|

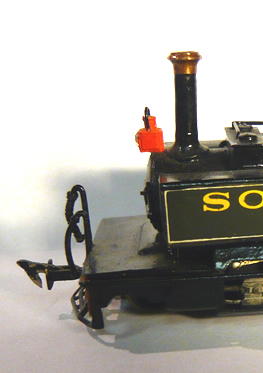

Couplings, cowcatchers and pickups

doing it properly - one of Bob Barnard's locos fitted with Meridian

couplings

It has been said that the overhangs on L&B

Manning Wardles are actually greater than my stomach's. This does mean

that there are some serious difficulties in navigating fixed couplings

around the rather standard 12" radius curves of the 009 layout. The purist

will still go with scale couplings, which can be purchased from Meridian

Models. The problem is actually using them. Reaching over a layout with

a pointy stick and a shaky hand to lift up chopper couplings is not

everyone's idea of fun.

At County Gate, we have opted for the

Greenwich couplings, which look a bit like narrow gauge ones and offer

automatic coupling and uncoupling with magnets hidden between the rails.

There are a number of ways to make these

work. I shall first describe the method we use on our Backwoods MWs.

click image to enlarge

The front coupling does not have a lifting

loop and therefore, the cowcatcher can remain intact. We just extend the

buffer beam slot a little to allow for movement. We use fine steel

wire. Form a loop at one end and where best, bend a crank to bring the

coupling to the correct height. The Greenwich Coupling is cut short and

soldered to the end of the wire. Easy peasy.

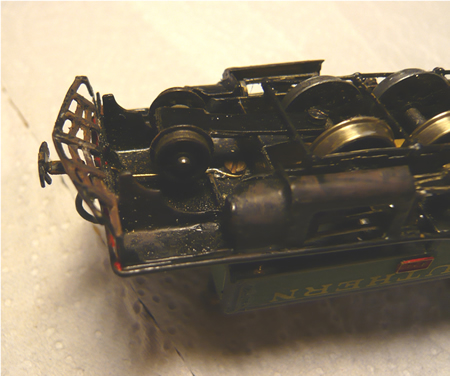

The rear is a tad more demanding.

click image to enlarge

We first have to solder a nut to the chassis

to take the fixing screw. Don't forget that the trick to solder nuts

without getting solder into the threads is to jam a cocktail stick down

the nut! The lifting loop of the Greenwich does need a lot of room, and we

are forced to remove the centre of the cowcatcher as shown. The

system does work very well although care has to be taken not to bend them

during handling. The spring of the wire offers the perfect 'give' around

corners.

The only loco that we are able to use fixed

couplings with is the Garratt which is articulated and with minimal

overhangs.

Some

locos do not offer a long enough length of empty chassis to

accommodate a spring wire. A

case in point would be the recently built 'Mad Mallet'.

A cruciform wire is soldered to the coupling

which retains two Bemo coupling springs. There you have it, a perfect

sprung coupling.

Here, the coupling is placed on a wire pivot.

It is retained in placed with a small washer. Two small sheets of brass

are soldered to the rear of the buffer beam to make the coupling box. In

some cases, the box would be formed by the existing chassis fitted to the

loco.

Another method I use is good for loco

couplings.

this was enough to derail

the following car

In an ideal world, one would use scale radii

on turnouts. Sadly, if this had been done at County Gate, we would never

have fitted everything in.

Now the worst offender for coupling lock is

our Baldwin 'Lyn' whose overhangs exceed even those of Jordan.

We now use a very fine spring wire which

slides in a small hole in a bracket soldered onto the cross member just

aft of the rear driver to centralise the coupling. This immensely improves

the situation but at a couple of tight double reverse curves Lyn was still

pulling the following car off the track. Our trains are intended to be

fixed consists, so we have been able to modify the coupling of the

adjacent bogie van.

new 'Lyn' coupling arrangement - click image to enlarge

The van coupling is free pivoting under the

bogie and centralised by a long spring wire

The coupling height of our rolling stock goes

back to the locomotives made by me in the early 1970s. For us it was 5.5mm

to the top of the buffer plate. It seems that this has subsequently become

a bit of a standard height, but no thanks to me! I have a short section of

track glued onto foam card with a 'buffer' glued to one end. Into the

buffer is glued a Greenwich coupler at the correct height. All stock

is visually checked against this.

