'Work began

on the funicular in early 1929. The car bodies were not

initially fitted as the funicular was used to carry all of

the building materials for the construction of the lido,

below. Although initially water powered, it was soon

discovered that the balance would be lost when passengers

left or joined the cars at the half way station. As a

consequence, electric traction was installed, the powerful

winding mechanisms being imported from Switzerland.'

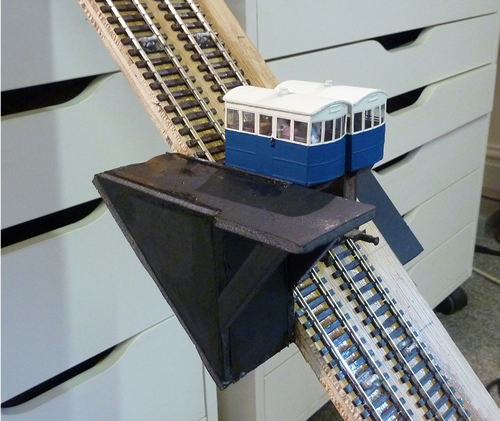

Construction

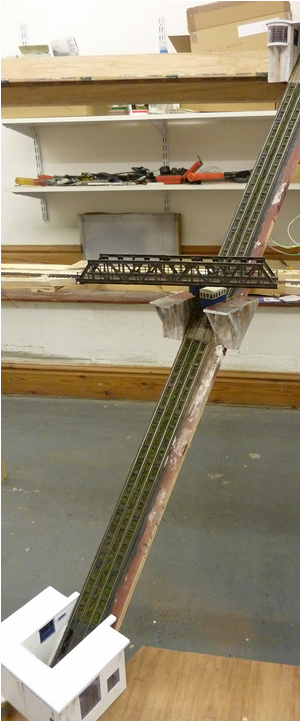

of the model was based on the Langley funicular kit. We did

not purchase the control unit as ours also had to stop midway.

The Langley model is designed to follow a slope of 45

degrees. It was not possible to incorporate a track of that

angle on Cliffhanger and our trackbed is actually 52

degrees. This necessitated a complete rebuild of the kit,

the chassis being taken apart and rejigged. I also built the

cars with curved ends which I felt was more compatible with

our art deco theme. I found the Langley instructions as

clear as mud, by the way.

I fitted

slatted seating to the cars; also from Langley. The water

tanks are filled with lead shot.

The completed cars -

click on image to enlarge

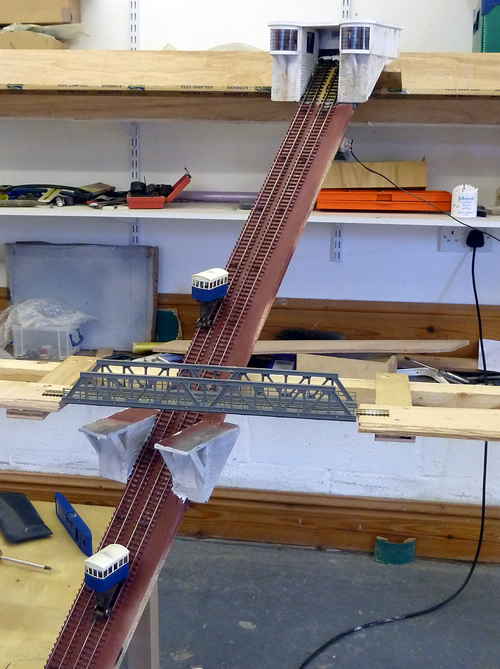

The 00 gauge

track was laid onto the funicular trackbed using a spacer to

ensure the correct distance between them. The whole arrangement was then set up at my

workshop at the correct angle and work was begun on building

the platforms and buildings.

click on image to enlarge

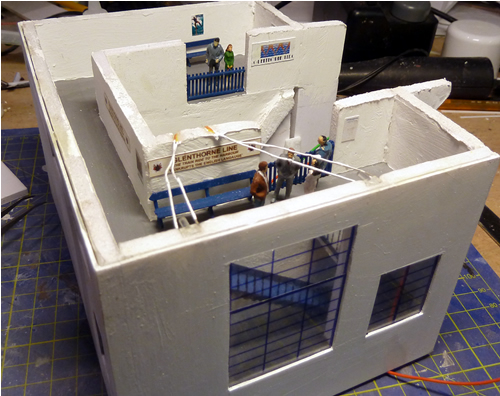

As the

funicular was built in 1929, I assumed that concrete would

have been the main construction material.

click on image to enlarge

Once the six

platforms were built in foamboard, they were coated in PVA.

A very thin coat of premix Polyfilla was then rendered over

them and a metal strip drawn across to leave marks depicting

shutter boards. The platforms are left removable at this

time for detailing and painting.

Finishing

was with acrylic washes and while the paint was still a

little damp, Eazi weathering powder was applied. This is by

far the best powder I have come across so far.

The top station was built in

foam board. The Crittall windows were printed on self

adhesive clear vinyl and stuck to transparent acrylic sheet.

A large 'CLIFF RAILWAY' sign is to be added to the roof. The

supports for the building are made of shuttered concrete

while the building itself is rendered concrete. Weathering

would have been quite rapid in these maritime conditions.

