|

DCC explained

I was brought up in the era of

electro-mechanics. You could actually see what was happening in those days

and it made sense. Electronics are wonderful but my general understanding

is about that of ancient tribes observing an eclipse. Circuit boards look

to me like a mad mixture of tiny Liquorice Allsorts and Dolly Mixtures and the

sight of folks making up boards to their own design fills me with admiration.

Conventional model railway controls are based on the well-established

principle of varying the voltage to the track and thus to the motor of the

locomotive. This is usually achieved by a turning a ‘knob’, which actually

controls a potentiometer (some systems use a slider but the principle is

the same). This varies the output voltage to the track and thus to the

motor. To run fast the voltage is increased, to run slowly the voltage is

decreased, to stop the voltage is reduced to zero (or near zero). The

voltage range for OO/HO is usually 0-12 volts DC (direct current). This is

a direct descendant from the battery powered train sets of the 1950s (and

earlier).

This system is sometimes known as analogue control.

To control a single train or loco is simple, connect up and turn the knob.

Running more than one loco on the track however is more difficult but can,

of course, be done by introducing track sections and switches so that each

loco can be switched (isolated) when it is not to move.

Digital control has been around in one form or another for about 30 years.

Older UK modellers will recall the ‘Hornby Zero One’ system from the late

1970s. Modern systems are much more flexible and adaptable but use a

similar principle.

A constant voltage is applied to the track irrespective of the number of

locomotives on the track or where they are. Each locomotive or power unit

is fitted with a ‘decoder’ which acts as the onboard ‘section switch’ or

isolator. The locomotive only moves when its onboard decoder receives the

signal from the controller instructing it to switch on. The decoder also

‘decodes’ the signals from the controller instructing it as to which

direction it is to move in and at what speed. Most decoders also have the

facility to switch on/off loco lights, this can be done whether the loco

is stopped or moving and because the voltage is constant the lights are at

constant brightness once selected.

How does it control the speed when we have constant voltage? The

controller sends instructions to the selected decoder to allow pulses of

the full voltage to pass to the motor. The longer the length of the pulse

(known as its pulse width) and the greater the frequency of the pulse

results in the greater the speed of the motor. This is exactly what

happens with modern diesel and electric locomotives in the prototype

world. At full speed the voltage applied to the motor is in effect full

voltage all of the time.

It is because each decoder only responds to its own instructions (known as

its address) that enables multiple locomotives to work on the same track

and even run in the opposite direction (beware of collisions!).

Decoders for use in locomotives are often described as ‘mobile’ decoders

as decoders are also available for use with point motors and signals;

these are known as ‘stationary’ decoders and these function slightly

differently in that when selected by the controller they switch the full

voltage to the accessory because speed control is not a requirement in

these cases.

A badly running locomotive will still be a badly running locomotive,

miracles do not happen by using DCC however improvements in slow running

are definitely achieved by using DCC. This is because of the difference in

the operating principles explained above. Conventional DC control

permits a low voltage at a small current to pass to the motor when we

want to run slowly. In the event there is any dirt or the motor is

slightly out of balance (most are not balanced) and the voltage applied is

inadequate resulting in the loco stalling.

A DCC equipped loco has the full voltage applied at all times pulsed to

the motor, this results in smoother slow running. In my experience this is

in itself the biggest single advantage of DCC as even flywheel equipped

drives will run even slower under DCC than is possible with conventional

DC control resulting in much more realistic shunting moves.

Clean track and clean loco wheels are essential whatever system is used.

It is claimed that with a DCC system you only need two wires and in

principle this is true, just as with the simplest DC system you only need

two wires. Where DCC results in real savings in the complexity of the

layout wiring is where track layouts are at their most complicated AND

where you want to run more than one loco at a time.

Take for example a passenger terminal with adjacent goods yard accessed

from the same main line track with multiple point work, crossovers etc. In

a conventional DC wired layout you would need to install ‘cab control’,

switches, and isolated sections in order to work a passenger train and

shunt at the same time. With a DCC wired layout there are two wires taken

to each feed position, no switches, cab control or isolated sections.

Any loco can run at any time to any point on the layout.

|

Easier Multiple

Controller Control |

With Conventional DC control you can wire in two controllers using cab

control and section switches but it gets very complicated when three or

more controllers are required.