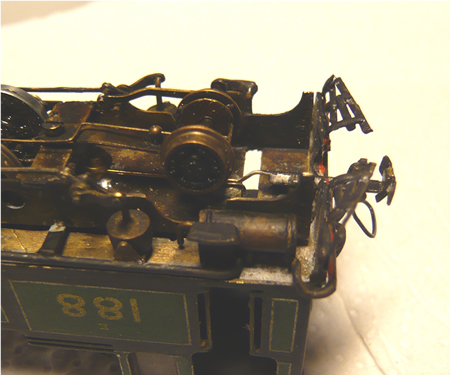

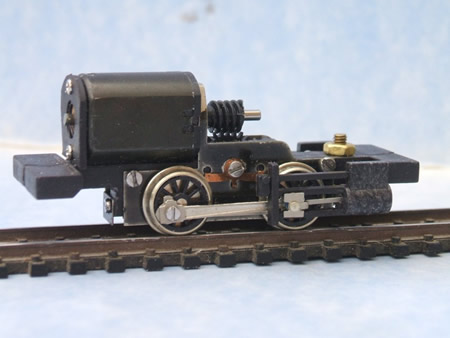

The Backwoods instructions suggest that the

electrical pickup be made using the phosphor bronze wire supplied

contacting the wheel treads. This is in principle a very bad methodology

because dirt picked up from the rails will gradually diminish

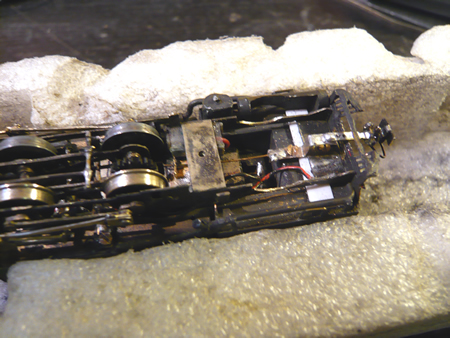

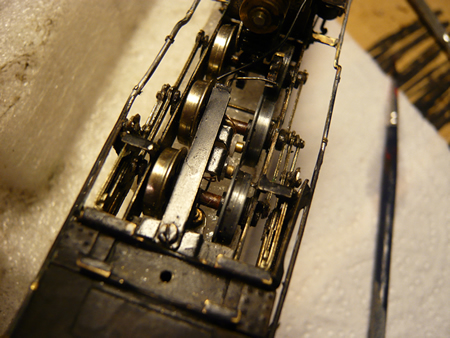

conductivity. Our chassis builder, Peter Wallace developed a different method.

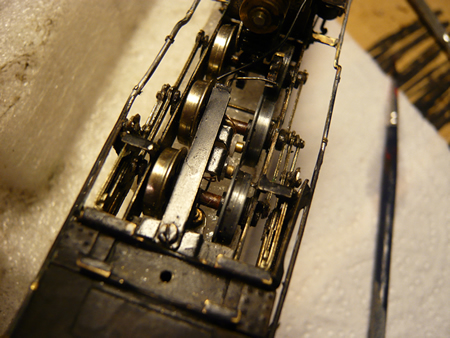

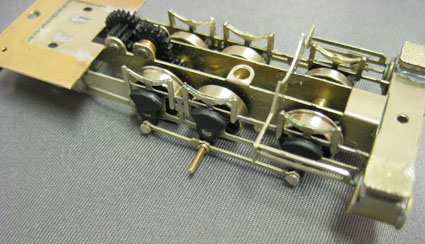

click image to enlarge

With space at a premium he solved the

problem by having one sprung wire contacting the flange, while the other

wheels had power picked up from the rear of the rims using spring

plungers. Sadly, after many hours running, the plungers began to fail and

have since been replaced with phosphor bronze sprung wire pickups acting

on the back of the wheels.

|

how

is the electricity collected from the wheels? |

Without question, the worst place to collect

the power is through contacts acting on the wheel treads. Dirt will

inevitably collect on the treads and transfer to the collectors with the

result that sooner, rather than later, the loco will stall. Far better to

collect the power from contacts acting on the wheel rims or back of the

wheels. Sprung collectors are usual but very small plunger collectors are

available and are excellent.

Most modern chassis have insulated driving

wheels on one side only while the entire chassis is live with the opposite

polarity. This is now standard practice with say, Backwoods chassis. This

can have its drawbacks too. Great care is needed to make sure that pony

truck wheels can never touch the chassis.

Worse, some methods of installing couplings

means that they are live to the chassis. Unless you get it right, double

heading can cause a dead short. This means that you must always set up

your loco with a common polarity and never turn them around.

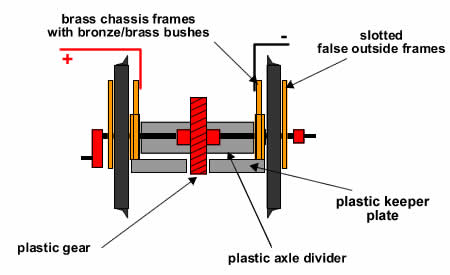

Another solution is the 'split chassis'

system. Here, the current is transferred through the axleboxes but there

are problems when scratch building to prevent the 'wrong bits of the loco

touching live bits' and thus shorting out. The axles of a full split

chassis system must also have an electrical break in the middle of the

axles. Thank goodness for Plasticard and epoxy glues!

