|

Building the Gwalior style Mikado

see movie of this loco in action

The Mikado

in its natural habitat.

This saga is about the learning curve one

has to go through when making such radical changes to a stock chassis.

At first I thought I could power the loco from the tender alone.

Experience has shown that this method makes the loco more prone to

derailment and the final evolution uses a powered loco twinned with a

power tender.

When I lived in India, I had

the opportunity of driving a Gwalior Mikado for an entire day. These

magnificent locomotives no longer trundle along the featureless plains

of that state hauling long over-crowded passenger trains. The track has now been

re-gauged to broad and the one or two survivors slowly rust away on

plinths. I wanted to capture this awesome prototype but produce an

English version of it.

I also wanted to show that one can scratch

build brass locos with the minimum of tools in the 'spirit of John

Ahern' who trod this path over half a century ago.

Experience with building the Backwoods

Miniatures Darjeeling Pacific showed that it is impossible to get

sufficient ballast into the locomotive to expect acceptable traction

when using on the demanding County Gate and Cliffhanger layouts.

I wanted to get on with this project while

I had the time but quickly discovered that there was a big delay in

obtaining Romford wheel sets. Fortuitously, the wheel spacings of the

Mikado were identical to that of the Farish class 08 diesel that has

supplied so many successful chassis to our layouts. All I had to do was

just to add one extra wheel!

Thanks to David Churchill, I was lucky

enough to be sent a couple of drawings and works photographs. The

engines gradually evolved in India as is always the case!

First of all I produced a drawing of

the beastie with the tender drawn to fit a powered chassis. I did not

intend to power the locomotive itself but drive it using an N gauge

bo-bo diesel in the tender. The class 08 chassis just had to be

extremely free running.

This drawing was produced so that when

showing on my computer screen, it was exactly the correct size! Other

than a 6ins engineering rule, I have no engineering measuring

instruments. I tend to regard loco building more as animated sculpture

rather than miniature engineering!

A Bachmann loco was purchased from Hattons

a 82051 GE 70 Ton Diesel.

Failed attempt 1

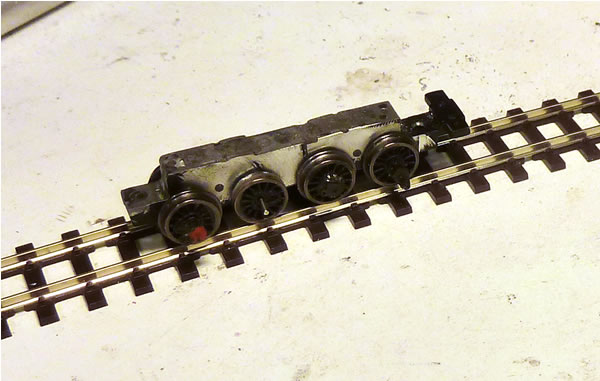

Over time, I had collected a number of dead

class 08 chassis and it was towards the scrap drawer I searched for two

chassis blocks which luckily were available.

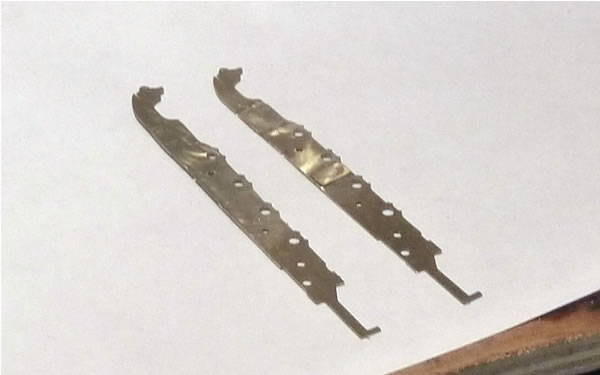

Two sets of frames for the Darjeeling

Pacific were sent to me by Backwoods. If I had known that there was to

be a delay in wheel delivery, I would have built my own frames!

The frames arrived from Backwoods. Two

sets. They were carefully cut in half and resoldered using a simple jig

to ensure everything is in line. The joint was then re-enforced with a

back plate. The front of the chassis was then cut and shortened.

