|

the 'Glenthorne Rose'

The harbour scene has been a challenge as it

is all to easy to finish up with the modelling cliché of the cute

folkloresque harbour with the inevitable Clyde Puffer. It quickly became

clear that the collier would have to be scratch built. There is nothing

like it available as a kit, and H0 scale would just not work as the vessel

is in the foreground.

I wanted a flush riveted iron hull with

straight stem and fantail stern and three islands. Glenthorne Rose is an

amalgam of the typical features of this type of vessel built at the end of

the nineteenth century. I wanted the plates to be bashed and buckled after

a very hard life, and one hold being opened, showing how this is done. The

computer generated drawing below shows just what I wish to achieve.

rust bucket 'Glenthorne Rose'

(original computer drawing)

the completed model

I checked beam to waterline length to be typical of

the period and mugged up a bit on ship building techniques of the period.

The shape of the hull was first cut out of 4mm ply

and the second layer also cut. Once satisfied with the shape, in particular the

start of the fantail, the bottom layer was prepared for fastening to the

baseboard. The ply edges were covered in epoxy resin and once cured, very thin

Plasticard sheet was cut into plates and fastened to the hull using plastic

weld. a more generous application of plastic weld results in the plates settling

down nicely onto their overlaps. Remember to start plating at the stern and work

forward.

The plates were then primed and sprayed black and

rust worked into the plate joints. They were then 'treated for seaweed' in the

same manner as the harbour walls, (little on the bows though). Once glued into

place, I used self adhesive book binding tape to make the dam at the front of

the harbour water (this

is quite rigid and is easy to fit) and poured in the West epoxy resin. At the

right moment, a gentle swell was worked into water and there we have it! The

baseboard can now be sanded, painted and varnished.

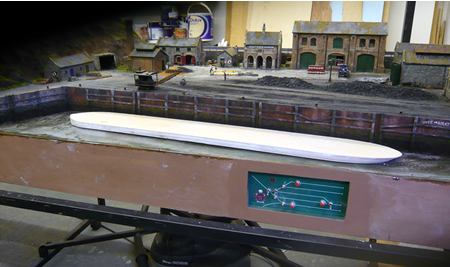

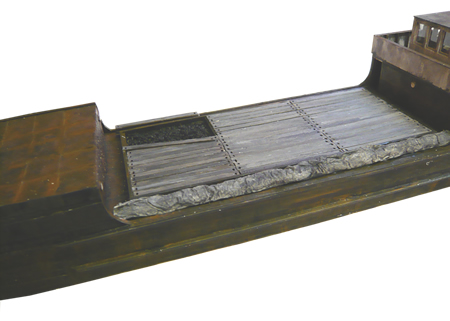

the first two ply layers (a bit warped at this point!) - click on image to

enlarge

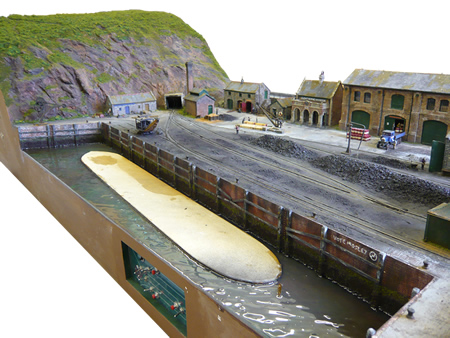

The base is now plated and attached to the baseboard and a very mild swell added

in resin - click on image to enlarge

The main part of the hull was made using two wood

lengths for the hull sides and the bow and stern carved in plaster. Carpet tacks

were tapped into the ply at each end to ensure that the plaster adhered.

The hull was then covered in thin Plasticard sheet

cut to the complete hull shape. This was attached using epoxy glue.

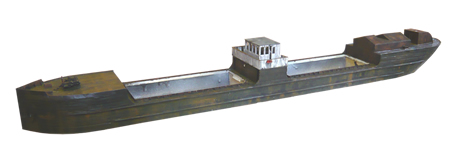

the main hull is complete and ready for

plating - click on image to enlarge

Very thin

Plasticard sheet was cut into plates and fastened to the hull using plastic

weld. a more generous application of plastic weld results in the plates settling

down nicely onto their overlaps. Remember to start plating at the stern and work

forward. While the plates are still soft they can be distressed to taste.

The gouged and battered plating and anchor, (carved in plastic)

- click on image to enlarge

hull painted

- click on image to enlarge

click on image to enlarge

A lot of trouble was taken to get the hull

well and truly bashed.

click on image to enlarge

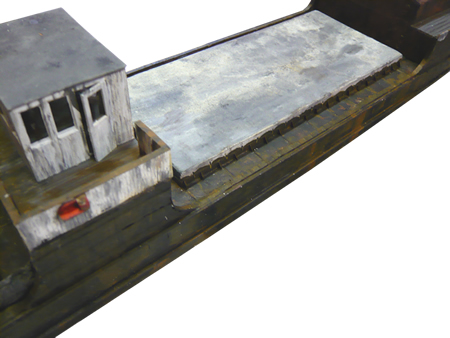

I have never seen a model of a freighter

where the hold tarps are being opened up, so this was my chance. The rear

hold is still fastened down and the front has had the tarp rolled off and

the boards are being removed.

click on image to enlarge

click on image to enlarge

here, someone has started to paint! - click on image to enlarge

The railings are complete and the spars being rigged - click on image to enlarge

Completed ship ready for baseboard. The ship is held in place by 2 screws - click on image to enlarge

click on image to enlarge

click on image to enlarge

|

a few

notes on construction |

The entire superstructure was made using 1/16"

Plasticard. The rivets were punched through very thin Plasticard which was then

epoxied onto the base form. If distressing was required, Plastic Weld was used

instead! The spars were made with brass tube and wire. Everything was soldered

up, including all the railings which were made of wire. The rigging was made

from fuse wire. For best results, the main standing rigging should be brought

through the hull and tensioned from below; this way, adjustments can be made.

I often notice model boats and ships which are

incorrectly moored.

The diagram above shows the basic principle of

tying up. Because the ship/boat will move with the swell, the lines, after being

attached to cleats, pass through fairleads that prevent damage to the ship and

line. The spring lines are needed to prevent the ship from moving fore and aft

alongside. I notice that these are often omitted.

the 'Rose' alongside showing springers

|