|

making a house

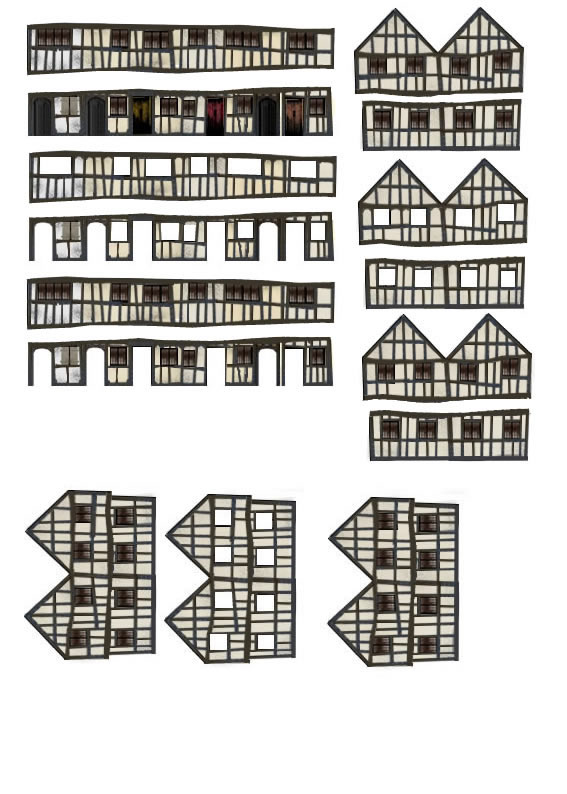

The first sheet is printed on

high quality photo paper and the rest on Premium Photo

glossy which is thin card. These are cut out and glued

together with PVA which results in a most rigid and stable

structure.

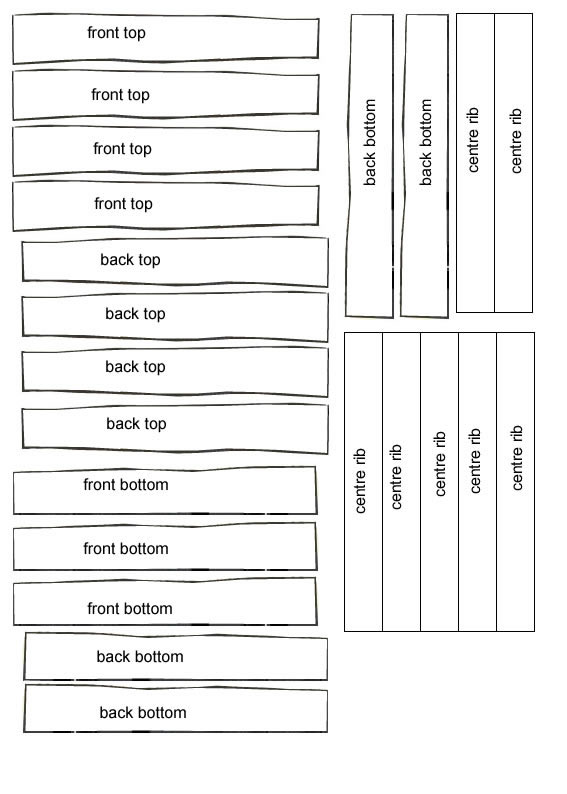

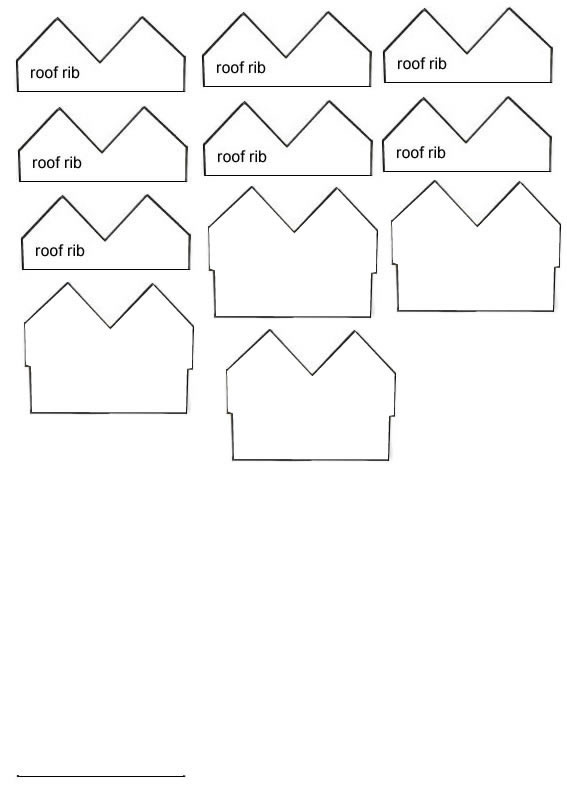

The photo below shows the sequence of layer

application (starting with '1'). Early Tudor windows were almost flush so in

this case there is just a paper thickness. Prior to gluing together, the cut

edges are painted with the right colour.

The layers are put together by painting PVA to

the back of the sheets. It is quite hard to line up the paper sheets and

care is needed. Once assembled and pressed together, excess PVA is removed

using cocktail sticks. Any touch up with paint is also done at this time. I

usually carefully repaint the reveals. One window has shutters. The final

ones will be glued on later.

