|

the fiddle yard

We had been unhappy with the operation of

the front loading traverser which had a habit of slightly changing

dimensions due to temperature changes and tripping up trains. We also

found that visitors at exhibitions hated us obscuring the hotel with the

lift up lid when operating it. The traverser has now been removed.

Having converted to DCC we realised that we

could automate the main line running for exhibitions. This needed a six

road fiddle yard. All points are now to be controlled by 'loco-net'.

The aim is to allow different trains to

arrive from each direction at County Gate, cross and the disappear on

their way. The automation is by Railroad & Co software.

The first fiddle yard was supported on two

steel brackets from the display stands. Sadly, operation showed up some

flaws which has now resulted in the construction of a new unit.

The problems were

1. The fiddle table was too deep and could be distorted

if a person leant on it. This resulted in the derailment of trains at the

baseboard joint.

2. Despite being 7'6" long, some of the

loops were too short for comfort and restricted the choice of trains to be

run.

3. The Peco 12" Crazytrack turnouts

caused a number of derailments.

the old fiddle yard

Having gained experience in operation, the

existing fiddle yard was withdrawn following our exhibition at Wigan in

December. The new yard would be much narrower but span the length

of two long baseboards (15') in two sections. It is supported by

removable brackets attached to the metal display stands. A third

board is also be provided behind the hotel section which supports

the laptop computer and gives us some space to work.

The pointwork is 18" radius N gauge

track and small track sections with movable fishplates join the track

to the main board. Additional siding are also provided at the hotel end of

the board.

The advantage to this system is that apart

from having longer loops, the trains are much closer to the hotel end thus

reducing off scene running time. Another important factor

is that the new narrow boards afford us much better access behind the

scenes being substantially narrower.

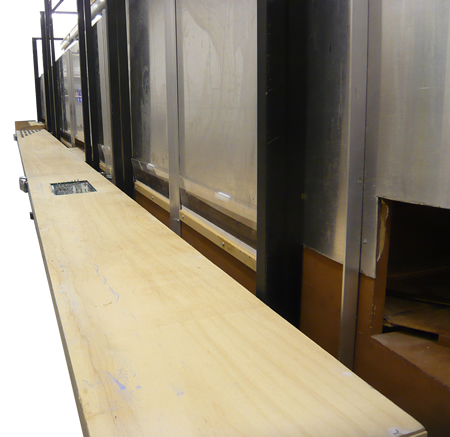

the new 15 ft yard under construction

This does show how tight clearances are on

the new yard. The track will be ballasted when all wiring is complete.

Sadly, I forgot about the duckouts on the brake coaches. I was forced to

remove the ones on the blind side.

One of the problems with the first fiddle

yard were the oblique angled track joints between the layout and the yard.

The smallest variance would result in derailments and constant attention

was needed to preserve alignment during running. This time. the connecting

tracks are removable lengths of track with right angled joints. The

ends of the fixed track both on the layout and on the yard are soldered on

to PCB board, (insulated by a saw cut).

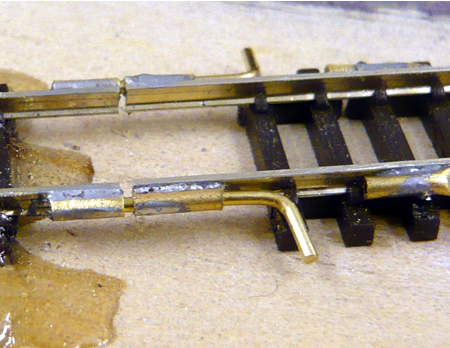

The rails have 'mini bolts' soldered to them

in 1.5mm brass tube and 1mm brass rod.

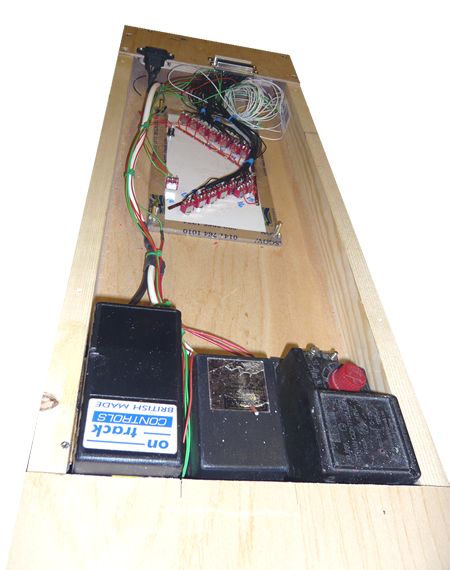

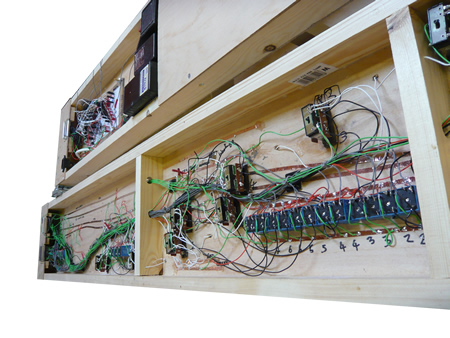

Some revamping of the wiring was required.

We finally had to provide a CDU for each point. This was necessary to

enable route selection in automation mode. The CDUs are fed by 3

transformers!

the new manual panel for the fiddle yard

board 1 (behind hotel) which has the

manual control panel and transformers - click on image to enlarge

the entire fiddle yard boards installed

with register pins and the rest of the track laying can be completed

the wiring complete on two of the

boards

most of the trackwork now laid

The completed ballasted trackwork now laid

Some may consider it strange that the fiddle

yard is ballasted. This is done to stabilise the track when taken to

venues of very different temperatures. It also looks a whole lot better!

the fiddle yard being tested with a

railcar motor unit - the edging and finishing still remains to be done

the fiddle yard populated

built in track cleaner on fiddle yard

|