were originally manually operated by

rodding.

The Woody Bay lever frame was constructed and commissioned during 2000/1,

and the signals were made operational at this time.

Up end points are controlled by Fulgurex machines. No. 5 points

(double-ended) have a non-standard arrangement for traction power

switching (A end switched by N-/N switch, B end by R-/R switch), as the

point machines have insufficient contacts for two sets of traction

switching using the normal method using N and R contacts. This leaves the

possibility of brief short circuits if the points are moved whilst trains

are running.

Up end signals are motor-operated, using Fulgurex machines fed via local

point detection contacts. This solution was adopted because, at the time,

I had no suitable large relays to drive them, and experiments with Memory

Wire, although promising, appeared to show the need for frequent

adjustment to cope with temperature variations.

The down end points are controlled by a Lemaco machine. Down end signals

are semaphores operated by modified 12 Volt Post Office 3000 type relays,

whose contacts also provide the "signals on" detection interfacing to the

tokenless block.

Woody Bay Up Home signal – the only upper quadrant on the line

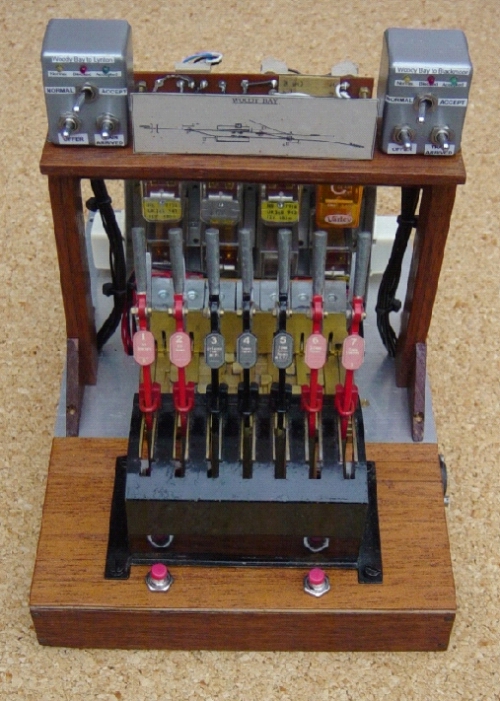

A free-standing 7 lever Model Signal

Engineering (MSE) lever frame is provided, with electrical switches for

point and signal operation. Interlocking between points and signals is via

a mechanical locking frame. The lever frame is connected to the station by

two 25 way cables. Levers have the original L&B numbering.

Woody Bay Lever Frame. The TBS relay sets are behind the locking frame

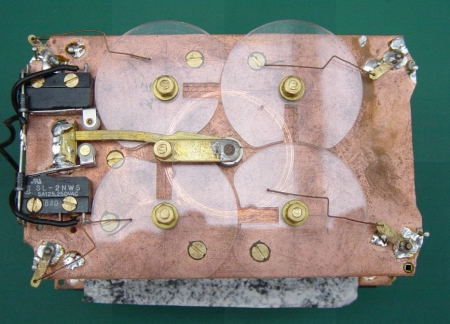

Mechanical locking tray at Woody Bay, with electric lever locks (l)

Tokenless block is provided for the single

line sections towards Lynton and Blackmoor.

The lever frame is modelled with the correct orientation, as per the

prototype, where the signalman faced away from the track on the up

platform (Lynton to the left, Blackmoor to the right). However, as

currently installed, the model station is "the wrong way round", leaving

the operator with Lynton on his right and Blackmoor on his left. This is

not a serious problem, as the L&B lever numbering was not particularly

logical (it may originally have been intended to provide distant signals

approaching loops, rather than starting signals). The biggest difficulty

is that the (non-prototypical) block instruments are at the "wrong" ends

of the block shelf in this situation.

The signal hut at Woody Bay is scratchbuilt from thin ply.