Then while still a bit damp, I apply weathering powders with a small stiff

brush and then place the assembly in a press for an hour.

Once the PVA has dried hard, the edges of each

assembly are sanded flush to the mark line of the top lamination. Obviously,

with so many laminations, not all will be quite in register. Always make

sure that the sander rotates towards the back of the panels to prevent the

surface paper making swarf on the surface. Where necessary, reverse the

rotation of the sander.

Where jointed to another panel, the ends are

mitred again using the Dremel sander.

So now to assembly. I use mostly gel type

superglue which is bought in vast quantities along with activator. Liquid

superglue can too easily run onto the printed surfaces and ruin them.

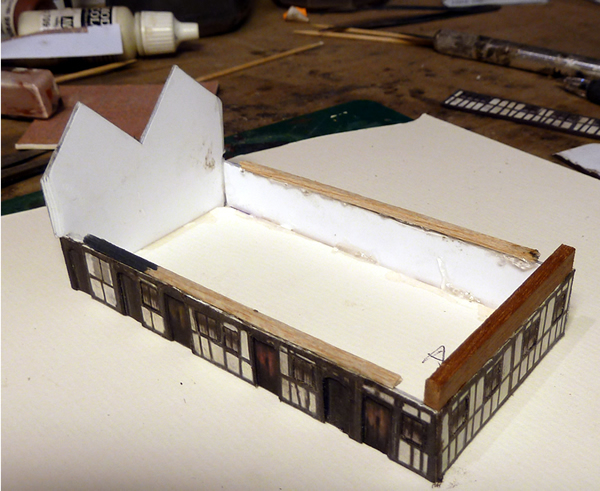

The ground floor is put together making sure

that the mitres are accurately fitted and a base in mount board is glued

into the bottom to hold it all nice and square. Strips of wood are glued

onto the top of the lower story to give attach points to the jettied upper

story.

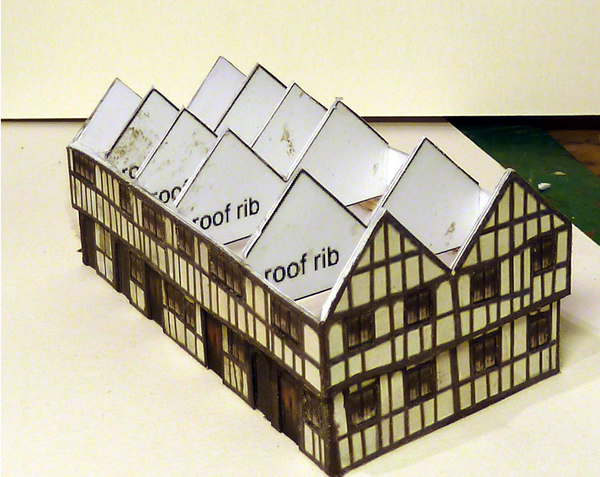

Here the upper story is glued in place.

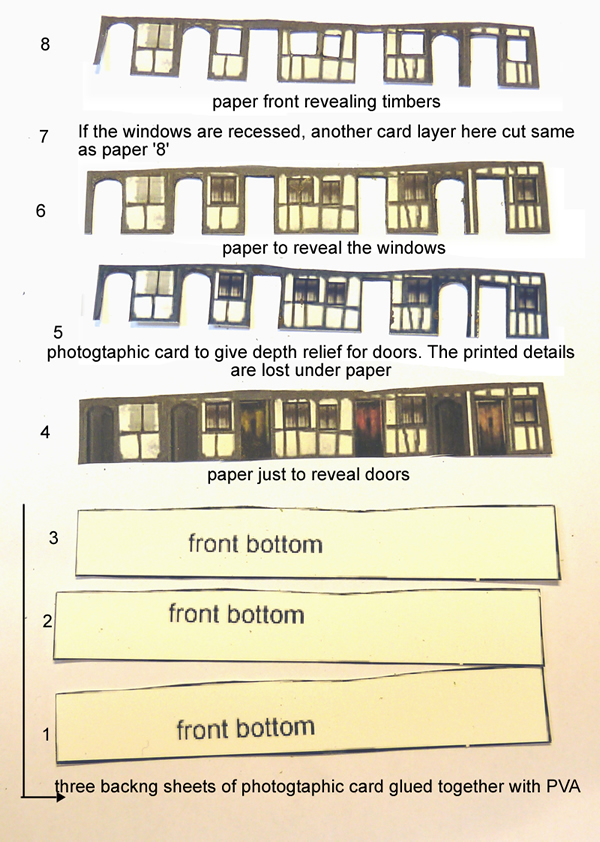

The trusses are now fixed. In this case, care

has been taken to make sure they are not all in nice straight lines as the

roof has to be 'wonky'.

Normally, my roofs are attached to mount board. Its thickness serves to copy

bargebaords. For the 'wonky' roof, the tile paper is attached to cornflake

packet which is far more flexible. The tile paper is attached to the card

backing using spray mount, by the way.

Once a roof section is cut, the visible underside is painted and then the

roof fitted. The glue is placed on one surface and the other is flooded with

accelerator. The accelerator does not damage the model at all but does make

one cough!

The roofs are glued into place followed by the

chimneys. Weathering of the model then follows.

|