The advantage of the split chassis is that

there is no resistance due to collectors acting on the wheels. The spacers

between the chassis frames also have to be insulating. The drawing below

is how I built the chassis for my K1 Garratt. For this type of chassis, I

use a conducting lubricant.

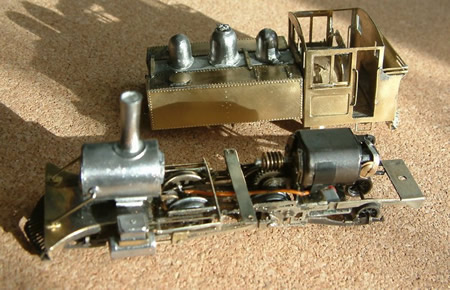

this Manning Wardle chassis has a 'live' side and plunger pickups on the

other

re-engineered Backwoods Baldwin chassis

One advantage of DC operation is that

electronic track cleaners can be employed. Quite often, a small resistance

between the wheels and rail are blown away with a micro jolt of high

voltage (they are also quite good for keeping your cat off the track).

If you are running DCC, you can programme an

additional start current which can often help.

Some products can be used on the track such a

Rail Zip or indeed a soft woodworking pencil. There can be wheel slipping

on gradients using some of these products.

If at all possible, flywheels should be built

into the model. Their size is going to be small to fit in the average 009

body but is often sufficient to help with smooth running and help the loco

through dead spots. Sadly, space just cannot be found in all locos, such

as in the Backwoods 'Lyn' shown above.

We all expect good slow running these days.

This will mean a gear train with accurate meshing of gears and good

bearings are an essential part of the formula. Some Backwood kits have the

motor worm drive slightly offset. While this may work, I have found that

excessive wear can take place.

Some specialist chassis are constructed in

such a way that it is almost impossible to take them apart to effect

repairs. The standard Backwoods chassis are exceptionally difficult for

instance. If at all possible, assume that everything will eventually wear

out and need replacing.

Some chassis designs are simply asking to

wear out due to their construction.

Firstly, let's look at the much vaunted

expensive Roco outside frame chassis.

click on image to enlarge

the Roco 'rip-off'

Here, the axles are not in bushes but make

point contact with the die cast chassis. Very quickly there is wear and

the loco will no longer run properly. The plastic keeper plate also slowly

wears down. On top of all this, the Mashima motors supplied in the

loco very quickly develop a very rough spot when slow running. This is

another thing to look out for. These days, if at all possible, I remove

motors and run them light. In my view, there just should not be any rough

spots at all.

For reliable running, axles must be fitted in

proper bushes in brass or better still, bronze.

a properly bushed chassis by Victors Models (Sandy River No 19)

Equally, coupling rods and crank pins will

wear. This is particularly the case with chassis that are driven through

one axle as is the case with the chassis shown above. I now favour hard

steel crank pins and bronze bushes sweated into the coupling rods. If you

think this is a tad over the top, our first Backwoods Manning Wardle wore

out its crank pins and rods after 20 hours of operation.

This leads us on to the next issue. If only

one axle is driven, it is far far better to drive the centre axle in a six

coupled unit rather than an end one, as shown above. There is far less

binding and likelihood of wear. In my view, the best solution is to drive

all coupled wheels.

The Early Lilliput chassis did this and will

run forever given simple maintenance. True, they run too fast and the

motor is not the best but the coupling rods do not do any work so they can

be reduced to scale size with no concerns. My Baldwin, which has such a

chassis and is fitted with scale sized rods, ran 24/7 for a year in a shop

window. It still runs great now!

early Lilliput chassis

One chassis which potentially fulfils all the

requirements is the new

N Drive

Productions unit. They even

promise to offer them with outside frames. True, no

valve gear comes with it, but this is easy enough to add, using a fret

available from Backwoods Miniatures at £18. The drawback is that at

present, their construction is a part time job and as they become more

popular there might be some delivery delay. Hopefully he will find ways of

increasing production.

N Drive

Productions 6 coupled outside

frame chassis

0-4-0 chassis by

N Drive

Productions (£42)

I have always tested my chassis for 8 hours

running forwards and a further eight backwards, If any sign of wear showed

after this ordeal, the design would be re-engineered. That is, until I

bought the Roco chassis, which I assumed had been previously rigorously

tested. How wrong I was and the whole exercise has cost me hours of work

and £400!

By the way, it is worth keeping logbooks for

your locos so you can record the hours they have run.