Woody Bay Down Starter – an original Evans O’Donnell wooden post lower

quadrant signal

Lyn passes Woody Bay Down Home signal – a tall rail-built lower quadrant

The Up starting signal and the Down Home

signal, which are currently motor operated, will be converted to relay

operation, to bring them into line with other stations, and to allow the

point machines to be reused elsewhere.

Pilton Yard was built around 1980, and at that time all points were

operated by individual toggle switches via mechanical rodding. No signals

were provided at that time.

An interim switch panel was built in 2003, and outside equipment assembled

and tested prior to its final installation in stages during 2004.

Outside equipment on each baseboard is connected to the lever frame by

D-type cables. The Down end points and signal are connected by a 9 way

cable, and the Up end points and signals via a 25 way cable to a

distribution panel, from which three further 9 way cables link to Pilton

Road crossing, Braunton Road crossing, and to the Down Home signals. A

further connector is provided for eventual slots from Barnstaple Town (SR)

Signal Box.

Signals, points and level crossings are all electrically operated from an

interim lever frame consisting of 9 unlocked switches. This unit also

houses the TBS and block instruments.

Pilton Interim Switch Panel, with block instruments

The Down end yard exit points are operated by

individual local switches and rodding, rather than a ground frame. No

electrical release or detection in signal controls is provided.

The Up end loop and yard exit points are operated by Lemaco point

machines. The trap points at the up yard exit are non-functional, due to

restricted space beneath the layout.

A MSE LSWR-type lattice semaphore Up Home signal is installed, and is

operated, via a local point detection contact, by a modified Maplin power

relay.

Pilton Up home signal. The dummy fouling bar is just visible to the left

of the track The

Up Starting signal is constructed from an MSE lattice post with lower

quadrant arm. It is operated by a modified Maplin power relay. This signal

is actually attached to the fellmonger's yard scenic add-on that attaches

to the front of the layout, and so it is plug-coupled to the main

baseboard. The local point detection circuits allow the up starting signal

to be cleared either for moves from the up loop or from the yard. With

hindsight, this signal is a little too tall.

Pilton Up stating signal, with Pilton Road crossing in the background

The Down Home signal, with

its main and shunt lower quadrant arms, is constructed from an MSE

whitemetal "wooden" post, with rather complex platforms to allow access to

the two lamps and arms. The shunt arm is provided with a black circle,

although the use of such an arm appears to deviate from SR standards of

the time. The red spectacle on this arm is of reduced diameter. Three

groups of operating levers and balance weights are provided in an attempt

to represent the slotting of these signals from Barnstaple Town L&B box.

The main and shunt arms are operated by two modified Maplin power relays.

A train for Lynton passes Pilton Down Home signal; the second arm is for

entering Pilton Yard

As Pilton had no down

starting signal, it was necessary to simulate one, to allow the TBS to

operate correctly. This was achieved by means of a relay circuit operated

by the lever lock release.

As yet, there is no interlocking between points and signals at Pilton,

although signal clearance depends on local point detection. Yard points

are all operated by individual local switches at the front of the layout

(actually in the mill leat!).

Mk2 Tokenless Block units are provided for the sections towards Barnstaple

Town and Chelfham.

Pilton signal box is constructed using parts from a Ratio plastic kit,

extensively modified to resemble the prototype as closely as possible. The

interior includes models of the two Tyers No. 7A tablet instruments that,

here alone, were located in the signal box.

Pilton Signal Box – the tablet instruments are the boxes with white

indicators and brass plungers (top right)

It would be desirable to link the down end

yard exit points, and control them from a single lever unlocked ground

frame, similar to those provided for the quay siding and at Lynton, since

the present switches are rather inaccessible (buried in the undergrowth!).

It is intended that the signalling will be

controlled from a remote 9 lever MSE lever frame (i.e. a similar design to

Woody Bay). The locking conditions for this lever frame have been defined

and tested by simulation. More recently, advice has been sought from the

specialist on L&B signalling about the most probable lever numbering for

this lever frame.

Pilton Road crossing was constructed in 2003. It is electrically-operated

by means of a Fulgurex point machine, with gates sequenced in pairs.

Detection is provided by switches on the point machine itself.