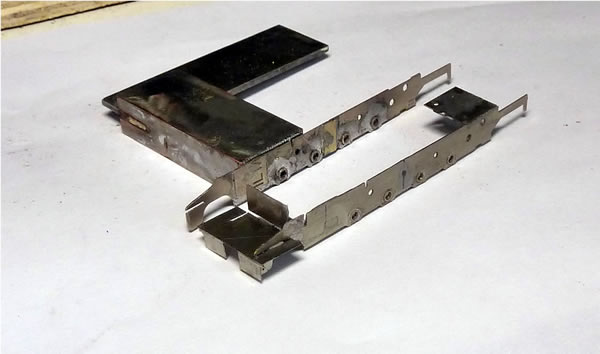

Here one frame is shortened and the other not. A small fillet had to

be added to fill the remains of the second wheel arch

Here, the frames are almost complete

Here, the front buffer beam has been fabricated.

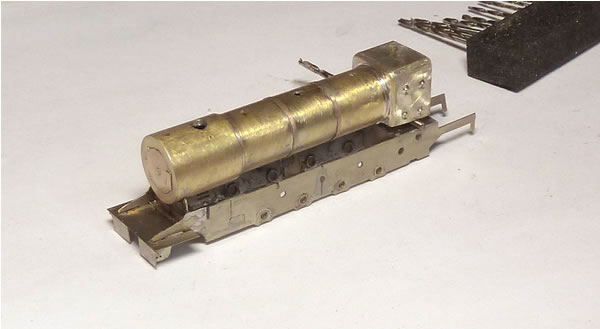

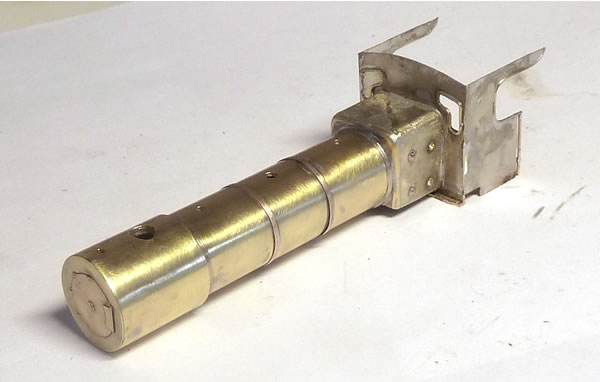

This is the boiler for the beastie. It was formed on an aluminium

marker pen of the right diameter from .2mm brass sheet. The bands are

phosphor bronze strip and the door was an etching I had in stock.

The smokebox is almost complete. I am using Backwoods castings of

dome and chimney from their 'Russell'.

Thick brass rod is formed to make the curve of the firebox front and

is infilled with N/S sheet

The sides are if the firebox are formed with sheet and soldered

carefully to the firebox end. Care is needed to keep everything nice and

square. The whole thing is then cleaned off.

Again, making sure that everything is square and lined up, the firebox

is soldered to the boiler barrel.

The washout plugs are drilled and brass rod soldered in. These will then

be trimmed, and drilled.

After cutting out the cab front, I had the

difficult task of cutting out the spectacles. This was done with various

Dremel grinders. The hardest part was to solder on thin wire for the

spectacle plates and get them to be more or less mirror images of each

other. The annealed wire was then sanded off flat. My trusty engravers

chisel is an essential tool to remove excess solder.

The cab front was then soldered to the boiler making sure everything was

aligned correctly.

The cab sides were

added. I later modified the shape of these.

The cab sides were

added. I later modified the shape of these.

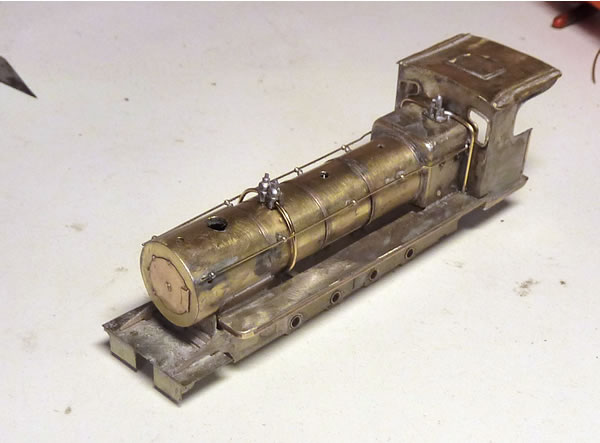

Here, the running and

foot plates are installed. Now for the smokebox support saddle.

