|

the evolution of bridge design

This article may seem a bit over the top for

railway modellers but if a freelance railway be being built, it may be of

use to understand how bridge structures have evolved over the years.

The historical development of bridges is the

field which best illustrates the progress of structural engineering from

ancient times up to the present century. In particular the development in

steel bridges shows how design has moved from intuition to advanced

structural analysis.

When

the new material, iron, and later steel, was ready for use in larger

structures there already existed a quite highly developed technology in

bridge building, namely for bridges in timber and bridges in stone.

Thus, the building of

steel bridges was founded at the beginning on the then well-tried

principles and construction methods of timber and stone bridges. Stone

bridges provided the arch type while wooden bridges demonstrated mainly

fine-structured trusses. According to the typical material properties of

cast iron - the first type of iron available - iron bridges were first

built as arches. Later, when steel was available, which is capable of

acting in tension, various structural systems were developed on the basis

of the principles of wooden trusses.

Arches transfer

distributed vertical loads to the foundation mainly by compression. Due to

the specific material properties of masonry they are basically the

appropriate form of structure for stone bridges.

Pont du Gard built in 18

BC

In the Middle Ages the

construction of flat arches was developed in order to build lighter

bridges and larger spans.

"Pont de la Concorde" in Paris of 1791

In 1779 Abraham Darby III,

an English iron founder, succeeded in building the first iron bridge in

Coalbrookdale. The Coalbrookdale Bridge was constructed as an arch

bridge like the examples in stone before, however, the arch was structured

in 5 light ribs following the constructional principles of wooden

structures. The bridge has a span of about 30 m and is still in use. Such

cast iron bridges soon became common structures in Britain and were

exported to other countries.

Another method used cast iron tubes for

the compression member of the arch. This economical system was widely

used, an excellent example being the "Pont du Caroussel" in Paris, which

was built by Polonceau in 1839 with three spans of 48m each.

"Pont du Caroussel" in Paris

The largest cast iron arch

ever built was the "Southwark Bridge" by John Rennie over the Thames in

London (1819) with a span of 73 m

The "Mississippi Bridge"

in St. Louis was built in 1874 by J.B. Eads. He used tubular members

partly of iron and partly of steel to form the latticed arch of 159 m in

span. It was the first bridge he built and surprisingly became the largest

arch span in the world.

Gustave Eiffel also used

trussed construction. He was the first engineer to develop the preparation

of steelwork design up to full detailing and drawing of every element or

single rivet. His most

beautiful bridge was the "Viaduc de Garabit" in the South of France, built

in 1884 with a span of 165 m .

Viaduc de Garabit

With the development of

steel the size of structures increased. The largest arch spans were built

in the years up to 1930

the "Bayonne Bridge" in

New Jersey by O.H. Ammann in 1931 with a span of 504 m

the "Sydney Harbour

Bridge" by R. Freeman in 1932 with a span of 503 m.

|

beam

structures including trusses and plate/box girder

bridges |

iron in the first period of

bridge building could only be used in compression. It was not until more

than fifty years later when larger bridge structures were built that

bending structures were adopted using the newly developed wrought iron,

and later steel, which were capable of acting in tension as well. At that

time there already existed a highly developed technology of building such

bridges in timber, in particular trusses of various shapes and systems.

Since constructional steelwork at the start used a great deal of this

knowledge a short overview is given below of the development of wooden

bridges.

The heyday of bridge

building in timber took place in the second half of the 18th century. From that time on the development of

wooden bridges moved to the USA, where - due to the lack of trained

carpenters - simplified structures came into use. Standardized and

prefabricated elements and simple connections were made with unskilled

labour, but nevertheless produced large bridge structures, especially for

the railways. The main types of bridges resulting were trestle bridges and

truss bridges.

The latter - among others

- comprised patented systems like the widely used crosswise-pretensioned

truss girder.

During the first half of

the 19th century, steel bridges were frequently designed as trusses,

particularly in the USA. This was mainly due to their economical

load-carrying behaviour. However, in Europe this same development was

interrupted by a short period, when tubular bridges were made of large

plated girders.

|

development of plated girders - Robert Stephenson |

To cross the Menai Strait, Stephenson decided to build a bridge in the

shape of two rectangular tubes (each 4,4 m wide and 9 m deep) through

which the two railway tracks ran.

