|

Structures

I always

prefer to start with the structures as these do take time

but are easily stored. This minimised the length of time

that baseboards dominate the scenery! The station building

will be made using Wills plastic sheets. I have some scale drawings produced by Chris Ashmore. These

are produced to a scale of 7mm/ft and will have to be

reduced down to 4mm/ft. I also Have drawings produced by

Chris Leigh for 4mm/ft.

The station

walls were constructed using Wills random stone sheets,

Wills industrial arches, Ratio gutters and down pipes and

Wills and Ratio windows and doors. I also used various

thicknesses of plastic sheet. The Ratio windows needed a bit

of butchery by moving the horizontal glazing bars. They were

then spray painted cream and the doors, green.

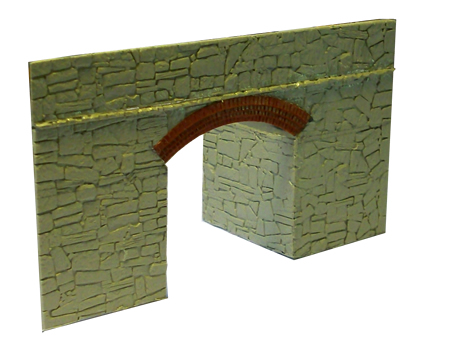

One thing

that I see over and over again, are Wills brick arches glued

to the surface of building sheets. This leaves them standing

out proud rather than being flush with the building sheet.

The arches are supplied marked only with alternate bricks.

The intermediate bricks need to be carved out using a

scalpel. The arches are cut to size with two being glued

together to increase the thickness. The lower edge is carved

to show the brick courses.

This

procedure takes more time but the end result is far better.

The corners

of the walls are mitred. These are glued together using

Plastic Weld while being assembled around a pre-cut floor of

plastic sheet. Once the paint is dry, the windows are glazed

using the clear plastic sheet from the Wills packaging.

Before the

widows and doors are fitted, the stonework must be painted.

I now only use water based acrylic paints and first paint

the blocks a variety of browns. While the paint is still

damp, I apply brown weathering power. Various greys are then

dry brushed over the surface. Once dry, I damp the walls

with a mister (detergent added) and run dilute white paint

into the mortar gaps. This runs most satisfactorily down the

walls representing mortar, although more than one

application may be needed. The surface of the stones is then

dabbed with paper towels until a realistic finish is

obtained. The brickwork is picked out in a variety of

colours as required. This process considerably lightens the

stone finish, so this must be allowed for during the initial

painting.

Interior

wall were then added with whatever detail I chose to

include.

The windows

and doors can then be fitted, being supported by square

section Plastistrut on the inside.

The roof is built using 1mm

thick plastic sheet. As always, hip roofs are more

challenging and care is needed to ensure that the pitches

are correct. The roof has a considerable overhang. This is

why I built the walls of the building so high so that they

support the roof at the correct height.

The unusual diagonal slates

were added only where they would be seen (due to snow

slippage) and ridges were fitted. This building has ornate

ends to the ridge tiles which were carved out of solid

plastic. The single chimney was added at the rear.

basic structure of the

station completed

with the hip roof completed,

the first coats of Woodland Scenics 'snow' is added

Barring some details, the

building is finished and snow applications continue. The

climbing plants must also be affixed to the walls.

the completed snow

application using microballoon.

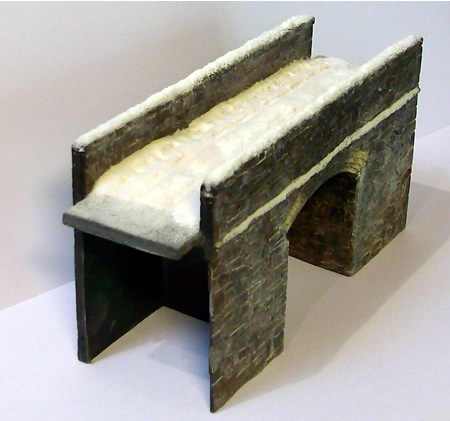

the bridge

The bridge is

still extant. Construction was again in

plastic.

the completed snow

application using microballoon.

the

goods shed

With

only one known photo of this structure, a lot of the

model is guesswork.

the goods shed under way.

The snow bulk is

made up with Woodland Scenics 'white gravel' Many

further treatments will be needed to have 'real snow' .

the completed snow

application using microballoon.

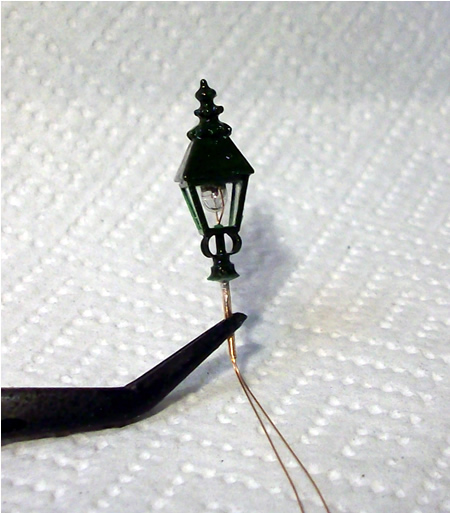

lighting up

There are three

lamps at Bratton Fleming and I spent some

time searching for good representations of

those used. As we are modelling day and

night, these lamps have to work, of course.

Head and shoulders above all others were

from

DCC Concepts based in Oz. I later

discovered that they are supplied in the UK

by DCC Supplies.

SR gas lamps

were ordered and arrived in a pack of three

with extension posts and a circuit board

which allows you to adjust the light

intensity. The quality of these things is

better than anything else I have seen (UK

white metal caters take note).

The colour

seems to me to be a tad lurid but this was

easily put right by some very careful

painting. A word of warning: use water based

acrylic paint as enamels, for some reason

will not dry matt. One lamp is mounted on

the Gents wall at the station and therefore

has no pole. This I removed by sanding it

with a Dremel. In the centre is a very fine

brass tube in which are the two thin power

wires. Handle these carefully to prevent

damaging the insulation. Once the pole was

removed, I continued to carefully sand the

brass tube until it nearly cut through. It

then very easily breaks off.

The small

copper wires were cut short, the insulation

scraped off at the ends and soldered to thin

insulated multi-strand wires. The toilet

wall was routed to half thickness and a

small hole drilled in the floor of the loo

to let the wires through. The lamp was then

epoxied in and snowed up. A further lamp was

modified to become a wall mounted unit,

while the third was fitted as the stand

alone lamp near the footpath entrance to the

station.

Warm white LEDs

were also installed in the building using

3Kohm resistors to maintain the lights dim.

the station

with lamp attached - click on image to

enlarge

|