The firebox was built as a separate module.

Here, I have made a

simple jig to mark up the positions of the holes to be drilled for the

handrail knobs.

Here, I have made a

simple jig to mark up the positions of the holes to be drilled for the

handrail knobs.

Shown with the firebox loosely in place.

Here plumbing has

begun. I was later able to obtain better lost wax castings for the top

feed from Walthers .

Here plumbing has

begun. I was later able to obtain better lost wax castings for the top

feed from Walthers .

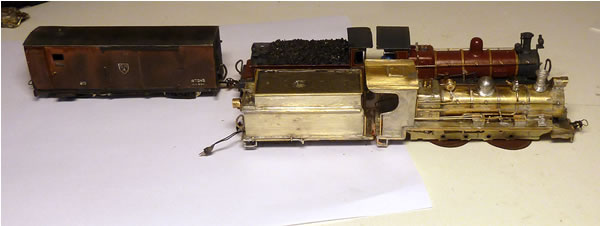

This is the Bachmann

tender unit. The DCC circuit board was replaced by a Digitrax 125

decoder.

The tender is largely complete and I have changed the shape of the cab

sides.

The hinged footplate flap can be clearly seen.

To give the impression of pipe fittings on

the plumbing, I use 3 amp fuse wire, tie it round the wire and touch

with solder, A litte effort with a file and it is done. A couple of

things I made by carving lumps of white metal. For this, I use the

Dremel and engravers' chisels. They are also perfect for removing excess

solder and epoxy from under the fingernails.

The power to a companion car is fed to a socket in the front toolbox

A size comparison with the Darjeeling Pacific. The Gwalior loco is so

large that I had to build at a slightly smaller scale to make sure it

would clear the layout. (3.75mm/1ft)

It was at this time that I got tired of

waiting for the Romford wheels and decided to use a class 08 Farish

chassis from my scrap box!

Here the flanges are being removed using the Dremel and a spare bit of

chassis. The wheel spins round nicely! Care is needed not to overheat

the wheels.

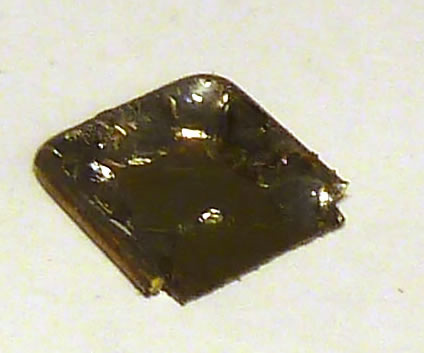

So now the concept is proved, this are

the start of the final crankpins. Wire is soldered onto washers and

cleaned off. They will then be cut to length and glued into place with

superglue.

To minimise drag, I elected to use Roco

valve gear (Roco 09-106-08-1 16295). It has a double slide bar rather

than a single but I have ignored this one!

The hard part is to move from the metal return crank to the plastic

eccentric rod. The eccentric rod terminates as a push-in pin. This had

to be removed and its end drilled. The only effective way to do this is

by using a thin bit of pointed wire which is pushed through while

holding a soldering iron to the wire. Once assembled, a touch of non

drip superglue is used to hold the rod in place.

The driving wheel sets were coated with

Bullfrog Snot traction tyre substitute and this helps make sure the

wheels turn round!

I had to make a new

inside frame front pony truck as I discovered that the one I had built

would foul the cylinders too much on curves.

I had to make a new

inside frame front pony truck as I discovered that the one I had built

would foul the cylinders too much on curves.