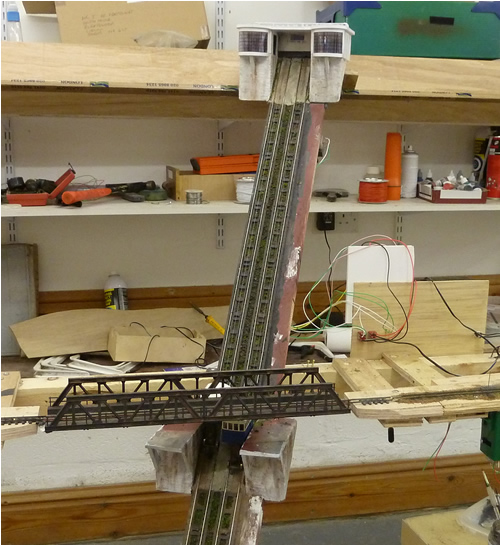

The funicular trackbed was then

offered up again to the baseboard and the top and middle

stations attached, ensuring that they were plumb. It then

became obvious that despite all our planning, the railway

bridge had been built 4" too far to the right. This was not a

hard job to put right luckily.

In the photo below, the track

and rollers have been painted.

The lower station under

construction. click on image to enlarge

The next step was to convert

the track to baulkway which is typical of funiculars. In the

photo below, the bridge is in its correct place and the

weeds between the baulkway can be seen.

The photo below shows the lower

station roughly in place. The roof over the tracks is not

yet built.

The

funicular is incorporated into the scenery

The fully

detailed track

The operation of the funicular

appeared to be simple indeed. Reed switches set into the

track would be operated by magnets fastened under the cars

and the whole would be controlled by a simple off-the-shelf

shuttle system. That is when the troubles began!

1. Fishing line was recommended

as cable. We discovered that all fishing line stretches and

the positioning of the cars was constantly changing. A move

to beading thread cured this particular problem.

2. We then discovered that reed

switches were not totally reliable. On occasion, the magnet

was not detected which resulted in a car being driven

against the back wall of the upper winding house. The cable

would break and the car crash to the bottom with the loss of

all hands!

3. We initially used the motor

supplied by Langley. This drove both cars from pulleys

attached to a common shaft. The motor was geared and was

difficult to control.

4. We found that the cable

would build up on one side of the pulley and then drop down

to the bottom of the V. This resulted in the car violently

dropping and then derailing.

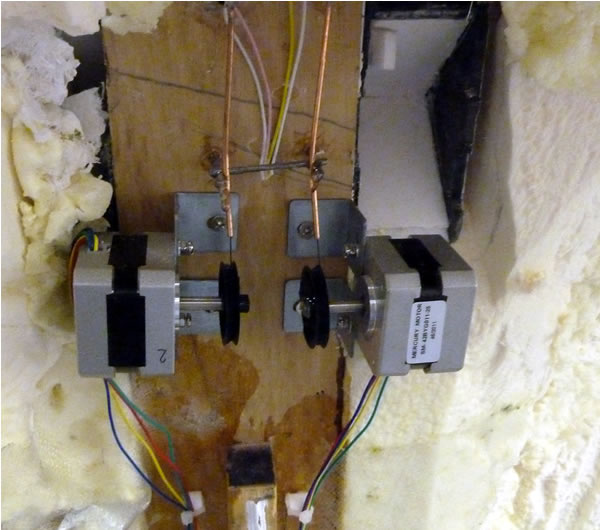

It quickly became obvious that

no amount of tweaking would improve the situation. Very

fortunately, Andy and Fiona Forty of DCC Supplies came to my

rescue. Two step motors were fitted. These motors count 200

positions per revolution. One revolution equals 1mm of

movement of the car. Electronics accurately count the

'clicks' so that the cars are always perfectly positioned.

The electronic hardware developed by Andy was programmed

using his laptop and we haven't looked back since.

My contribution was to solve

how to evenly lay the cable onto the pulleys. It was too

simple for words: build in pulley wobble!

The stepper motors. Positioning

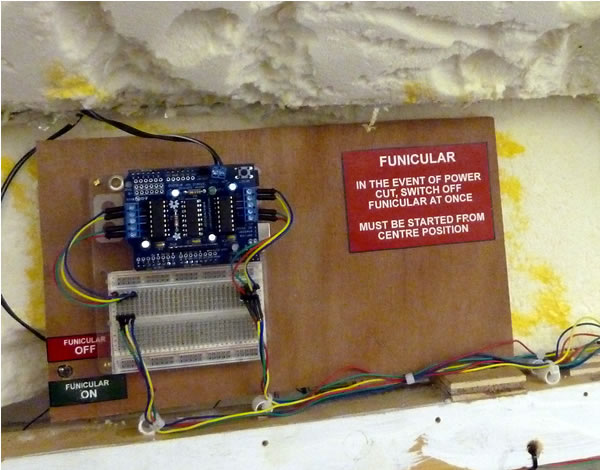

of the copper lead tubes is critical.

The one off electronic

control board developed by DCC Supplies.

It is essential that the

funicular is always started with the cars accurately

positioned at the mid way station. If it is started in any

other position, disaster will result. For this reason, we

have an uninterruptible power supply (UPS). In the event of

a short break in power supply, the funicular will continue

for a while and the UPS bleeps loudly. This gives us the

opportunity to stop the cycle with the cars in the correct

position.