The Britannia

bridge carried the railway traffic well for 120 years until 1970 when it

was damaged by a fire.

A second bridge of this

type, but with somewhat smaller spans, was built by Stephenson over the

River Conway at the same time.

|

truss

bridges (parallel girders) |

Latticed

girders were copied in steel, resulting in fine-mesh lattice

girders since flat sections can resist compression forces only with

reduced buckling length.

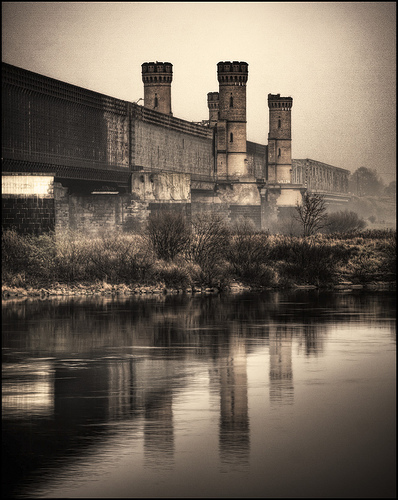

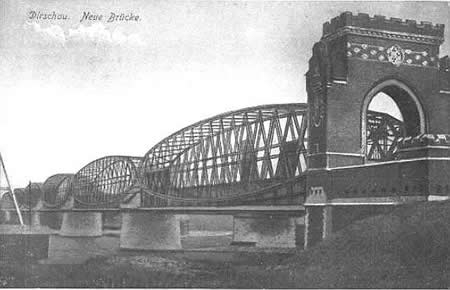

The largest beam bridge of

this type in Europe, the "Dirschau Bridge" over the River Weichsel (Vistula)

in Germany, was completed in 1857.

The first iron truss

bridge to be made of struts was the "Grandfey Viaduct" near Fribourg in

Switzerland, opened in 1862. Although similar in type to the

wooden trestle viaducts in the USA, it was the first true modern trussed

girder with appropriate compressive members.

A typical truss bridge of

that time was the Danube Bridge near Stadlau in Vienna. It was built in

1870 as a continuous beam with five spans of 80 m each. The picture shows

the process of launching.

Eiffel built a great

number of truss bridges for the railway in France and Portugal. Eiffel's largest bridge of this type was

the bridge over the Tardes near Evaux, with a main span of 105 m (72 + 105

+ 72 m), built in the same period.

Truss bridges of the

parallel-girder type were built in great variety, especially for the

railways in Europe. The Rhine Bridge near Maxau in Germany, built in 1938,

is a good example.

Pauli girder, Saltash

Bridge, Lohse girder (fish-belly or parabolic

girders)

The objective of obtaining

an optimum distribution forces in trusses led to new shapes

of girders, the parabolic-truss girder with a curved upper chord and the

fish-belly type girder with both chords curved in opposite directions.

The first Pauli girder,

built in 1857, was the railway bridge over the Isar near Grob hesselohe

(Germany) with spans of 53 m .

A gigantic bridge of the

fish-belly type was the "Saltash Railway Bridge" near Plymouth, also known

as the "Royal Albert Bridge". Completed in 1859 and having two spans of

139 m each. The builder was Isambard Kingdom

Brunel.

Fish-belly type girders of

Pauli's design had a lot of constructional advantages and were used in

German bridges again and again. For example the second "Dirschau Bridge"

over the River Vistula had six spans of

131 m.

A similar type of bridge

was the double bow girder bridge, called "Lohse Girder" after its

originator. The structural

system, somewhere in between the fish-belly type and the tied-arch type,

consisted of two trussed chords connected with vertical members. The most

important examples are the five Elbe Bridges near Hamburg built in the

period from 1872 - 1892.