DCC controllers allow you to just plug in another handset, which has all

of the facilities of the original. It may be necessary, with some systems,

to purchase ‘extension plates’ but all but the basic units will allow at

least two control handsets to be plugged in. Using ‘extension plates’ does

however have the advantage of enabling the additional handsets to be

mounted away from the base control unit but retaining all control

features, an especial advantage on larger layouts or where there is a

shunting area remotely located.

Except for the very basic DCC control systems all will allow the operator

to unplug the handset and move to another plug in point and at the same

time the locos are still running unaffected. This can be a very useful

feature on larger layouts and even on smaller ones when two operators have

managed to get their cables twisted! This is a

feature our American cousins use extensively on their (usually) large (by

UK terms huge) layouts allowing train operators to actually follow their

train all around the layout. There are wireless DCC controllers now

readily available.

|

Correct operation of

lights |

DCC decoders are quoted as being one function, two function or more. This

can be confusing as what constitutes a function? In the case of a

locomotive that has running lights fitted that change when direction is

changed a two function decoder is required to make the lights work

properly. This is the one instance where conventional DC beats DCC!

In a

DC loco there is a rectifier (diode) circuit that prevents the wrong

lights coming on in the wrong direction of running, in DCC this needs a

signal for forward and one for reverse. However, decoders can be programmed

not only to switch the correct lights for each direction but can also dim

the lights (even flash) where appropriate – try that with DC control! A

one-function decoder can only switch on/off the

lights irrespective of direction. A loco parked in the platform waiting to

depart can have the correct headlights at the appropriate brightness even

when stationary. This can be done with DC but with additional

complications, it is standard with DCC.

Not everyone’s cup of tea but excites some folks. Personally

sound is growing on me provided that it is not turned full on. Sound has a place.

This results in the small

speakers not being ‘over amplified’ resulting in distortion. Factory

fitted sound systems are despatched set at full volume (that’s how they

are tested) and most purchasers do not realise that they can adjust them –

read the manual! It is easier to adjust sound, use it and enjoy it with DCC because the sound system can be adjusted simply by altering a CV (it's

easier to do than explain how to do it ! Just follow the manual.) DC

versions are now coming onto the market but these suffer because they are

not easily adjusted (if at all).

Sound in the model railway world is an interesting feature but we must

recognise that the laws of physics are still valid. Sound quality from a

speaker depends on the size of the speaker and the quality of the signal.

In N gauge and OO/HO we have to accept that speakers have to be tiny and

therefore cannot have the Bass – Treble qualities of our domestic sound

systems; accept that and you will not be disappointed BUT hear it before

you buy it whenever you can.

Locomotives running on DC are about as clever

as a bag of hammers. Chipped, locos are more intelligent than

George Bush and enormously more so than Sarah Palin! The new

chips are really very small and we were advised to choose the latest

Digitrax offering. The new Digitrax DZ 125 chip is similar in

size to the Lenz silver mini. This chip,

despite the instructions that come with it, is enabled for back EMF (BEMF)

(called 'scalable speed stabilisation' by the Yanks).

DZ 125

This offers better slow speed running and

also compensates for grades (a bit like cruise control).

At long last, the chips arrived and the exacting job of fitting them to our locomotives began. It was

necessary to virtually rebuild some of the older engines, and installation

into the L&B units was far from easy. Great care is needed to ensure that

there are no shorts in the system.

Chips can actually control other functions

too such as directional lighting. We have installed this on a few units

and it works very well indeed. The large amount of wiring needed to do

this raises challenges when working with such tiny rolling stock. I do

intend to fit sound to one unit, just for the hell of it!