There are, of course, those who just like to

collect locos...lots of them. But for those who are building a layout and

want their locos to look as good as possible, is it not time to take a

long hard look at the quality of running chassis? Costs are coming down

but there is no doubt that 'proper' locos are going to be more expensive.

What would you rather have, numerous toy trains or fewer proper models?

I have got thoroughly fed up with 009 bogies

and wheels supplied in kits. They are not very free running, often

inaccurate and if one is able to get them working, they can be very

delicate.

Mass produced N gauge equipment is, on the

other hand, very reliable. Simple solution...use N gauge gear. Our Lynton

and Barnstaple narrow gauge rolling stock sits on the rails rather like

sausage dogs - you really can't see the undercarriage! I hear anguished

purists bemoaning the use of such gear, but they are often same folks who

spend a lot of their time putting things back on the rails!

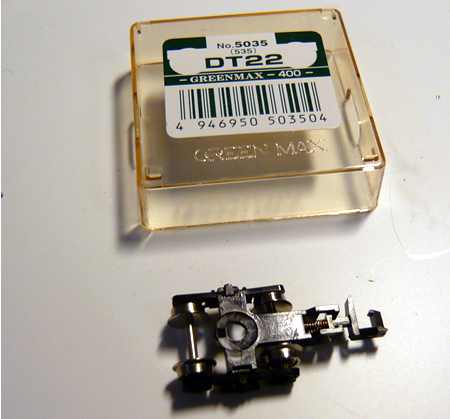

I have selected bogies produced by Green Max.

These are getting hard to find these days but are still available if you

Googler for them. We use DT 22 bogies for goods and DT 16

for coaching stock (or equivalents). The wheel bases are a bit shorter, which allows one to

place the bogies between the frames, where they are supposed to be, and

still get sufficient movement for 12" radius turnouts. At present,

there seems to be supply difficulties with Greenmax.

I have rarely found a Green Max wheel out of

'back to back' but I do check every one with a gauge. The additional

advantage of Greenmax wheels is that only one wheel is insulated so they

can also be used for current collection. I just pull out the knuckle

coupling and glue in a Greenwich version.

Green Max

goods bogie

|

getting power to the locos |

Many of our locos have small wheels and not

enough of them to be able to reliably collect current at all time to run.

In order to get more wheels to supply current, pony wheels can be used as

well as the drivers. The simplest method is to use just one wheel each

pony truck. With Greenmax wheels, this is simple.

Another method is to use the adjacent

wagon/coach as a current collector. Often, locos remain in a fixed consist

so under these circumstances this is a very good option. All our main line

trains that run under automation are connected to companion cars and they

almost never stall. We stick copper tape on the inside of one bogie side

(opposite side for the other bogie) and link up with thin flexible

multistrand wire to connectors to the loco. A dap of Copperslip grease

in the bearing hole will ensure good electrical contact.

self adhesive copper tape

attached to one side of a bogie. The pickup wire can be seen.

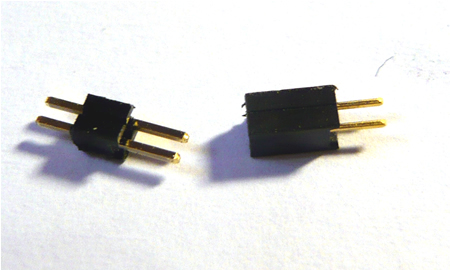

The connectors used are supplied by Express

models. Another advantage is that is is very easy to test a loco on DCC by

just plugging in with a lead.

Once you have soldered on the correct wires,

you will need to encase the joint in epoxy, otherwise the joint will break

in time.

The choice of wire as connectors is

difficult. They do have to be very soft and flexible. The best is that

supplied by DCC Supplies. They use it for DCC chips.

The plugs are inserted with tweezers and are

marked with a small spot of paint to ensure correct polarity.

micro connectors supplied by Express

Models

'Lyn' and her best friend!

I always advocate using 'companion cars'

connected to locos that run with fixed consists. The additional current

collection makes these trains almost 100% reliable. The problem at times

is that the bogies of the companion car are far better at collecting

current than the rigid chassis of the locos themselves. After a period of

operation, the locos become very reluctant to operate on their own.

Careful cleaning is needed and after a little coaxing, they will begin to

run again. I always let them travel a few circuits in both directions on

their own before reattaching to the companion car.

Despite best efforts, occasionally we find a

piece of rolling stock that just will not stay on the rails.

-

Check back to back

measurements on all wheels

-

Is there a lump of say,

glue, attached to a wheel tread?

-

Are the couplings

sticking against the body or not giving sufficient movement side to side

where there are derailments?

-

If bogies, is there

enough room for them to move sufficiently?

-

Is the stock heavy

enough?

-

Are the wheel sets/bogies

in line? Check the vehicle on a sheet of glass

If none of these things

work sell the railway!

|