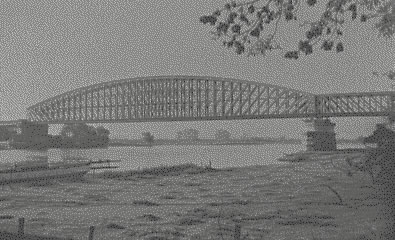

Parabolic truss systems

were also widely used, particularly for railway bridges. The "Lek Bridge" near Culenborg in the Netherlands had

the longest span of such girders for a long time. It was built in 1868,

using steel for the first time in bridges.

|

cantilever bridges, Gerber beams |

A special type of truss

structure is the cantilever bridge. By making the truss girder deeper at

the piers, cantilevers may be built far into the middle of the span.

This technique is of great importance when bridging deep or rough water.

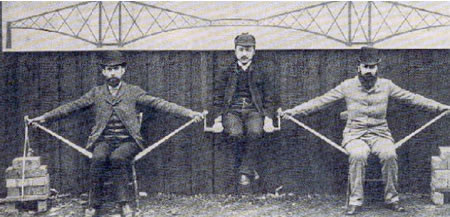

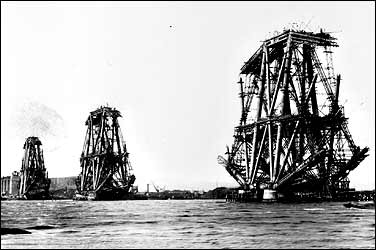

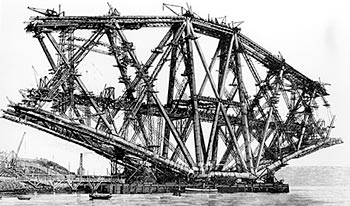

One of the greatest

cantilever bridges is the "Firth of Forth Bridge" in Scotland. When built

in 1883 - 1890 with main spans of 521 m, it gained the world record for

the longest span bridge.

The bridge, which today is

considered to be a unique and gigantic construction, is a masterpiece of

engineering work. The depth of the truss above the piers is 106 m, the

main tubular members are 3,7 m in diameter, and the whole bridge used

42.000 tons of steel and at times required up to 4.600 workers at the site

to undertake the complex method of construction.

The "Hooghly River Bridge"

in Calcutta, built in 1940 with a span of 455 m, is the fourth largest

cantilever bridge. Although a late example of this successful type of

bridge.

The bowstring arch through

truss bridge was patented in 1840 by Squire Whipple. Thrust arches

transform their vertical loads into a thrust along the arc of the arch. At

the ends of the arch this thrust (at a downward angle away from the centre

of the bridge) may be resolved into two components, a vertical thrust

equal to a proportion of the weight and load of the bridge section, and a

horizontal thrust. In a typical arch this horizontal thrust is taken into

the ground, while in a bowstring arch the thrust is taken horizontally by

a chord member to the opposite side of the arch. This allows the footings

to take only vertical forces, useful for bridge sections resting upon high

pylons.

After the exceptional

example of the Britannia Bridge, plate girder bridges remained within

spans of about 30 m. Fresh impetus was given by the development of welding

in constructional steelwork. The use of welding began in about 1925.

A tied arch bridge acts

like a beam structure, which is assisted in carrying load by an arch

behaving similarly to a curved upper chord of a truss, while the deck

girder acts like the lower chord. Arch and deck girder are simply

connected by hangers and form a structure which has considerable

constructional advantages compared to true trusses when bridging wide

single spans or carrying heavy loads.

Such bridges were

frequently used in the past, especially for heavy railway bridges. The

first long span bridges were built in Hamburg over the Southern Elbe

(1899) with four spans of 100 m.

|

railway suspension bridges |

Before discussing the

Roeblings in detail, some remarks should be made concerning the use of

suspension bridges for railways. The first attempt was made in 1830 by

building a chain bridge over the River Tees near Stockton for an extension

of the Stockton-Darlington line. The free span was 86 m, the calculated

live load 150 tons, but disappointingly under less than half of the load

the deflections were intolerably high. The Brooklyn Bridge was also designed

to carry railways.

After more than 100 years

since it was opened, the Brooklyn Bridge is still in use.

Nowadays, most rail

bridges are constructed in pre-stressed concrete. They may be effective

but are rarely as interesting!

|