The crossing is controlled from the interim switch-based lever frame at

Pilton, via a local control unit hidden in bushes. Signal clearance is

conditional on the crossing being proved open to trains.

The operation of the gates in pairs is not very pleasing, and the gates

move too quickly. The crossing unit could be rebuilt with a mechanism like

that at Braunton Road, as time permits.

|

Rolle

Quay Siding Ground Frame |

A single lever unlocked ground frame is fitted. This is built from parts

of an old GEM lever frame, and set into the surface of the yard outside

Baker's Mill. The ground frame is (correctly) not detected in signal

circuits.

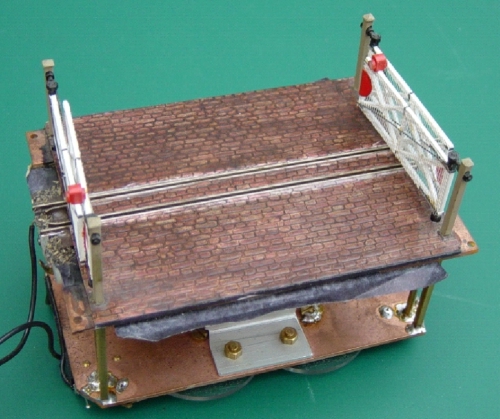

The model of Braunton Road crossing was constructed as a removable unit

during the 1990s, and incorporated in the loft layout more recently.

The electrically-operated fully-sequenced overlapping gates are driven

from a single Triang X04 motor via double worm gearing. An arm rotates

slowly round slots in four interlocked Perspex discs, which each move

through 90 degrees in turn. Detection microswitches cut the motor power

when the arm reaches the end of its travel. Each gate is driven from one

of the Perspex discs by phosphor bronze wires and cranks. The drive method

is a distant memory from the Meccano Magazine in my youth!

Top view of Braunton Road crossing mechanism with its overlapping gates

Underside of the same crossing. The brass arm rotates 360 degrees

anti-clockwise to operate the gates

The crossing is controlled from the interim

switch-based lever frame at Pilton, via a local control unit, allowing

either remote control or remote release and local control. The control

unit is housed in the doorway of North Gate House, adjacent to the

crossing.

Signal clearance is conditional on the crossing being proved open to

trains. To achieve this, a "Gates Open" detection relay is fitted on the

operating mechanism to provide multiple contacts for local detection of

the crossings in signal circuits.

The appearance of this crossing is most satisfactory in operation – one

can almost imagine the crossing keeper walking round opening each gate in

turn….

This station was constructed in a short

period in 2003/4. Motor operation of the points and relay operation of the

L&B starting signal were included from the outset.

Points are controlled by Fulgurex point machines located under the

baseboard. Switches on these machines switch traction power to the track.

The trap points on the run round loop and the transfer siding operate

correctly in conjunction with the main points.

The down starter is constructed from Code 55 bullhead rail, with MSE

components used for arm, platform, operating levers, etc. The model

includes a representation of the operating lever providing the "slot" from

the main line signal box. The signal is controlled by a relay mechanism

based on a modified Maplin power relay.

The up home signal is not fitted, but a design has been prepared for a

dummy colour light signal visible to the operator.

Initially, the station is controlled from a non-interlocked switch panel,

which has been interfaced with Mk2 Tokenless Block equipment, although

signal clearance is not currently dependent on TBS lever lock outputs. The

lever numbers are arbitrary, as the original numbering is not known.

Provision has been made in the design for future slotting of signals at

Pilton from Barnstaple Town SR signal box.

Barnstaple Town L&B signal box was unusual in having windows round all

four sides. The model was constructed from the parts contained in two

Ratio kits, extensively redesigned to represent the prototype. The result

is quite pleasing.

Barnstaple Town Signal Box

The section of the standard gauge side of the

station that is included in the model is purely static, has no points, and

the down starter is merely painted on the backscene, as is the signal box

for the swing bridge over the River Yeo.

Bob Barnard

barnard.bob@btinternet.com

|