The generic manual for these Digitrax chips

can be found

here

and the specific manual for the DZ125,

here

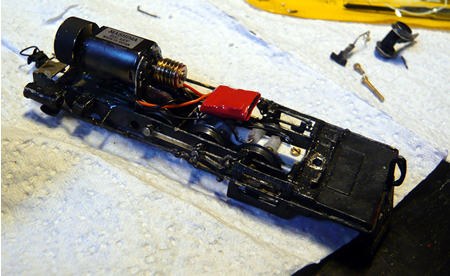

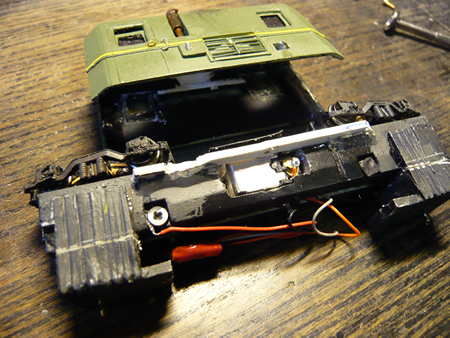

chip fitted to the

chassis of 'Taw' - click on image to enlarge

The motor unit of

the railcar converted. The part of the chassis which contacted the brushes had to be milled

away and the wires then attached to the brushes - click on image to enlarge

Once the Digitrax Zephyr outfit was

delivered, it was installed into the viaduct section of the model. The

main control box was fitted into a recess cut into the front of the

baseboard. This box is held in place with Velcro. In order to programme

locos, it is necessary to have a programming track...two leads come from

the control box to do this. We felt that this was another complication, so

the harbour branch of the viaduct section is fed through a double pole, double throw

switch to provide either track power or programming.

The leads to the UP5 remote sockets daisy

chain from the main controller. It is transferred from one panel to the

next using 8 pin DIN plugs/sockets. These also carry the track power.

the main control box

fitted. Below is the switch to track for programming or power. The DIN

socket will feed to the harbour section

The box was 'lit up' and I have to say we

quite quickly got the hang of it. All the locos now had their numbers and

can be programmed to perform as required up to a point.

DCC promises to offer all

the characteristics that I required and there is no doubt you can programme each engine to do most things.

The programming of a loco

depends on altering a vast number of parameters. These are called CVs and

there are well over one hundred of them. These all have to fiddled with on

a programming track while your supper goes cold. In my opinion, a lot more

has to be devised to make the system user friendly.

I can honestly say that I

have not managed to get back EMF to work and I wonder if I shall ever be

able to properly programme these little engines.

DCC manuals seem to have been written by electronic nerds for

electronic nerds (or USA speak). I have to say that Lenz scores slightly

better in this respect, but Digitrax and NCE just make my eyes roll. Some

of the information is actually wrong and there is no logic (understandable

to British and French) to the way the manual is compiled.

There are a number of

forums available where help is at hand and this does ease the situation.

Thanks to some good

friends who are 'in to all of this' we hope to be able to publish here the

generalised programming necessary to get narrow gauge locos to run as they

should.

Bitter experience has

shown us that it is a very bad idea to use Peco point motors or others

requiring a CDU. In 20/20 hindsight, I would have fitted Tortoise

throughout.

Example:  Circuit symbol:

Circuit symbol:

Function

LEDs emit light when an electric current

passes through them.

Connecting and soldering

LEDs must be connected the correct way round, the diagram may be labelled

a or + for anode and k or - for cathode (yes,

it really is k, not c, for cathode!). The cathode is the short lead and

there may be a slight flat on the body of round LEDs. If you can see

inside the LED the cathode is the larger electrode (but this is not an

official identification method).

LEDs must be connected the correct way round, the diagram may be labelled

a or + for anode and k or - for cathode (yes,

it really is k, not c, for cathode!). The cathode is the short lead and

there may be a slight flat on the body of round LEDs. If you can see

inside the LED the cathode is the larger electrode (but this is not an

official identification method).

LEDs can be damaged by

heat when soldering, but the risk is small unless you are very slow. No

special precautions are needed for soldering most LEDs.

Testing an LED

Never

connect an LED directly to a battery or power supply!

It will be destroyed almost instantly because too much current will pass

through and burn it out.

LEDs must have a resistor

in series to limit the current to a safe value, for quick testing purposes

a 1k resistor is suitable for most LEDs if your supply voltage is 12V or less.

Remember to connect the LED the correct way round!

resistor is suitable for most LEDs if your supply voltage is 12V or less.

Remember to connect the LED the correct way round!

connecting to the chip

As a general rule, the

anode, (the longer prong) is commoned and connected to the blue wire of

the chip and the white and yellow wires go to the cathode.

|