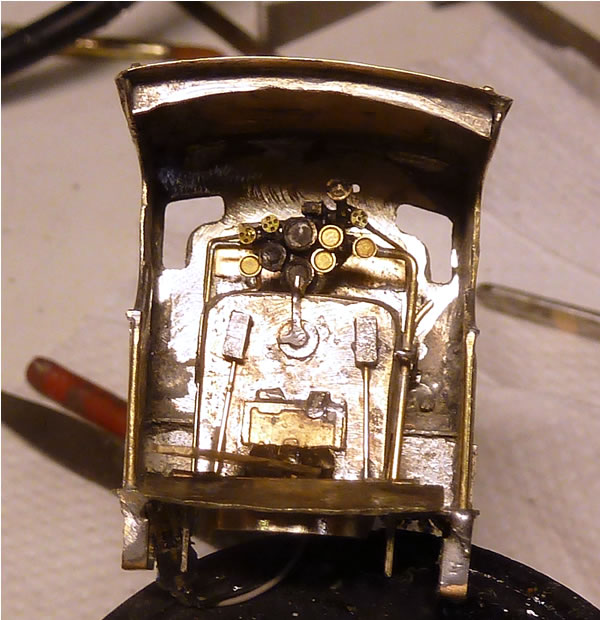

The competed cab detail

The competed cab detail

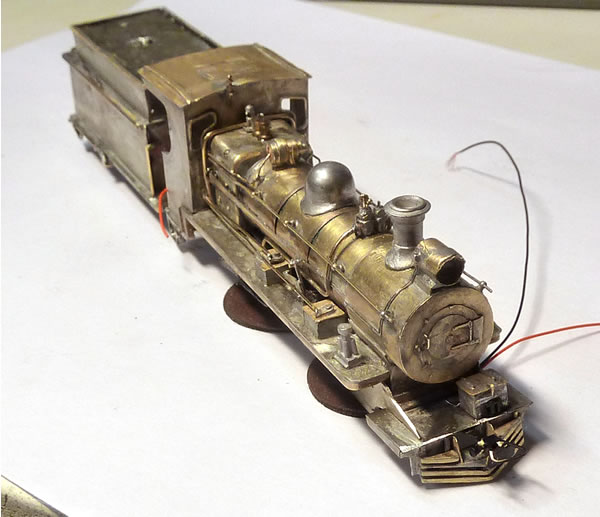

This is how the wiring

is brought to the tender.

This is how the wiring

is brought to the tender.

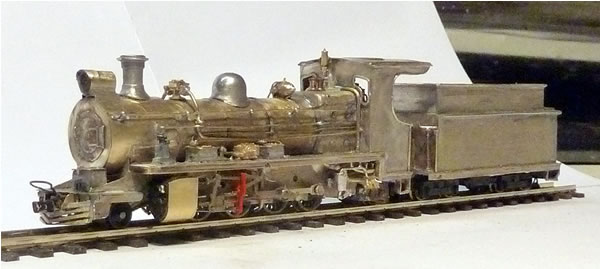

A portrait just before

painting.

A portrait just before

painting.

I used an air eraser to clean the loco and

then sprayed with etching primer and then black. This loco is to be

shown as quite weathered by well looked after.

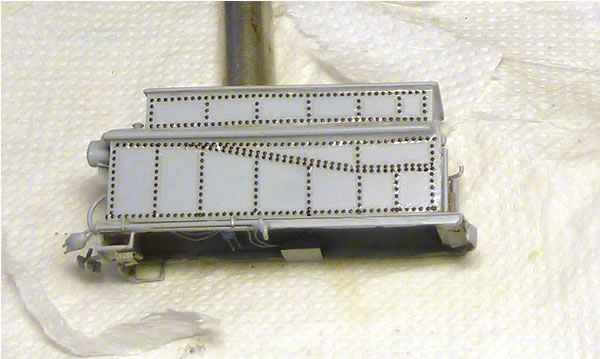

The application of Archer rivets

The application of Archer rivets

I forgot to put on the pony tracks before photographing the loco here!

The dome and chimney cap were gold leafed

by myself and then weathered.

The final parts to make were the ashpan.

This was delayed to make sure they did not foul the pony truck or rails.

A final portrait of the completed

beastie. I am still waiting for the loco crew to arrive!

A final portrait of the completed

beastie. I am still waiting for the loco crew to arrive!

Failed attempt 1 was at least a learning curve

Successful attempt 2

In the end, I built a new chassis which is

powered too and now we have a wonderful locomotive which runs without

any problems at all. The chassis was built again. One cannot expect a

powered tender to push the loco chassis in front in a reliable manner.

Moral. If one gets into modifications, one

is into development and this can be a long and painful process.

With the new powered loco chassis and

lined.

With the new powered loco chassis and

lined.

|